A kind of oil cooler for high-power high-voltage electric vacuum device

A technology for vacuum devices and oil coolers, applied in electrical components, circuits, discharge lamps, etc., can solve the problems of the insulation distance making the structure difficult to compact, the insulation and heat dissipation effects are large, and the air heat conduction efficiency is low, so as to overcome the air cooling method. Insufficient, stable dielectric strength, stable and reliable device operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

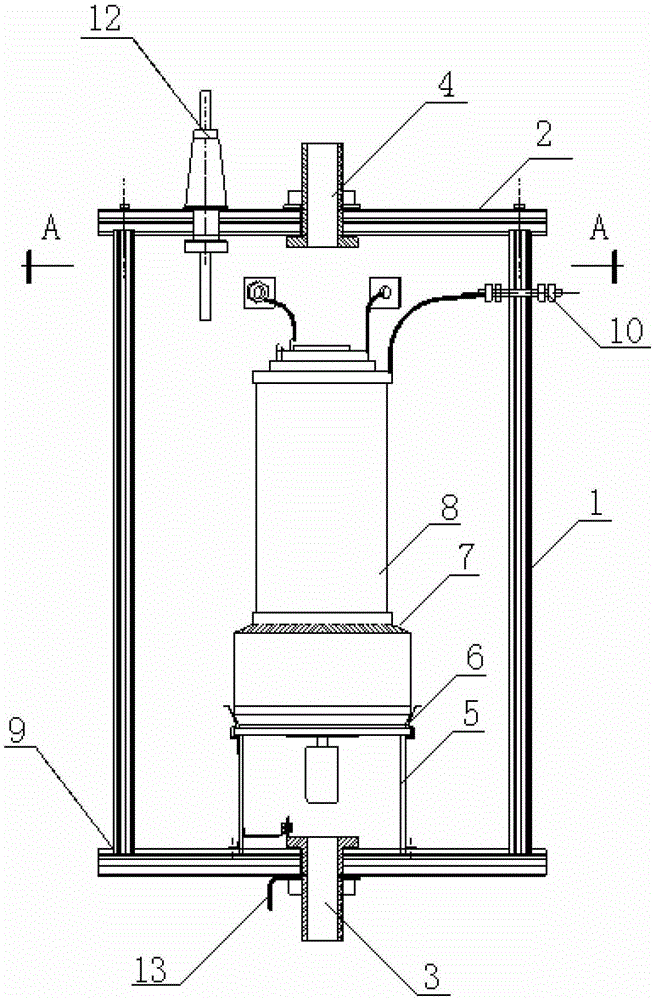

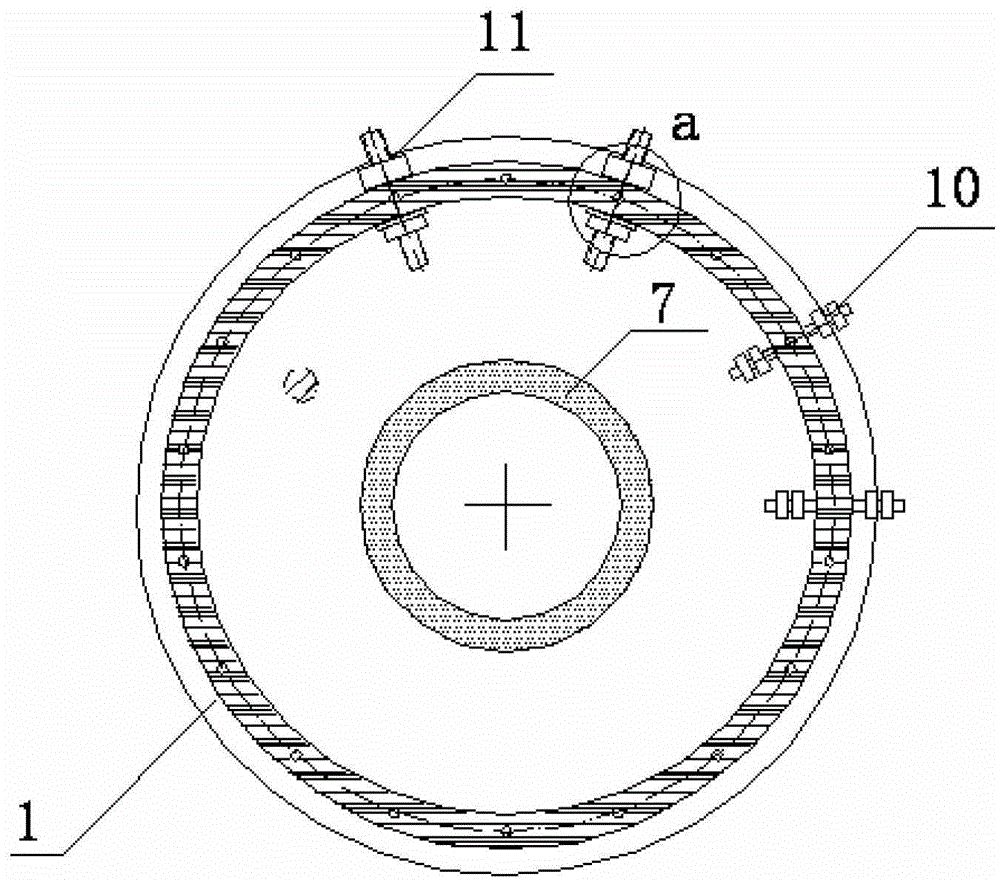

[0020] An oil cooler for high-power high-voltage electric vacuum devices such as figure 1 , figure 2 As shown, it is assembled by the following steps:

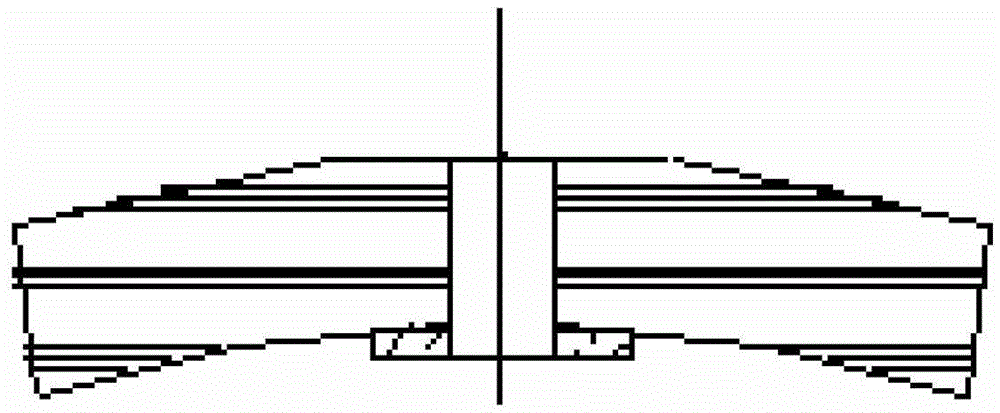

[0021] 1. First process the custom-made plexiglass or epoxy resin tube or plate into a blank, and the above two materials have been used in the device; then machine them into parts of the outer barrel of the oil cooler, including the side wall 1 , the base plate 9 and the cover plate 2, the base plate 9 and the cover plate 2 all have side wall grooves fixed with the side wall 1, and are respectively provided with holes for setting the oil inlet 3 and the oil outlet 4, and the holes are sealed with The oil inlet 3 and the oil outlet 4; the end of the side wall 1 is tapped, and the center line of the above holes coincides, and the screw connection can be used to compress and seal, similar to the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com