Heat proof vacuum tube

A vacuum tube and vacuum chamber technology, which is applied in the directions of heat preservation, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of high operating cost, difficult manufacturing, complex structure, etc., and achieve the effects of low cost, convenient transportation and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

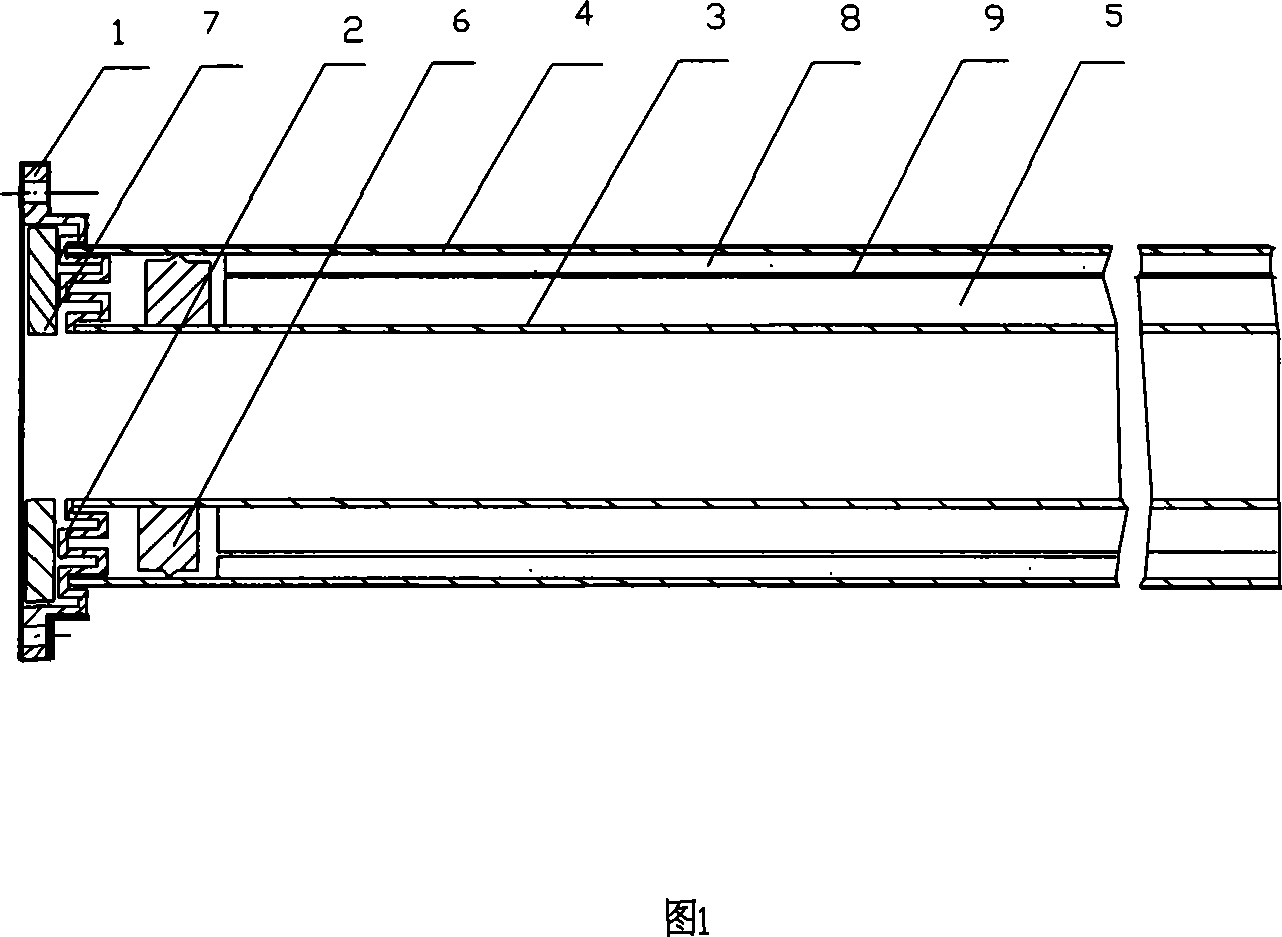

[0011] Embodiment 1: As shown in Figure 1 and Figure 3, the heat-insulating vacuum tube includes a flange 1, a pipe body 3, and a casing 4, and among the flanges 1 at both ends of the heat-insulating vacuum tube, at least one flange 1 is provided with a stainless steel The continuous corrugated knot 2 forms a vacuum chamber 5 with the steel pipe body 3 and the steel casing 4. The steel pipe body 3 is equipped with a number of axial or radial continuous or discontinuous plastic support ribs, support rings, or support points 6, Supported on the inner wall of the steel casing 4.

Embodiment 2

[0012] Embodiment 2: As shown in FIG. 1 , it is basically the same as Embodiment 1, except that the flange 1 has continuous corrugated knots 2 and is matched with a rubber elastic washer 7 .

Embodiment 3

[0013] Embodiment 3: As shown in Figure 1, it is basically the same as Embodiment 1, the difference is that a foam insulation material 8 is placed in the vacuum chamber 5, and a metal foil film 9 is sprayed on the insulation material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com