Nuclear-environment-resistant cable insulation material and preparation method thereof

A cable insulation and environmental technology, applied in the field of cables, can solve problems such as difficult service life, damage to cable materials, damage to personnel and equipment, etc., and achieve good long-term thermal aging resistance, good electrical insulation performance, and good flame retardancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

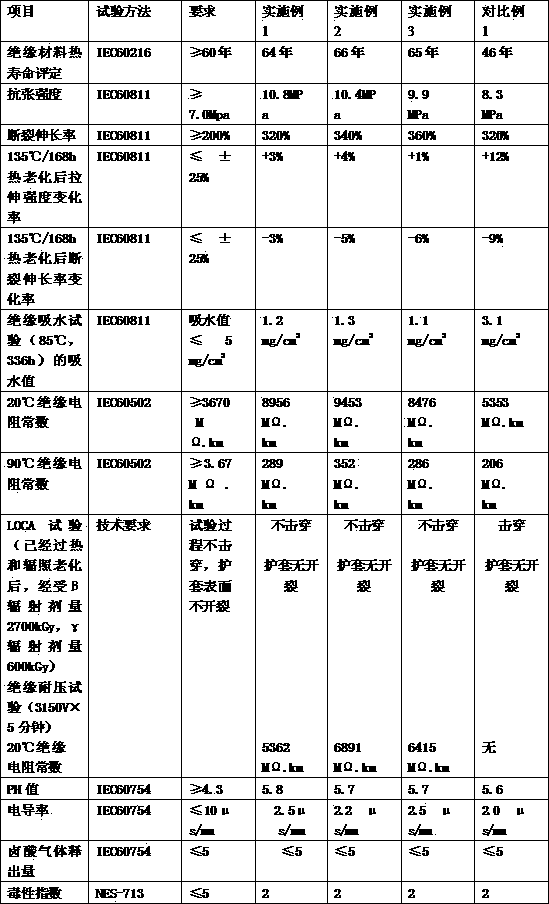

Examples

preparation example Construction

[0040] The preparation method of the nuclear environment resistant cable insulating material of this example, the steps are as follows:

[0041] 1) Weigh the raw materials of the cable insulation material according to the formula;

[0042]2) Then mix the binary ethylene propylene rubber methyl methacrylate copolymer, the mixture of nano-aluminum hydroxide and aluminum hydroxide, and vinyl tris(β-methoxyethoxy)silane in the disperser at (500 Stirring at a stirring speed of ±50) rev / min;

[0043] When stirring, first preheat the disperser to 70-75°C, then feed and stir the mixture of nano-aluminum hydroxide and aluminum hydroxide for 4-6 minutes; then add vinyl tris(β-methoxyethoxy) Silane, stir for another 5 to 7 minutes; finally add binary ethylene propylene rubber methyl methacrylate copolymer, stir for another 4 to 6 minutes before unloading;

[0044] 3) Mix the product obtained in step 2) with paraffin wax and microcrystalline wax in an internal mixer, N,N'-bis(2,2,6,6-te...

Embodiment 1

[0050] A cable insulating material resistant to nuclear environment, which is composed of the following substances in parts by mass:

[0051] 100 parts of binary ethylene propylene rubber methyl methacrylate copolymer;

[0052] 10 parts of nano aluminum hydroxide;

[0053] 125 parts of aluminum hydroxide;

[0054] 15 parts of calcined kaolin;

[0055] 1.0 parts of 2,2,4-trimethyl-1,2-dihydroquinoline;

[0056] 2.8 parts of N-isopropyl-N'-phenyl-p-phenylenediamine;

[0057] 1.5 parts of N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-benzenedicarboxamide;

[0058] 1 part of 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole;

[0060] 2.5 parts of paraffin;

[0061] 3.5 parts of microcrystalline wax;

[0062] 2.5 parts of vinyl tris (β-methoxyethoxy) silane;

[0063] 3.0 parts of 2,5-dimethyl-2,5-diperoxy-tert-butylhexane;

[0064] 1.2 parts of triallyl isocyanurate.

[0065] The preparation method of the above-mentioned nuclear environment...

Embodiment 2

[0068] A cable insulating material resistant to nuclear environment, which is composed of the following substances in parts by mass:

[0069] 100 parts of binary ethylene propylene rubber methyl methacrylate copolymer;

[0070] 13 parts of nano aluminum hydroxide;

[0071] 132 parts of aluminum hydroxide;

[0072] 20 parts of calcined kaolin;

[0073] 1.5 parts of 2,2,4-trimethyl-1,2-dihydroquinoline;

[0074] 3.0 parts of N-isopropyl-N'-phenyl-p-phenylenediamine;

[0075] 2.0 parts of N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-benzenedicarboxamide;

[0076] 1.6 parts of 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole;

[0077] 6.0 parts of zinc oxide;

[0078] 4.0 parts of paraffin;

[0079] 5.0 parts of microcrystalline wax;

[0080] 3.5 parts of vinyl tris (β-methoxyethoxy) silane;

[0081] 3.5 parts of 2,5-dimethyl-2,5-diperoxy-tert-butylhexane;

[0082] Triallyl isocyanurate 1.6 parts.

[0083] The preparation method of the insulating material for nuclear-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com