Vegetable oil extraction

A technology for extracting oil and oil phase, applied in the field of palm oil, can solve problems such as difficulties, prolonged separation time, and increased wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Experiments with Indirect High Frequency Ultrasonic Treatment Using Ultrasonic Lab System

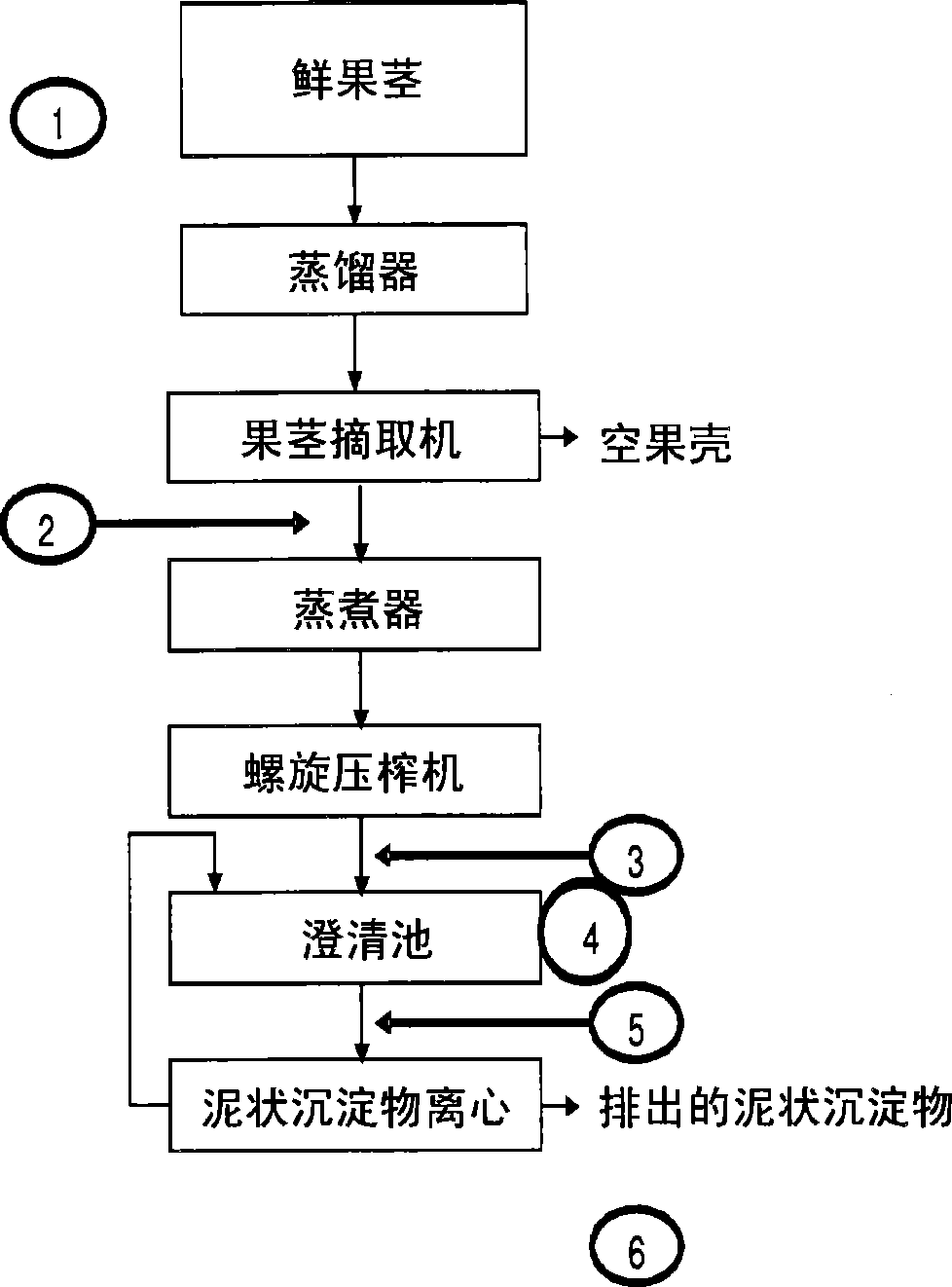

[0047] The following tests selected three intervention points to demonstrate the invention, i.e. (1) before the screw press ( figure 2 Point 3 in the middle); (2) the muddy sediment in the lower layer ( figure 2 Point 5 in ); and (3) the discharged sludge (before the sludge was centrifuged) ( figure 2 Point 6 in .

[0048] Three sonication methods were selected for processing the selected samples: Ultrasonic 1 (US1), Ultrasonic 2 (US2) and the two-step method (US1 and US2) using a long titanium rod type sonotrode or a short titanium rod sonotrode . After mixing and preheating to 70°C, the samples were pumped through an ultrasonic system. The mixture is recycled through the US1 system. In the US2 system, the transducer is placed in a water bath at 70°C and the sound waves are emitted indirectly through the wall of a plastic centrifuge tube filled with palm oil m...

Embodiment 2

[0064] Example 2: Pilot test with a plate transducer submerged in a container

[0065] Pilot tests further demonstrated other ultrasonic treatment conditions for enhanced oil extraction in various plate transducer configurations and using single frequency or combinations of multiple frequencies. Ultrasonic waves are applied to the feed before the screw press ( figure 2 Point 3 in): Ultrasonic 3 (US3), Ultrasonic 4 (US4), and Ultrasonic 5 (US5); Figure 6 the respective configurations in a, b and c). Fresh samples were obtained directly from the factory's processing line at 85°C and processed directly in the ultrasonic vessels used for each configuration. In all cases, the transducers were placed vertically or horizontally inside the container and emitted sound waves directly into the palm oil material.

[0066] US3 uses a frequency of 400kHz and a power of 222-227dB, utilizing vertical plate transducers arranged vertically on two different planes;

[0067] US4 uses freque...

Embodiment 3

[0074]Embodiment 3: Utilize the pilot test that the transducer that is installed on the outside of container carries out (active surface directly contacts with sample)

[0075] Additional pilot tests demonstrated that high frequencies are effective in enhancing oil extraction when using transducers mounted externally on prefabricated windows (or openings) through the vessel wall. This prototype ( Figure 10 ) has the advantage that only the active area of the transducer is in direct contact with the sample, thus reducing the thermal load on the transducer and increasing its lifetime. Figure 10 The pilot systems in a and 10b are designed to accommodate 600 kHz and 400 kHz transducers, respectively. The system components are numbered and indicated as follows: (1) Spare cutout cover, (2) Support clamping bars, (3) Mounting screws, (4) Cutout support frame, (5) Transducer cooling (6) transducer signal port, (7) 600kHz plate transducer, (8) side window, (9) removable cover, (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com