Rectangular-hole single-stage diffraction grating

A single-stage diffraction and diffraction grating technology, which is applied in the field of diffraction gratings, can solve the problems of spectral photon sieves and quantum lattice gratings that cannot be self-supported, self-supported, and interfered, so as to improve advanced diffraction pollution and facilitate practical use. Promote the application, improve the effect of purity and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

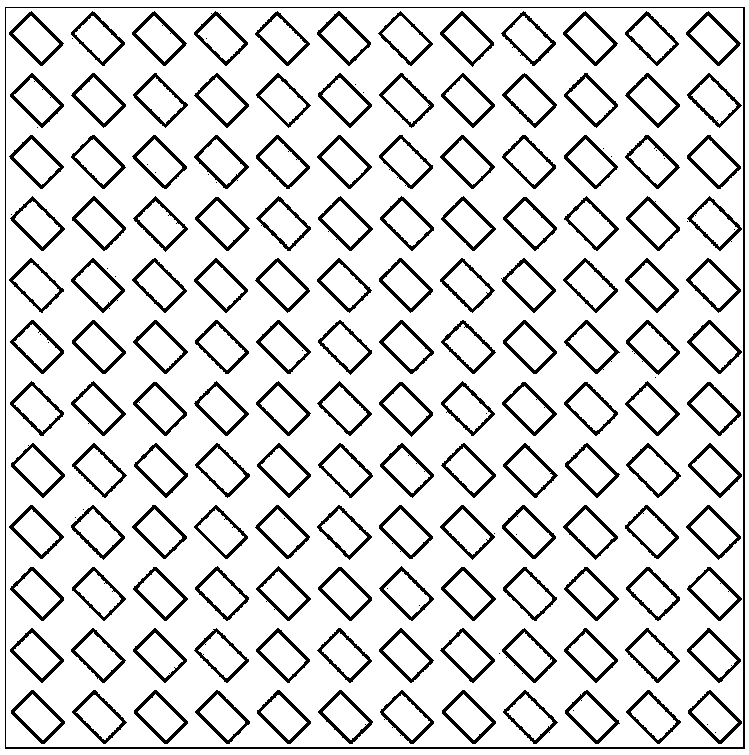

[0032] Fabrication of Single-stage Diffraction Grating with Rectangular Aperture in X-ray Band

[0033] The preparation process of the 1000 lines / mm transmissive planar rectangular-hole single-stage diffraction grating suitable for the soft X-ray band is described below in conjunction with the accompanying drawings, as well as the computer simulation results of the diffraction effect of the rectangular-hole single-stage diffraction grating of the present invention and its comparison with ordinary gratings. Comparison of diffraction effects.

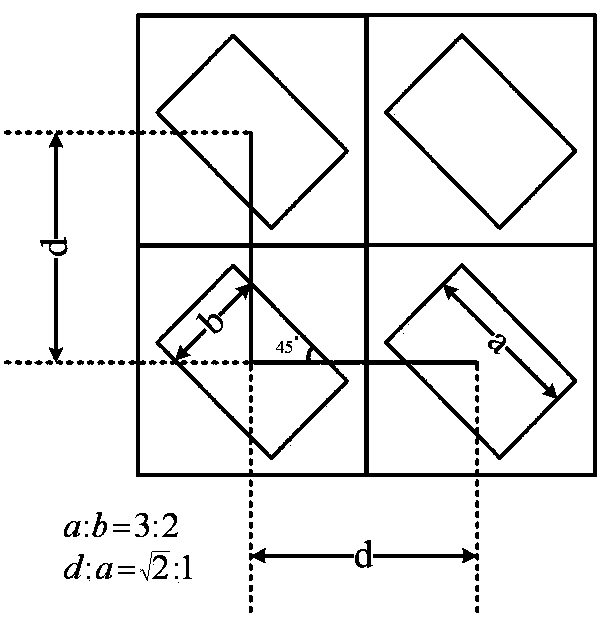

[0034] a: Determine the size of the raster primitive

[0035] The wavelength of soft X-rays is several nanometers to tens of nanometers, so the grating constant d=1um is selected, and the grating line density is 1000 lines / mm, then the length of the transmission rectangular hole element is =707nm, wide =471nm;

[0036] b: will be as figure 1 The grating of the shown structure is converted into a LEDIT format file according to the...

Embodiment 2

[0044] Fabrication of Replicated Gratings by X-ray Lithography

[0045] a: same as step c in Example 1;

[0046] b: use the mask produced in Example 1 as the original exposure image, and perform X-ray exposure on the film produced in step a of this example;

[0047] c: same as step e in embodiment 1;

[0048]d: Removing the photoresist to obtain a single-stage diffraction grating replication grating with a radial planar rectangular hole.

Embodiment 3

[0050] Fabrication of the reflective grating

[0051] a: By means of transfer printing, using the same silicon wafer, gold film and photoresist material as in Example 1 or Example 2, adding a layer of light-transmitting substrate under the gold film as a support, making the same silicon wafer as in Example 1 or Example 2 The reverse pattern structure of embodiment 2 can be made into a reflective grating of a transmissive plane rectangular hole single-stage diffraction grating, and the diffraction pattern of the reflective grating is the same as that of embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com