Nylon moisture retardant and preparation method of nylon moisture retardant

A nylon and wet agent technology, applied in the field of plastic additives, can solve the problems of reduced 24h water absorption, complex preparation process and high cost, and achieve the effects of easy mass production, simple process and reduced water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

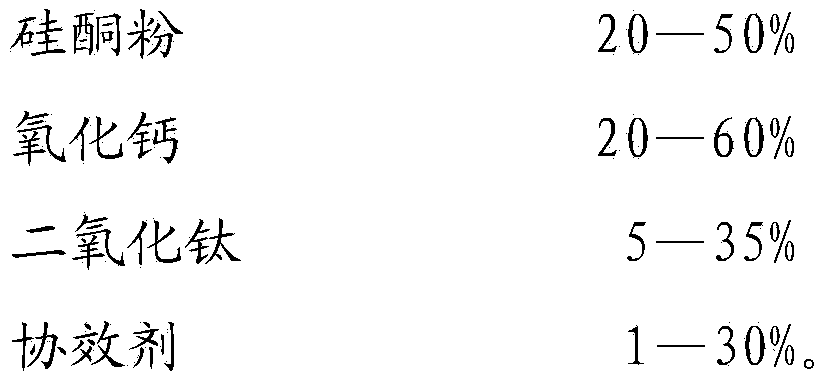

Method used

Image

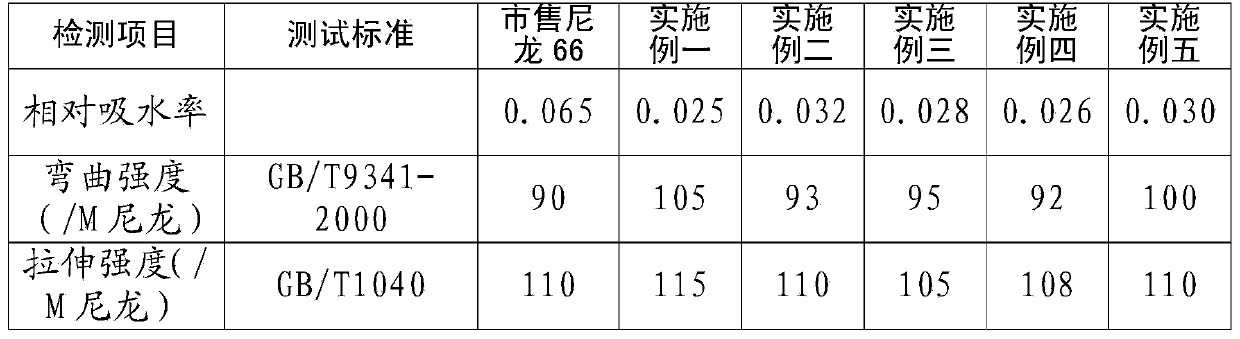

Examples

Embodiment 1

[0022] Embodiment 1: A nylon anti-humidity agent, weighed according to mass percentage: 40% of silicone powder, 40% of calcium oxide, 10% of titanium dioxide, and 10% of synergist. The preparation method is to add the above raw materials into a high-speed mixer, Insulated and stirred at room temperature for 15 minutes, and discharged to obtain plastic additives.

[0023] The nylon anti-humidity agent is used as a plastic additive to modify the nylon matrix, and the addition amount is 3% of the mass of the nylon matrix.

Embodiment 2

[0024] Embodiment 2: A nylon anti-humidity agent, weighed according to mass percentage: 30% of silicone powder, 20% of calcium oxide, 35% of titanium dioxide, 15% of synergist, its preparation method is to add the above raw materials into a high-speed mixer, Insulated and stirred at room temperature for 20 minutes, and discharged to obtain plastic additives.

[0025] The nylon anti-humidity agent is used as a plastic additive to modify the nylon matrix, and the addition amount is 1% of the mass of the nylon matrix.

Embodiment 3

[0026] Embodiment 3: A nylon anti-humidity agent, weighed according to mass percentage: 50% of silicone powder, 40% of calcium oxide, 5% of titanium dioxide, 5% of synergist, and its preparation method is to add the above raw materials into a high-speed mixer, Insulated and stirred at room temperature for 18 minutes, and discharged to obtain plastic additives.

[0027] The nylon anti-humidity agent is used as a plastic additive to modify the nylon matrix, and the addition amount is 5% of the mass of the nylon matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com