Single-welding bend pressing and molding method

A press forming and elbow technology, which is applied in the field of press forming, can solve the problems of complicated process and waste of energy, and achieve the effects of simple process, reduced product cost and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

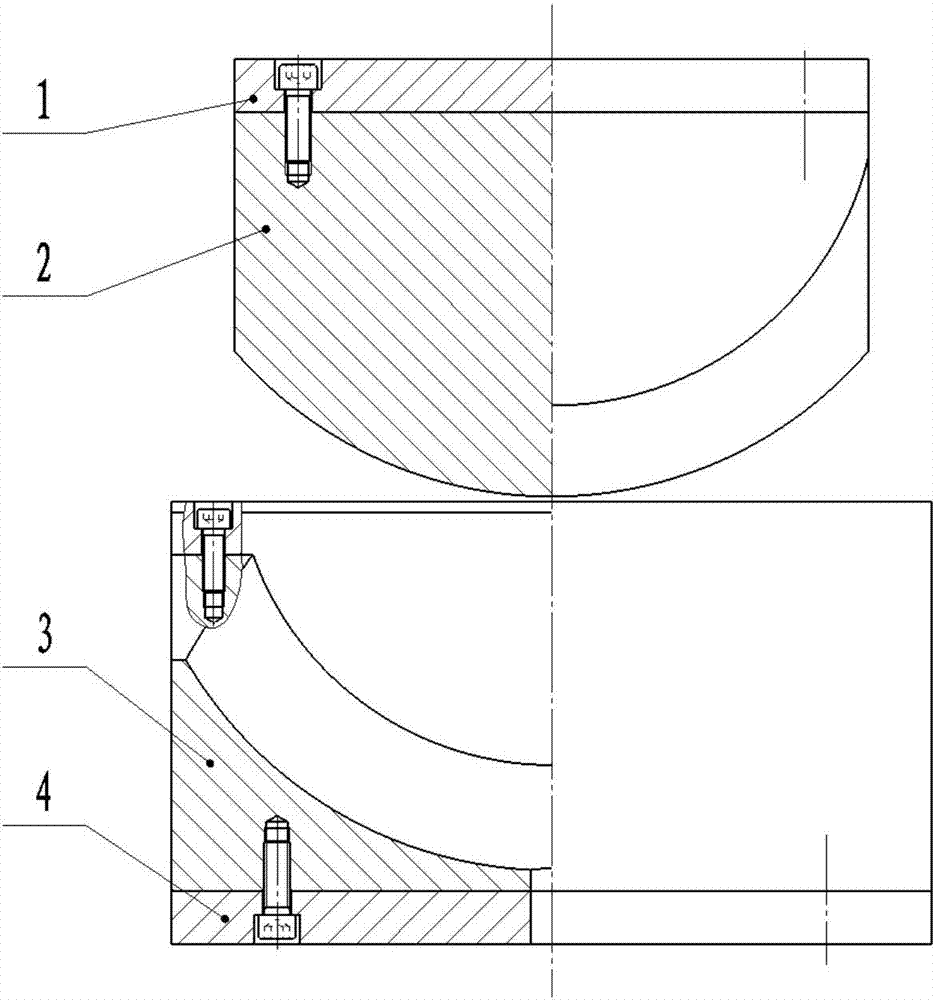

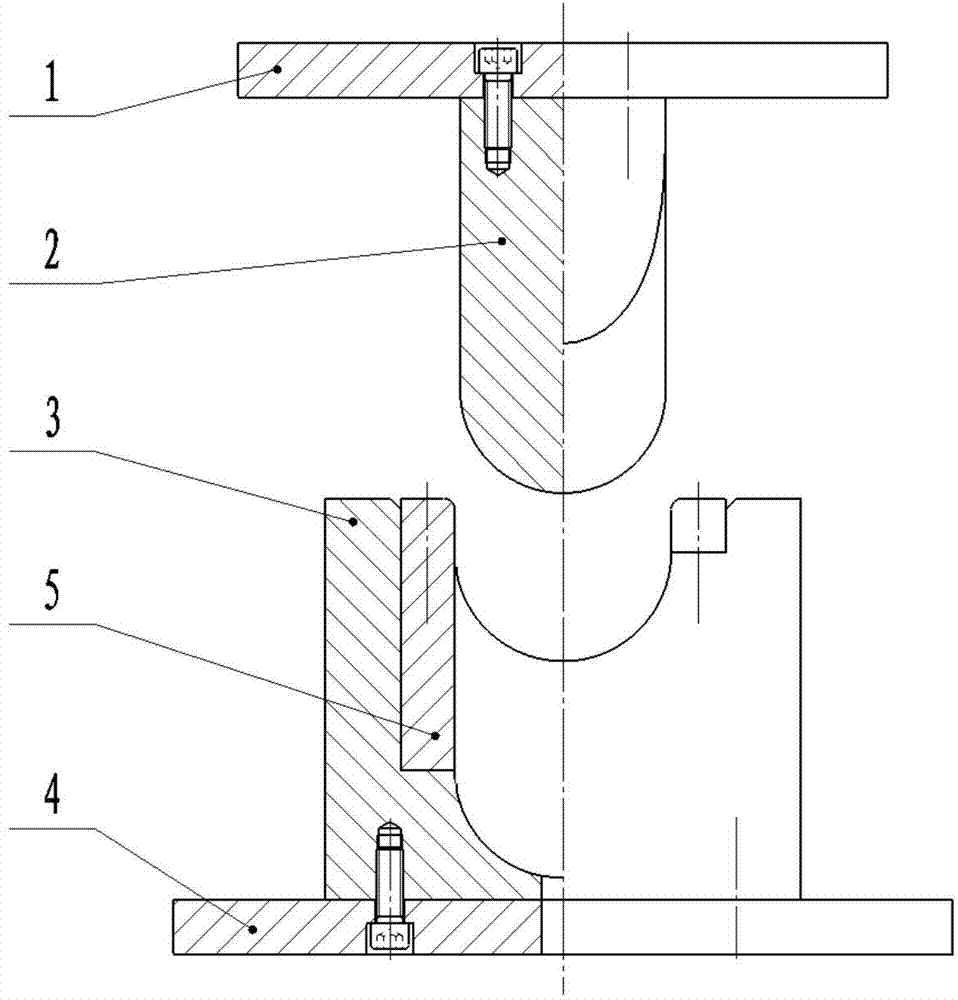

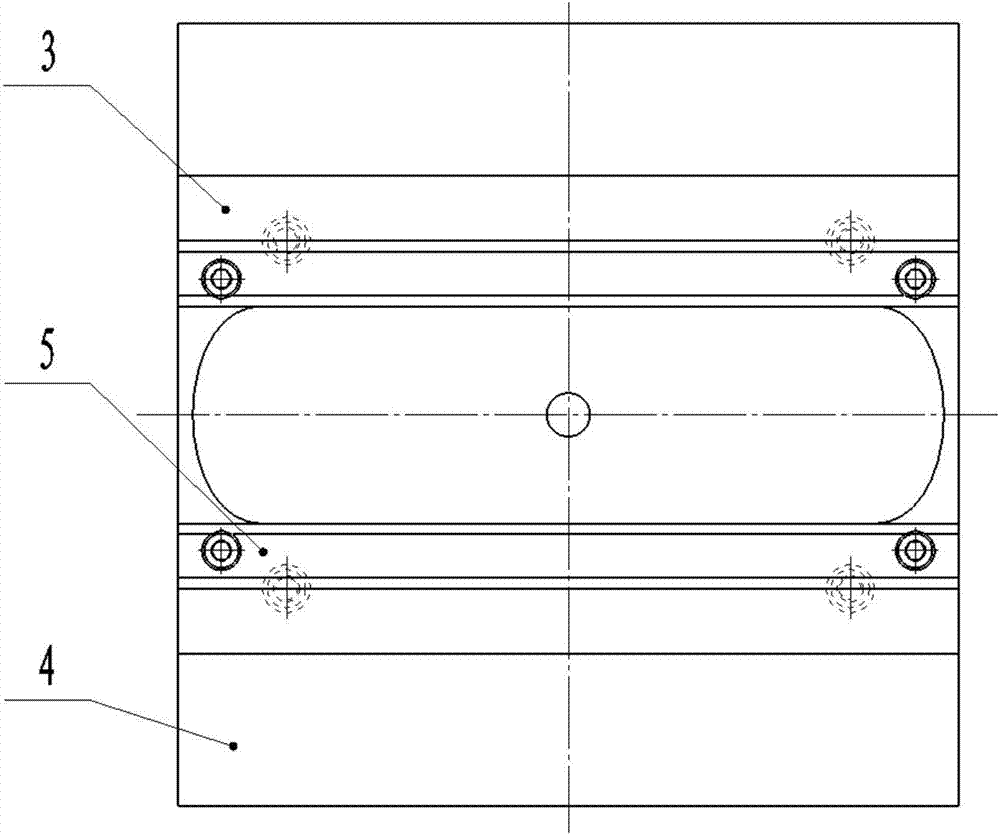

[0041] The present invention is described by taking a 90-degree elbow of production material Q235, wall thickness t=2.5mm, nominal diameter D=100mm, and bending radius 1.25D=125mm as an example.

[0042] Select a Q235 plate with a thickness of 2.5mm as the raw material, and the shape and size of the blank 7 are calculated by the Dynaform software plate size (such as Figure 7 shown), and cut with a cutting machine. Install the finished blank on the machine tool, and process the groove required by the cross-section on both sides of the blank through the relative movement of the tool and the blank (such as Figure 8 Shown), the groove is a Y-shaped groove, and the size is 1×1.5mm. Place the blank on the die with the groove facing down, and position it through the positioning pins so that the centerline of the blank is aligned with the centerline of the die (such as Figure 9 shown). The die is fixed on the workbench of the press, and the punch I is installed on the slider of ...

Embodiment 2

[0044] The present invention will be described by taking a 90-degree elbow with production material X80, wall thickness t=30mm, nominal diameter D=1200mm, and bending radius 1.5D=1800mm as an example.

[0045] The thickness is 30mm X80 plate is selected as the raw material, the shape and size of the blank is calculated by the Dynaform software plate size, and the material is cut with a cutting machine. The finished blank is clamped on the machine tool, and the groove required by the cross section on both sides of the blank is processed through the relative movement of the tool and the blank. The groove is a Y-shaped groove with a size of 12×18mm. Place the blank on the die with the groove facing down, and position it through the positioning pins so that the centerline of the blank is aligned with the centerline of the die. The die is fixed on the workbench of the press, and the punch I is installed on the slider of the press, and the slider drives the punch I to press down to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com