Preparation method of hydro-thermal coupling spray pyrolysis MnO2/graphene electrode material

A graphene electrode and spray pyrolysis technology, applied in the field of nano-electrode materials for energy storage systems, can solve problems such as volume expansion of transition metal oxide materials, difficult industrialization of sol-gel methods, and uneven mixing of high-temperature solid-phase methods. Achieve good electrochemical performance, good practical value and market prospects, and high product quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

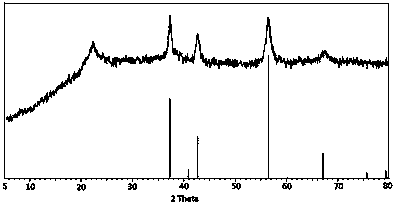

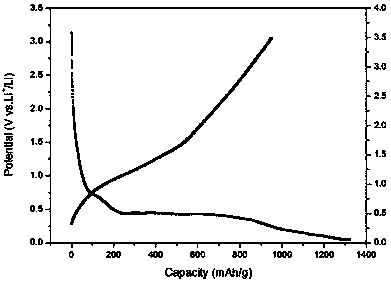

[0032] Preparation of Nano-MnO as Lithium Battery Electrode Material 2 / graphene composite, proceed as follows:

[0033] (1) With graphite, potassium permanganate, H 2 SO 4 / H 3 PO 4 (volume ratio 9:1) and H 2 o 2 As a raw material, graphite oxide (GO) was prepared by the improved Hummers method, and the obtained GO had a multilayer 5×5 μm flake structure;

[0034] (2) Take 0.005g of GO prepared in step (1), add 20mL of deionized water, and sonicate for 0.5hr at 200w power to obtain a uniform GO deionized water dispersion;

[0035] (3) Using potassium permanganate and manganese acetate as raw materials, weigh 0.3g potassium permanganate and 0.7g manganese acetate, add 30mL deionized water, add 20mL GO deionized water dispersion prepared in step (2), 20mL 0.001M Ni(NO 3 ) 2 Solution, 0.1g sodium lauryl sulfate, ultrasonic 0.5hr, form a uniform mixed solution, put it into a hydrothermal kettle, control the reaction temperature to 250°C, and continue the reaction time fo...

Embodiment 2

[0042] Preparation of Nano-MnO as Lithium Battery Electrode Material 2 / graphene composite, proceed as follows:

[0043] (1) With graphite, potassium permanganate, H 2 SO 4 / H 3 PO 4 (volume ratio 9:1) and H 2 o 2 As a raw material, graphite oxide (GO) was prepared by the improved Hummers method, and the obtained GO had a multilayer 5×5 μm sheet structure;

[0044] (2) Take 0.05g of GO prepared in step (1), add 20mL of ethanol, and sonicate at 200w power for 1hr to obtain a uniform GO dispersion;

[0045] (3) Using potassium permanganate and manganese acetate as raw materials, weigh 1.6g of potassium permanganate and 3.7g of manganese acetate, add 30mL of deionized water, 0.3g of sodium lauryl sulfate, and add 20mL of step (2) to prepare GO dispersion, 20mL 0.025M Ni(NO 3 ) 2 The solution was ultrasonicated for 1 hr to form a uniform mixed solution, placed in a hydrothermal kettle, the reaction temperature was controlled at 160°C, and the reaction time was continued f...

Embodiment 3

[0052] Preparation of Nano-MnO as Lithium Battery Electrode Material 2 / graphene composite, proceed as follows:

[0053] (1) With graphite, potassium permanganate, H 2 SO 4 / H 3 PO 4 (volume ratio 9:1) and H 2 o 2 As a raw material, graphite oxide (GO) was prepared by the improved Hummers method, and the obtained GO had a multilayer 5×5 μm flake structure;

[0054] (2) Take 0.2g of GO prepared in step (1), add 20mL of deionized water, and ultrasonicate for 2 hours at 200w power to obtain a uniform dispersion of GO in deionized water;

[0055] (3) Using potassium permanganate and manganese acetate as raw materials, weigh 3.2g of potassium permanganate and 7.5g of manganese acetate, add 30mL of deionized water, 0.5g of polyvinyl alcohol, and add 20mL of GO prepared in step (2). Ionic water dispersion, 20mL 0.08mol / L Ni(NO 3 ) 2 solution, sonicated for 2 hours to form a uniform mixed solution, put it into a hydrothermal kettle, control the reaction temperature to 180°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com