HA/TiO2 layer on surface of titanium alloy and preparation method thereof

A titanium alloy and bonding strength technology, which is applied to the HA/TiO2 layer on the surface of the titanium alloy and the field of its preparation, can solve the problems of low growth efficiency of hydroxyapatite and limited thickness of the hydroxyapatite layer, and meets the requirements of medical applications , The effect of increased contact area and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

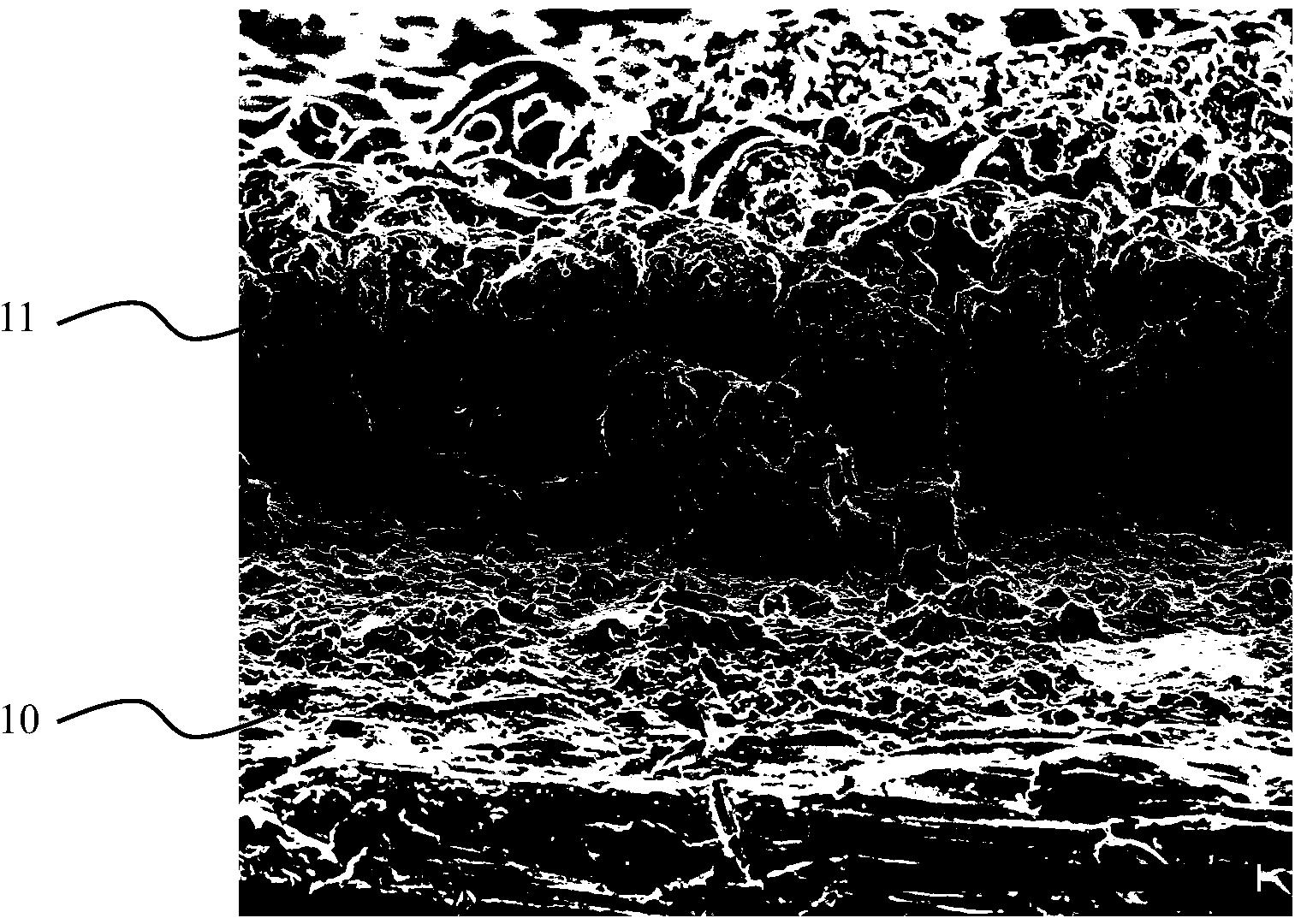

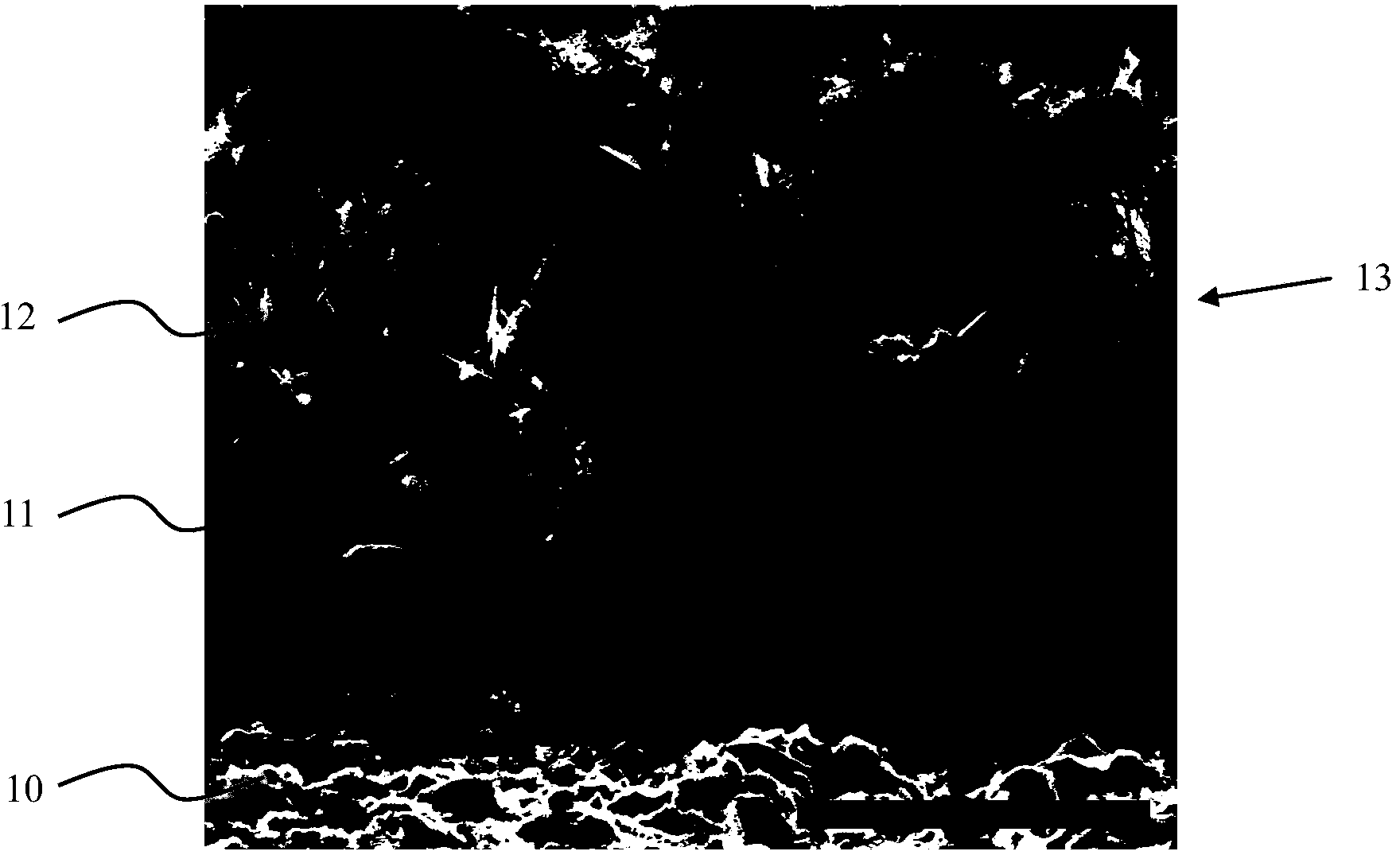

[0019] HA / TiO on the surface of titanium alloy 2 Layer preparation method one:

[0020] Step 1, configure the micro-arc oxidation treatment solution: add 1g sodium silicate, 3g calcium acetate, 2g sodium dihydrogen phosphate and 2g sodium fluoride to each liter of deionized water, stir to make it evenly mixed into a solution, add sodium hydroxide, The pH value of the above solution was adjusted to 9 to obtain a micro-arc oxidation treatment solution.

[0021] Step 2, micro-arc oxidation treatment: the chemical cost of the titanium alloy substrate used in this example is Ti-6Al-4V, the titanium alloy plate is placed in the micro-arc oxidation treatment solution obtained in step 1, as an anode, and the stainless steel tank As the cathode, micro-arc oxidation was performed in a DC pulsed micro-arc oxidation device with a current density of 2A / cm 2 , the duty cycle is 10%, and the titanium alloy plate is taken out after 10 minutes of treatment, washed with deionized water and dr...

Embodiment 2

[0030] HA / TiO on the surface of titanium alloy 2 Layer preparation method two:

[0031] Step 1, configure the micro-arc oxidation treatment solution: add 1.5g sodium silicate, 4.5g calcium acetate, 3g sodium dihydrogen phosphate and 3g sodium fluoride to each liter of deionized water, mix evenly, configure a solution, and add sodium hydroxide, and adjust the pH value of the solution to 10 to obtain a micro-arc oxidation treatment solution.

[0032] Step 2, micro-arc oxidation treatment: place the titanium alloy Ti-6Al-4V plate in the above-mentioned micro-arc oxidation treatment solution as an anode, use a stainless steel tank as a cathode, and perform micro-arc oxidation in a DC pulse micro-arc oxidation equipment, using The current density is 2.5A / cm 2 , the duty cycle was 15%, and the titanium alloy plate was taken out after 7.5 min of treatment, washed with deionized water, and then dried naturally.

[0033] The appearance of the titanium alloy plate after micro-arc oxi...

Embodiment 3

[0038] HA / TiO on the surface of titanium alloy 2 Layer preparation method three:

[0039] Step 1, configure the micro-arc oxidation treatment solution: add 2g sodium silicate, 6g calcium acetate, 4g sodium dihydrogen phosphate and 4g sodium fluoride to each liter of deionized water, mix evenly, configure a solution, and add hydroxide to the solution sodium, and adjust the pH value of the solution to 11 to obtain a micro-arc oxidation treatment solution.

[0040] Step 2, micro-arc oxidation treatment: place the titanium alloy Ti-6Al-4V plate in the above-mentioned micro-arc oxidation treatment solution as an anode, use a stainless steel tank as a cathode, and perform micro-arc oxidation in a DC pulse micro-arc oxidation equipment, using The current density is 3A / cm 2 , the duty cycle is 20%, and the titanium alloy plate is taken out after 5 minutes of treatment, cleaned with deionized water, and then dried naturally.

[0041] The morphology of the micro-arc oxidation-treated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com