Ingot mould, smelting system and production method of large ingot type alloy ingot

A production method and ingot mold technology, applied in the field of metallurgy, can solve the problems of large impact of metal casting stream on refractory lining, slag inclusion at the bottom, etc., and achieve the effects of improving ingot quality, reducing temperature gradient, and less cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

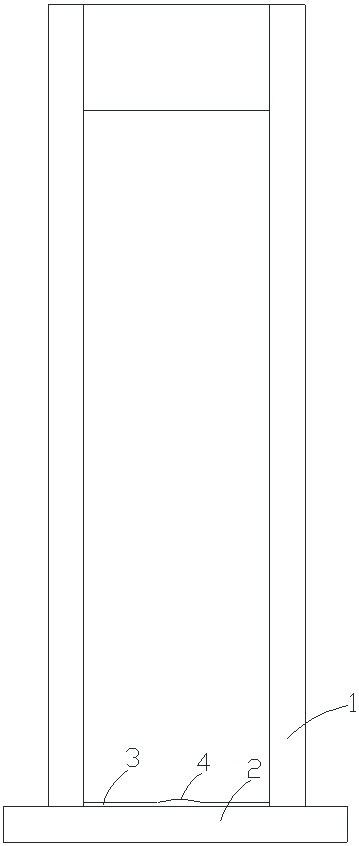

[0053] Such as figure 1 As shown, the present embodiment provides an ingot mold, which includes an ingot mold body 1. The ingot mold body 1 is cylindrical as a whole, and the bottom of the ingot mold body 1 is sequentially provided with a refractory backing 2 and a metal bottom pad 3. The thickness of the metal bottom pad 3 is is 5mm. A circular arc-shaped protrusion 4 is arranged in the center of the metal bottom pad 3 .

[0054] Present embodiment also provides a kind of diameter is the production method of the GH4738 ingot of 580mm, comprises the following steps:

[0055] According to the composition control requirements of superalloy GH4738, calculate the required quality of various raw materials according to the mass percentage and ensure that all raw materials are clean and free of oil.

[0056] The alloy is smelted in a vacuum induction furnace. What needs to be explained is that all processes before casting of GH4738 in vacuum induction smelting, such as batching, ch...

Embodiment 2

[0062] The difference from Example 1 is that in this example, the ingot mold body 1 is baked to 600° C. and kept at this temperature for 4 hours.

Embodiment 3

[0064] The difference from Example 1 is that in this example, the ingot mold body 1 is baked to 800° C. and kept at this temperature for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com