Crystal growing device and crystal manufacturing method

A manufacturing method and technology for crystal growth, applied in crystal growth, chemical instruments and methods, during the use of growth, the seed crystal is retained in the molten liquid and other directions, which can solve problems such as dislocation and affect crystal quality, reduce thermal stress concentration, and improve crystal. Quality, improve the effect of adjustable interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The invention relates to a crystal growth device and a crystal manufacturing method. First, a brief description of the crystal growth device used in the crystal manufacturing method will be given, and then the crystal manufacturing method will be introduced.

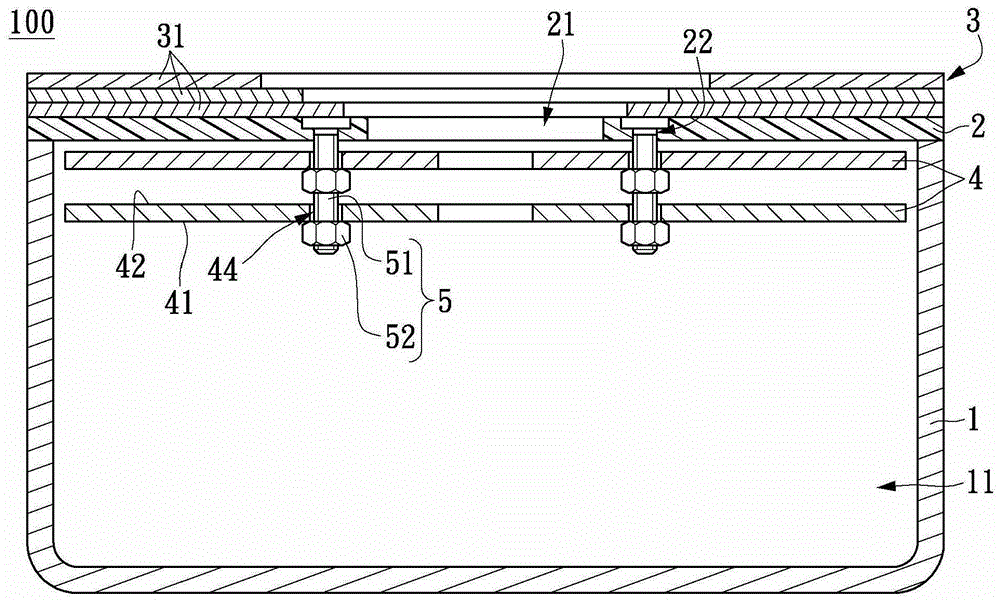

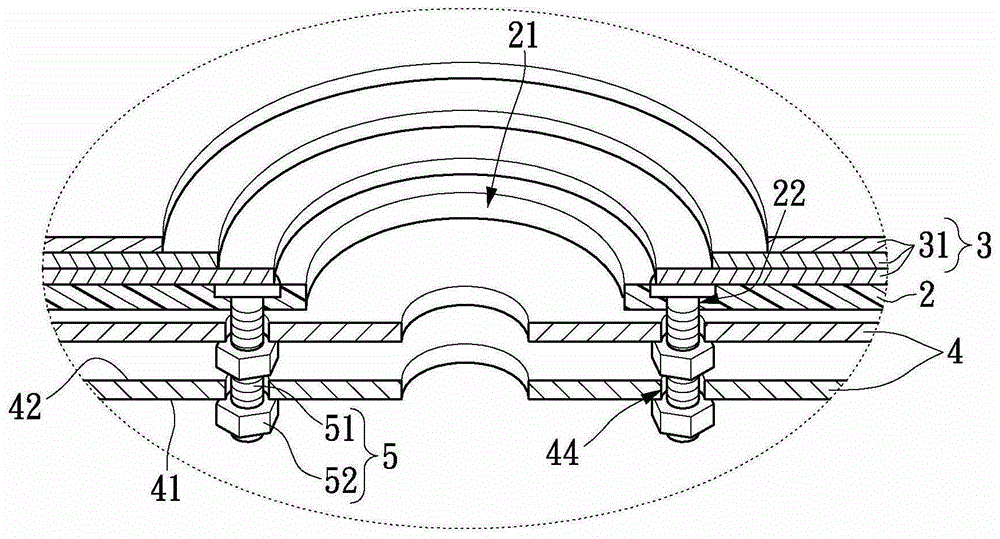

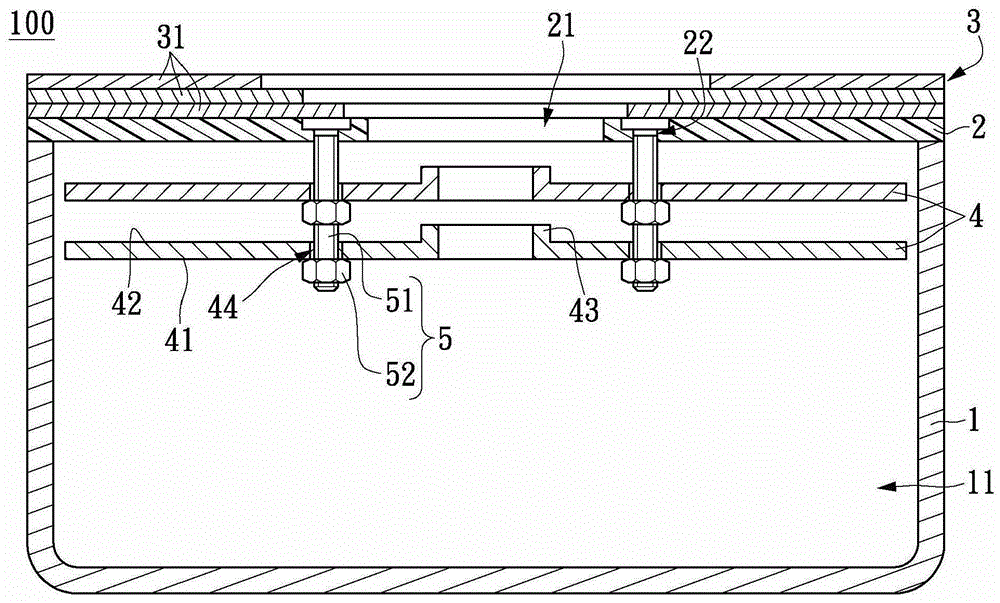

[0045] see Figure 1A and Figure 1B As shown, it is an embodiment of the present invention. This embodiment provides a crystal growth device 100, including: a crucible 1, a crucible cover 2, a heat insulation unit 3, a plurality of heat reflection rings 4 and a suspension Unit 5. Wherein, the above-mentioned crucible 1 is a commonly used appliance in the industry, so it will not be described in detail here.

[0046] A substantially central portion of the crucible cover 2 defines an opening 21 , and a plurality of through holes 22 are formed in the crucible cover 2 adjacent to the opening 21 . The crucible cover 2 is installed on the crucible 1 so that the crucible 1 and the crucible cover 2 surround and define...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com