Self-supporting flexible super capacitor electrode material and preparation method

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of reduced electrochemical performance of supercapacitors, shape limitations of electrode devices, etc., so as to save the electrode preparation process and improve The effect of specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

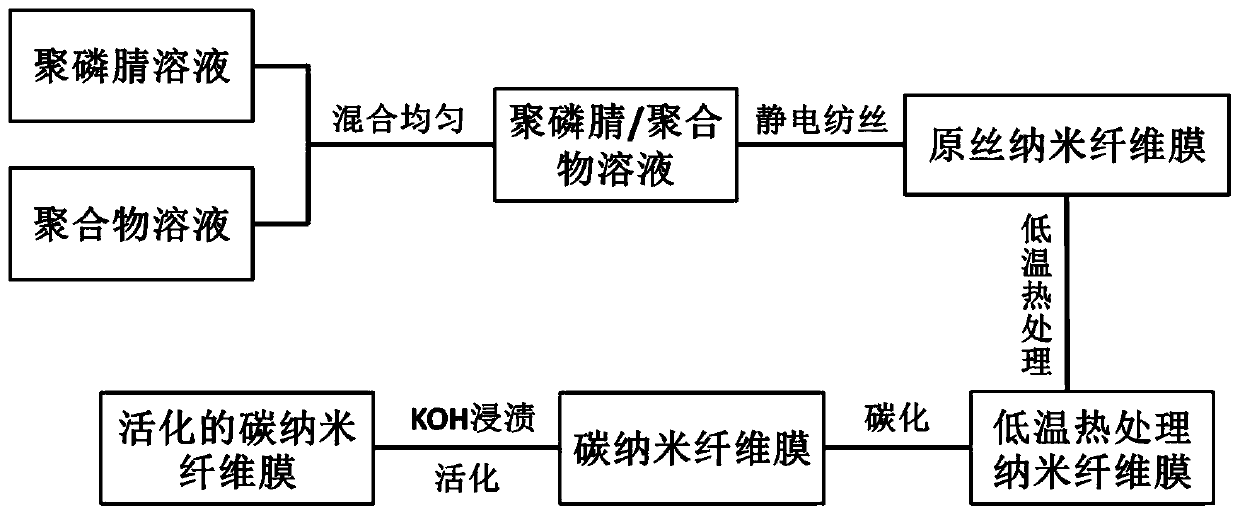

[0041] 0.1305g of phenoxy polyphosphazene (PDPP) was dissolved in 10ml of N, N-dimethylformamide, added to 20ml of polyamic acid (PAA) solution with a solid content of 15%, stirred for 12h to obtain a uniform PAA / PDPP solution, wherein the weight ratio of PDPP and PAA is 3.9:100.

[0042] Pour the uniform PAA / PDPP solution into the syringe, and prepare the PAA / PDPP nanofiber membrane by electrospinning. 18kV. Then, the PAA / PDPP nanofiber membrane was heat-treated in an oven with programmed temperature increase, and the heat treatment was performed at 300° C. for 2 hours to obtain a low-temperature heat-treated nanofiber membrane.

[0043] The low-temperature heat-treated nanofiber membrane was placed in a tube furnace, treated in a nitrogen atmosphere at 800°C for 2 hours, the heating rate was 2.5°C / min, and the cooling rate was 5°C / min to obtain a carbonized nanofiber membrane.

[0044] The carbonized nanofiber membrane was immersed in a 5M KOH solution for 0.5 hour, and dr...

Embodiment 2

[0048] 0.2141g of phenoxy polyphosphazene (PDPP) was dissolved in 10ml of N, N-dimethylformamide, added to 20ml of polyamic acid (PAA) solution with a solid content of 15%, stirred for 12h to obtain a uniform PAA / PDPP solution, wherein the weight ratio of PDPP and PAA is 6.4%.

[0049] Pour the uniform PAA / PDPP solution into the syringe, and prepare the PAA / PDPP nanofiber membrane by electrospinning. 18kV. Then, the PAA / PDPP nanofiber membrane was heat-treated in an oven with programmed temperature increase, and the heat treatment was performed at 300° C. for 2 hours to obtain a low-temperature heat-treated nanofiber membrane.

[0050] The low-temperature heat-treated nanofiber membrane was placed in a tube furnace, treated in a nitrogen atmosphere at 800°C for 2 hours, the heating rate was 2.5°C / min, and the cooling rate was 5°C / min to obtain a carbonized nanofiber membrane.

[0051] The carbonized nanofiber membrane was immersed in a 5M KOH solution for 0.5 hour, and dried...

Embodiment 3

[0055] 0.3446g of phenoxy polyphosphazene (PDPP) was dissolved in 10ml of N, N-dimethylformamide, added to 20ml of polyamic acid (PAA) solution with a solid content of 15%, stirred for 12h to obtain a uniform PAA / PDPP solution, wherein the weight ratio of PDPP and PAA is 10.3:100.

[0056] Pour the uniform PAA / PDPP solution into the syringe, and prepare the PAA / PDPP nanofiber membrane by electrospinning. 18kV. Then, the PAA / PDPP nanofiber membrane was heat-treated in an oven with programmed temperature increase, and the heat treatment was performed at 300° C. for 2 hours to obtain a low-temperature heat-treated nanofiber membrane.

[0057] The low-temperature heat-treated nanofiber membrane was placed in a tube furnace, and treated in a nitrogen atmosphere at 800°C for 2 hours, with a heating rate of 2.5°C / min and a cooling rate of 5°C / min to obtain a carbonized nanofiber membrane.

[0058] The carbonized nanofiber membrane was immersed in a 5M KOH solution for 0.5 hour, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com