Nonionic water-based epoxy curing agent and preparation method thereof

A non-ionic, water-based epoxy technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve problems such as poor water resistance, flash rust on metal bodies, and influence on coating stability, so as to increase controllability and safety. Improved water resistance and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

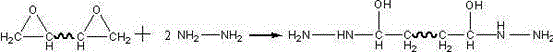

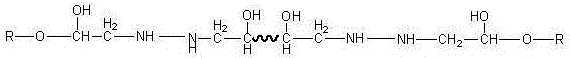

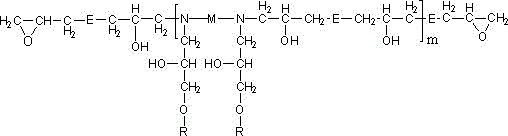

Method used

Image

Examples

Embodiment 1

[0051] Prepare raw materials according to the following components and their mass percentages in the total materials:

[0052] Component mass percentage (wt.%)

[0053] E-5112%

[0054] Prepolymer A36%

[0055] Triethylenetetramine 14.1%

[0056] Deionized water and propylene glycol methyl ether 22%

[0057] Phenyl glycidyl ether 15.9%

[0058] Among them, the raw material mass percentage of prepolymer A is:

[0059] E-5112%

[0060] ED-200340%

[0061] Dodecyl to tetradecyl glycidyl ether 12%

[0062] Propylene glycol methyl ether 36%

[0063] (1) Preparation of prepolymer A

[0064] In a reactor equipped with reflux, heating and stirring devices, put 40g amino-terminated polyether ED-2003 and 36g propylene glycol methyl ether solution, heat up to 60~70℃, drop 12g dodecyl to tetradecyl glycidyl ether, The 30min dripping is completed, and the temperature is controlled at 80~90℃ to react for 3h. At the end of the reaction, the temperature is reduced to room temperature. 12g epoxy resin E-51 is ...

Embodiment 2

[0073] Prepare raw materials according to the following components and their mass percentages in the total materials:

[0074] Component mass percentage (wt.%)

[0075] E-5113.2%

[0076] Prepolymer A33.1%

[0077] Diethylenetriamine 11.5%

[0078] Deionized water and propylene glycol methyl ether 29.1%

[0079] Butyl glycidyl ether 13.1%

[0080] Among them, the raw material mass percentage of prepolymer A is:

[0081] E-4445%

[0082] Epoxy resin emulsifier 15%

[0083] Deionized water 35%

[0084] Butyl glycidyl ether 5%

[0085] (1) Preparation of prepolymer A

[0086] In a reactor equipped with reflux, heating and stirring devices, put in 30g amino-terminated polyether ED-900 and 37g propylene glycol methyl ether solution, heat up to 65~75℃ and add 13g butyl glycidyl ether dropwise, 30min drop completion, The temperature was controlled at 80~90℃ to react for 3h. After the reaction, the temperature was lowered to room temperature. 20g epoxy resin E-44 was added, and the temperature was con...

Embodiment 3

[0095] Prepare raw materials according to the following components and their mass percentages in the total materials:

[0096] Component mass percentage (wt.%)

[0097] E-514.7%

[0098] Prepolymer A48%

[0099] Isophorone diamine 23.4%

[0100] Deionized water and propylene glycol methyl ether 16.1%

[0101] Butyl glycidyl ether 7.8%

[0102] Among them, the raw material mass percentage of prepolymer A is:

[0103] E-5167%

[0104] Epoxy resin emulsifier 16%

[0105] Deionized water 17%

[0106] Epoxy thinner 0%

[0107] (1) Preparation of prepolymer A

[0108] In a reactor equipped with reflux, heating and stirring devices, put 30g amino-terminated polyether ED-600 and 25g propylene glycol methyl ether solution, heat up to 65~75℃, add 19g butyl glycidyl ether dropwise, 30min drop completion, And the temperature is controlled at 80~90℃ to react for 3h, after the reaction, the temperature is cooled to room temperature, 26g epoxy resin is added, and the temperature is controlled at 80~90℃ to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com