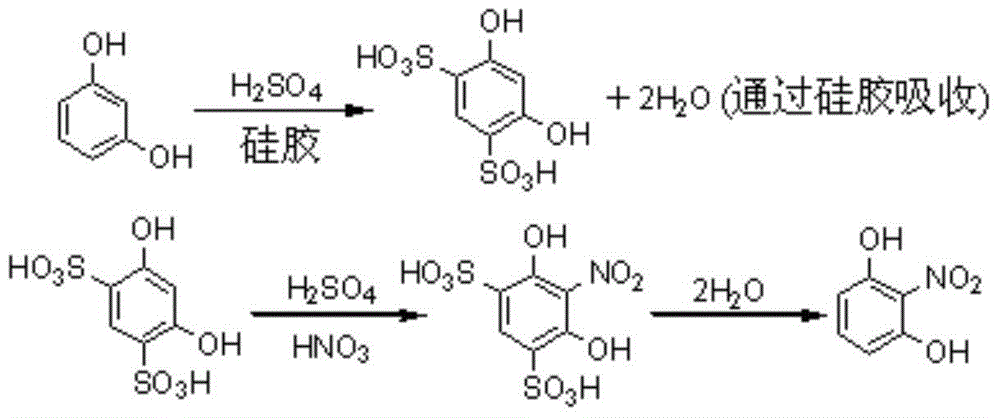

Method of synthesizing 2-nitroresorcinol by utilizing silica gel as assistant dehydrant

A technique for nitroresorcinol and resorcinol, which is applied in the field of synthesis of 2-nitroresorcinol, can solve the problems of harsh reaction conditions, increased cost, low yield and the like, and achieves mild reaction conditions, The effect of improving productivity and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Mix 1.5ml of 98% concentrated sulfuric acid with 3.0ml of 65% concentrated nitric acid, and cool the reactant to below 5°C in an ice-water bath.

[0023] Mix 5.0g resorcinol and 0.25g silica gel and put it into a 250ml three-neck round bottom flask, then slowly add 8ml98% concentrated sulfuric acid dropwise, turn on the mixer, and continue to dropwise add 17ml98% concentrated sulfuric acid while stirring. Then slowly heat to 30°C under full stirring, and keep it warm for 15 minutes, then use an ice-water bath to cool the reactant to below 5°C, then add the sulfur-nitrate mixed acid cooled in the first step, while maintaining the temperature at 5°C; After that, keep warm at 5°C for 2h, then add 20g of crushed ice and 0.1g of urea into the reactor, and continue stirring until completely dissolved. The resulting mixture was subjected to steam distillation, and the fractions on the wall of the condensation tube and in the receiving bottle were collected, cooled with ice wat...

Embodiment 2

[0025] Mix 2.5ml of 98% concentrated sulfuric acid with 5.0ml of 65% concentrated nitric acid, and cool the reactant to below 5°C in an ice-water bath.

[0026] Mix 5.0g resorcinol and 0.5g silica gel and put it into a 250ml three-neck round bottom flask, then slowly add 8ml98% concentrated sulfuric acid dropwise, turn on the mixer, and continue to dropwise add 17ml98% concentrated sulfuric acid while stirring. Then slowly heat to 60°C under full stirring, and keep it warm for 60 minutes, then use an ice-water bath to cool the reactant to below 5°C, then add the sulfur-nitrate mixed acid cooled in the first step, while maintaining the temperature at 5°C; After that, keep warm at 5°C for 3h, then add 20g of crushed ice and 0.1g of urea into the reactor, and continue stirring until completely dissolved. The resulting mixture was subjected to steam distillation, and the fractions on the wall of the condensation tube and in the receiving bottle were collected, cooled with ice wate...

Embodiment 3

[0028] Mix 3.5ml of 98% concentrated sulfuric acid with 4.0ml of 65% concentrated nitric acid, and cool the reactant to below 5°C in an ice-water bath.

[0029] Mix 5.0g resorcinol and 1.0g silica gel and put it into a 250ml three-neck round bottom flask, then slowly add 8ml98% concentrated sulfuric acid dropwise, turn on the mixer, and continue to dropwise add 17ml98% concentrated sulfuric acid while stirring. Then slowly heat to 65°C under full stirring, and keep it warm for 45 minutes, then cool the reactant to below 5°C with an ice-water bath, then add the sulfur-nitrate mixed acid cooled in the first step, while maintaining the temperature at 5°C; After that, keep warm at 5°C for 3.5h, then add 20g of crushed ice and 0.1g of urea into the reactor, and continue stirring until completely dissolved. The resulting mixture was subjected to steam distillation, and the fractions on the wall of the condensation tube and in the receiving bottle were collected, cooled with ice wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com