Preparation method of magnetic beads by extracting nucleic acid and application of method

A magnetic bead and nucleic acid technology, applied in DNA preparation, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of easy aggregation of magnetic nanoparticles, low chemical stability, and insufficient surface hydroxyl groups. Achieve the effect of simple operation, fast and thorough solid-liquid separation, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

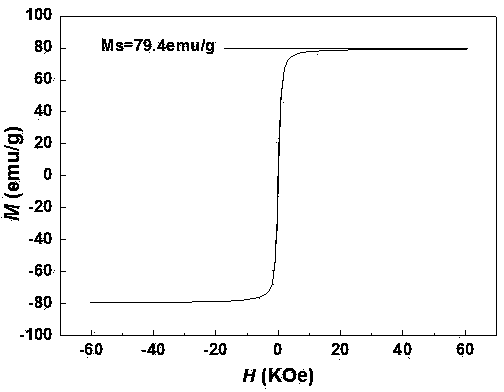

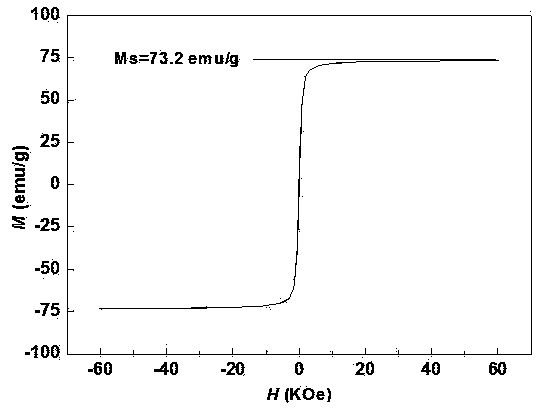

Image

Examples

Embodiment 1

[0043] A preparation method for nucleic acid extraction magnetic beads, comprising the following specific steps:

[0044] S1, Fe 3 o 4 Preparation of nanoparticles

[0045] Weigh 300g of anhydrous ferric chloride and dissolve in 1L of ultrapure water, weigh 392g of ferrous ammonium sulfate hexahydrate and dissolve in 1L of ultrapure water, transfer the two solutions into a 5L reactor and stir at 200r / min for 30min , weigh 45g of polyethylene glycol-8000, dissolve it in 400ml of ultrapure water, and transfer it to the reaction kettle; pass argon to remove oxygen for 30 minutes, adjust the reaction temperature to 60°C, adjust the speed to 500r / min, and drop 25% Ammonia water until the pH value of the system is 11, heat up to 80°C, adjust the rotation speed to 100r / min and react for 3h; The concentration was 1% ammonia water, 5% NaCl and deionized water, and the precipitate was repeatedly washed 3 times until the washing liquid was neutral, and freeze-dried at -10°C for 48 hou...

Embodiment 2

[0054] A preparation method for nucleic acid extraction magnetic beads, comprising the following specific steps:

[0055] S1, Fe 3 o 4 Preparation of nanoparticles

[0056] Same as step S1 in embodiment one;

[0057] S2, preparation of nano silicon-based magnetic beads

[0058] Take by weighing the superparamagnetic Fe obtained in the above-mentioned steps S1 3 o 4 Disperse 100 g of nanoparticles in 3L of absolute ethanol, after ultrasonic treatment for 30min, add 1L of aqueous solution with a concentration of 50 g / L trisodium citrate; after stirring at 200r / min for 30min, add ammonia water with a mass concentration of 25% to the system The pH value of the system is 10; then add dropwise 100ml of ethanol solution with a volume ratio of 50% tetraethyl orthosilicate, control the dropping rate at 0.5ml / min, and the system temperature at 30°C, and react for 4 hours after the dropping; take out the reactant , Magnetic separation of surface silicon-modified Fe 3 o 4 Nanopart...

Embodiment 3

[0060] A preparation method for nucleic acid extraction magnetic beads, comprising the following specific steps:

[0061] S1, Fe 3 o 4 Preparation of nanoparticles

[0062] Same as step S1 in embodiment one;

[0063] S2, preparation of nano silicon-based magnetic beads

[0064] Take by weighing the superparamagnetic Fe obtained in the above-mentioned steps S1 3 o 4 Disperse 500 g of nanoparticles into 4 L of absolute ethanol, and after ultrasonic treatment for 30 min, add 1 L of 50 g / L sodium edetate aqueous solution; after stirring at 200 r / min for 30 min, add 25% Ammonia water until the pH value of the system is 10; then dropwise add 130ml of ethanol solution with a volume ratio of 50% tetraethyl orthosilicate, control the dropping rate at 0.5ml / min, and the system temperature at 50°C, and react for 5 hours after the dropping; take out reactant, magnetically separates the surface silicon-modified Fe 3 o 4 Nanoparticles, after washing 3 times with absolute ethanol, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com