Steel rail polishing vehicle

A rail grinding vehicle and grinding vehicle technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of high cost and complex structure, and achieve the effects of low maintenance cost, correcting wavy wear of the track, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] Rail grinding car of the present invention, its preferred embodiment is:

[0015] It includes a frame body, a grinding unit is arranged on the frame body, a running wheel is arranged on the lower part of the frame body, the frame body is suspended on a grinding train, and the distance between the frame body and the grinding train is There is a lifting hydraulic cylinder between them.

[0016] A locking device is provided between the frame body and the grinding train.

[0017] A traction device is provided between the frame body and the grinding train, one end of the traction device is hinged to the grinding train, and the other end is hinged to the frame body.

[0018] The rail grinding vehicle is a rail profile grinding vehicle or a corrugated grinding vehicle.

[0019] The rail profile grinding vehicle includes four groups of grinding units, and each group of grinding units includes two grinding heads.

[0020] The corrugation grinding vehicle includes two groups o...

specific Embodiment

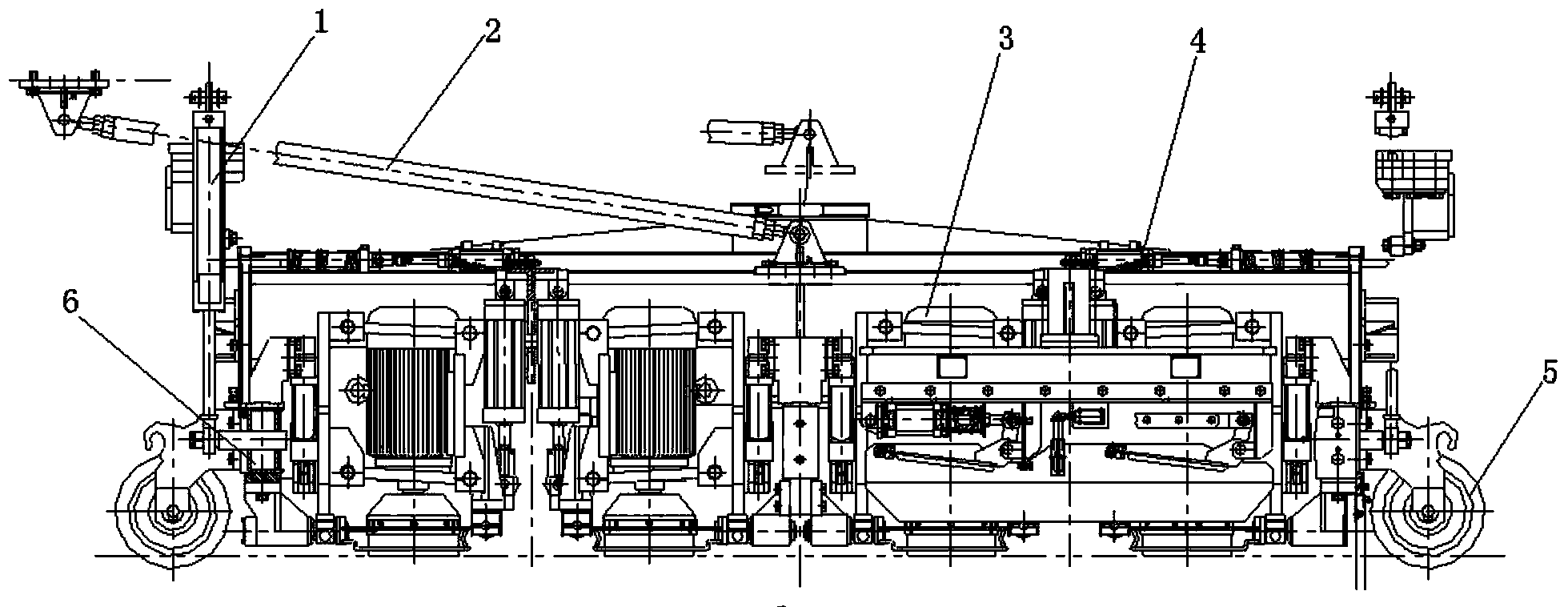

[0021] Such as figure 1 As shown, it includes a welded frame (frame body), four lifting hydraulic cylinders for controlling the lifting of the trolley, a locking device, a traction device, and a deflectable grinding unit. The frame body features four rimmed wheels that ride on rails while sanding. The traction device realizes two-way traction operation through a tow bar.

[0022] During the grinding operation, the grinding motor of the grinding unit is lifted, the locking device is unlocked, the trolley falls into the rail surface under its own weight, the deflection angle of the grinding unit is set, and the motor drives the grinding wheel to grind the rail surface.

[0023] The rail grinding car includes a rail profile grinding trolley and a wave grinding trolley. The main difference is that the grinding units are different. The rail profile grinding trolley has four sets of grinding units, while the corrugation grinding trolley has two sets of grinding units. The other par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com