Preparation method of cerium oxide hexagonal nanometer sheet structure

A nanosheet-like, hexagonal technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

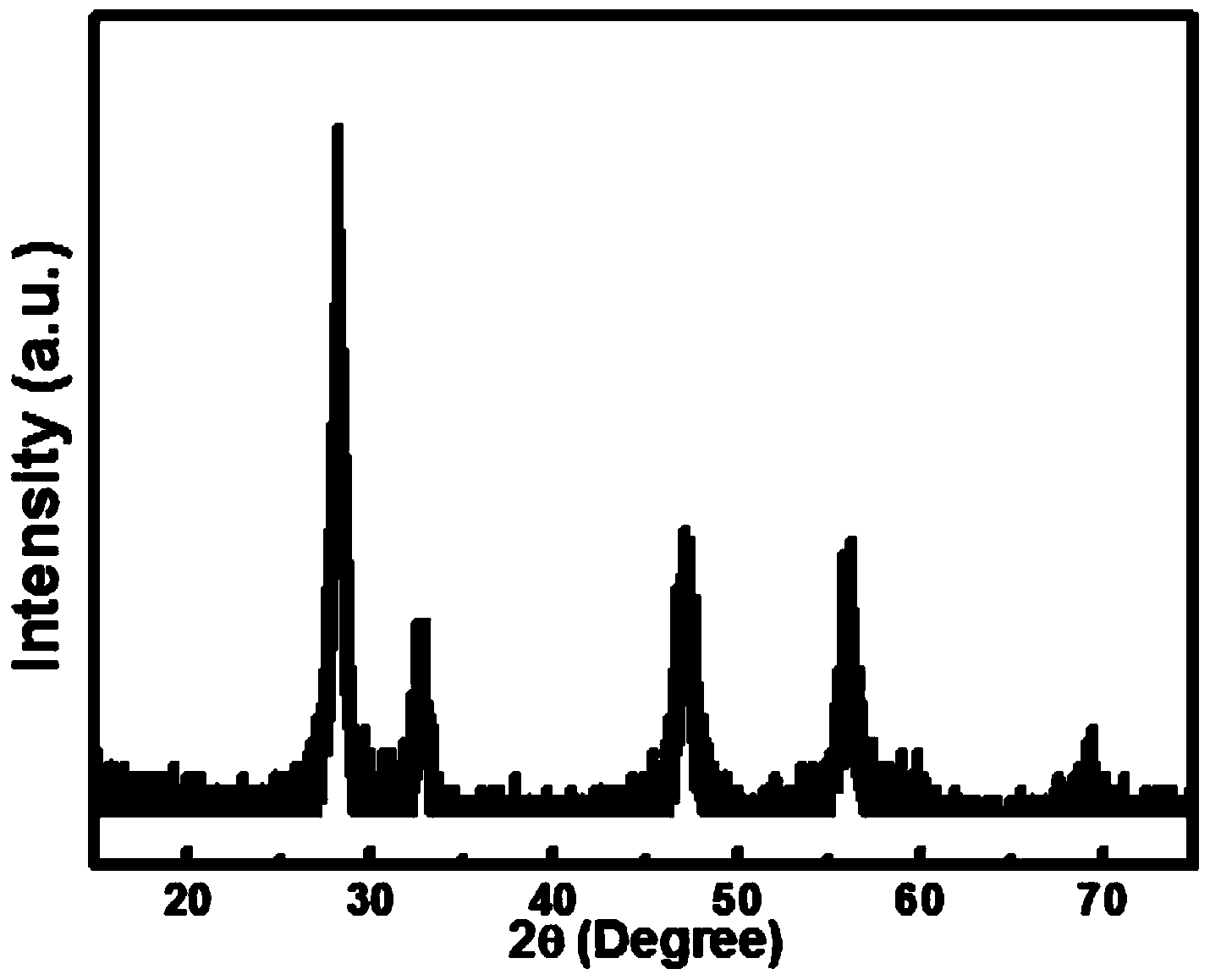

[0014] A preparation method of cerium oxide hexagonal nanosheet structure, comprising the following steps:

[0015] (1) 1.4903g CeCl 3 ·7H 2 O was added to 10mL distilled water, stirred and mixed to form a liquid;

[0016] (2) Add 4.7430g of urea into 15mL of distilled water, stir well for 15min, mix with the above liquid a, stir well for 30min, add 10mL of ethylenediamine, stir for another 30min, transfer to a 50mL high-temperature reactor, and react at 120°C for 48h After the reaction, wash with water and alcohol alternately for 3 times, and finally anneal at 400° C. for 5 hours to obtain the cerium oxide hexagonal nanosheet structure with a diameter of 500-800 nm.

Embodiment 2

[0018] A preparation method of cerium oxide hexagonal nanosheet structure, comprising the following steps:

[0019] (1) 1.4903g CeCl 3 ·7H 2 O was added to 10mL distilled water, stirred and mixed to form a liquid;

[0020] (2) Add 4.7430g of urea into 15mL of distilled water, stir well for 15min, mix with the above liquid a, stir well for 30min, add 10mL of ethylenediamine, stir for another 30min, transfer to a 50mL high-temperature reactor, and react at 140°C for 48h After the reaction, wash with water and alcohol alternately for 3 times, and finally anneal at 400° C. for 5 hours to obtain the cerium oxide hexagonal nanosheet structure with a diameter of 500-800 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com