Carbon dioxide solid absorbent as well as preparation method thereof

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, through absorption, separation methods, etc., can solve the problems of low absorbent recycling rate, fast absorbent deterioration speed, and high regeneration energy consumption, achieving low cost, porosity, etc. Excellent structure and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention is a carbon dioxide solid absorber, which comprises a composite carrier composed of activated carbon and zirconium dioxide. The surface of the composite carrier is loaded with ionic liquid polymer (polyionic liquid), and the surface of the activated carbon is loaded with zirconium dioxide. The ionic liquid polymer is chlorovinylbutylimidazolium ionic liquid polymer. The composite support is based on the precursor of zirconium oxychloride and H 2 o 2 It is prepared by adding activated carbon during the reaction process of preparing zirconia sol as a hydrolysis agent. The composite carrier prepared by the method has a good pore structure, is more suitable as an absorbent carrier, and the cost of the zirconium oxychloride is relatively low, which is beneficial to reducing the use cost.

[0036] The mass ratio of the ionic liquid polymer (polyionic liquid) to the composite carrier is 1:9-1:1, and the most preferred mass ratio is 1:6-1:1.5. The mass ratio of...

Embodiment 2

[0049] The invention is a carbon dioxide solid absorber, which comprises a composite carrier composed of activated carbon and zirconium dioxide. The surface of the composite carrier is loaded with ionic liquid polymer (polyionic liquid), and the surface of the activated carbon is loaded with zirconium dioxide. The ionic liquid polymer is bromovinylbutylimidazolium ionic liquid polymer. The composite carrier is prepared by adding activated carbon during the reaction process of preparing zirconium dioxide sol with zirconium oxychloride as the precursor and H2O2 as the hydrolysis agent. The composite carrier prepared by the method has a good pore structure, is more suitable as an absorbent carrier, and the cost of the zirconium oxychloride is relatively low, which is beneficial to reducing the use cost.

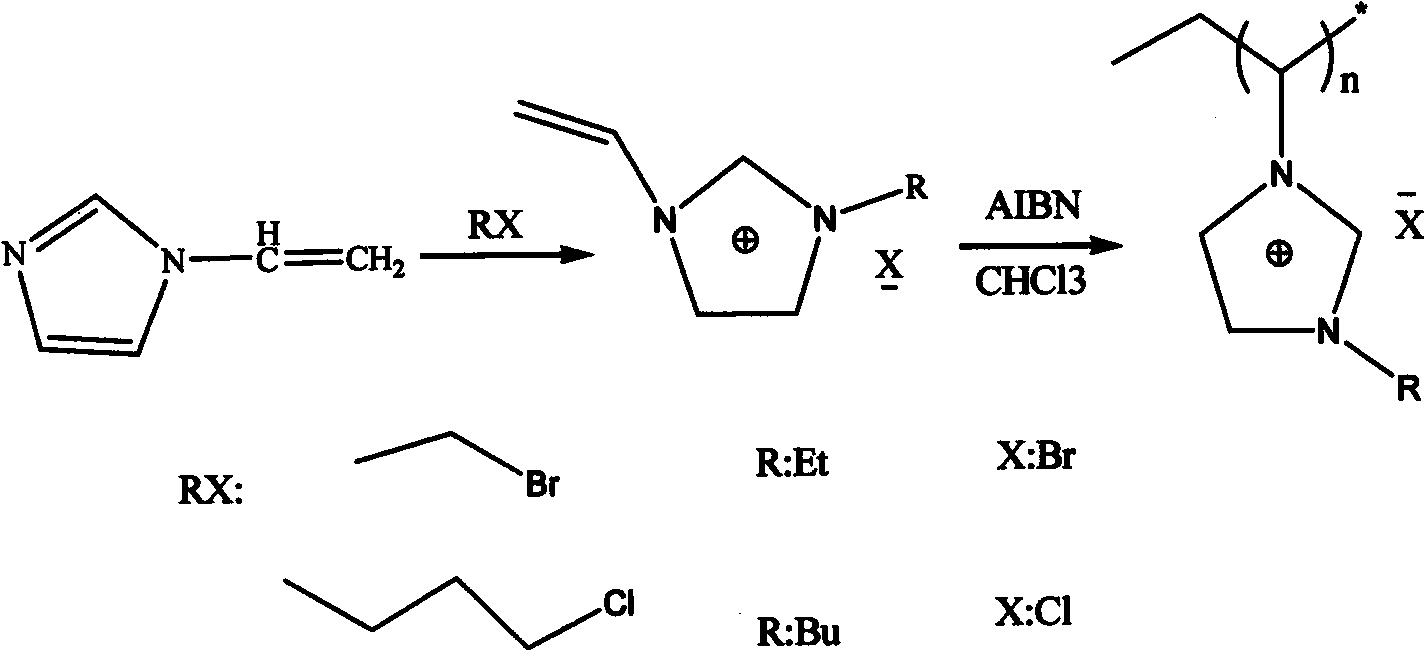

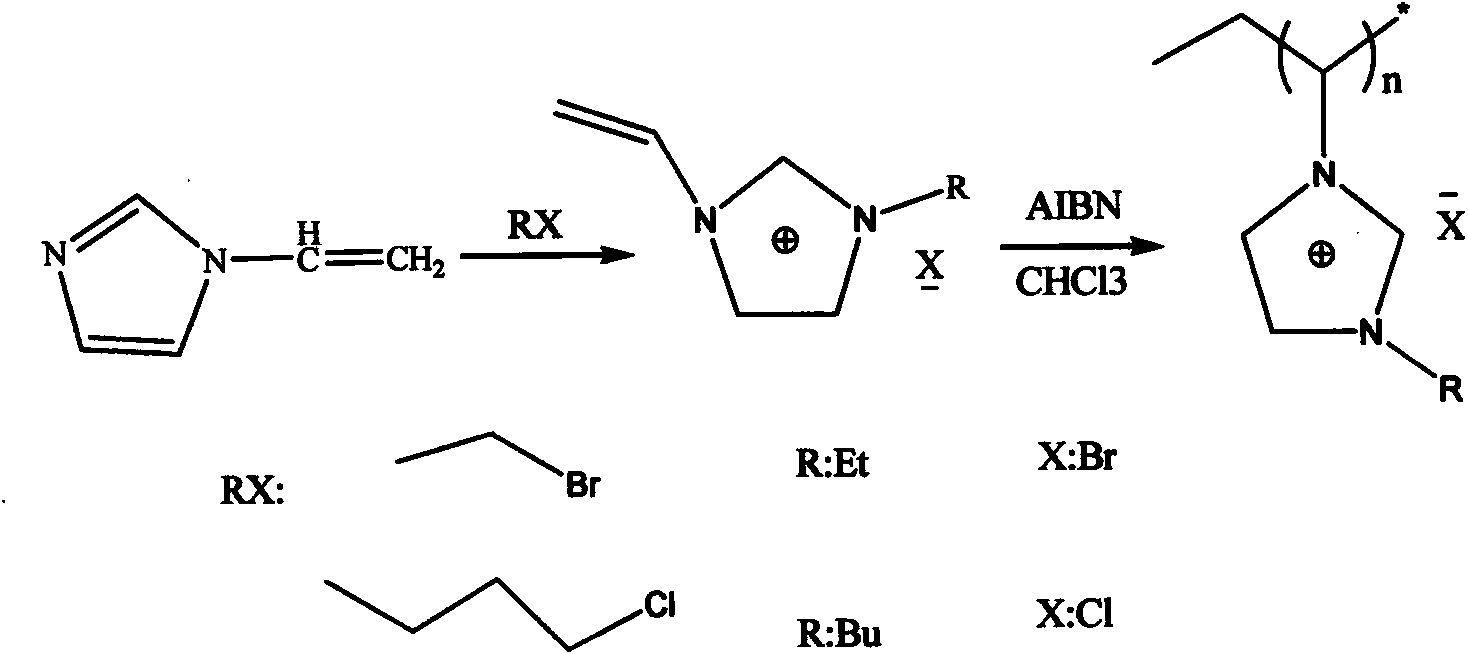

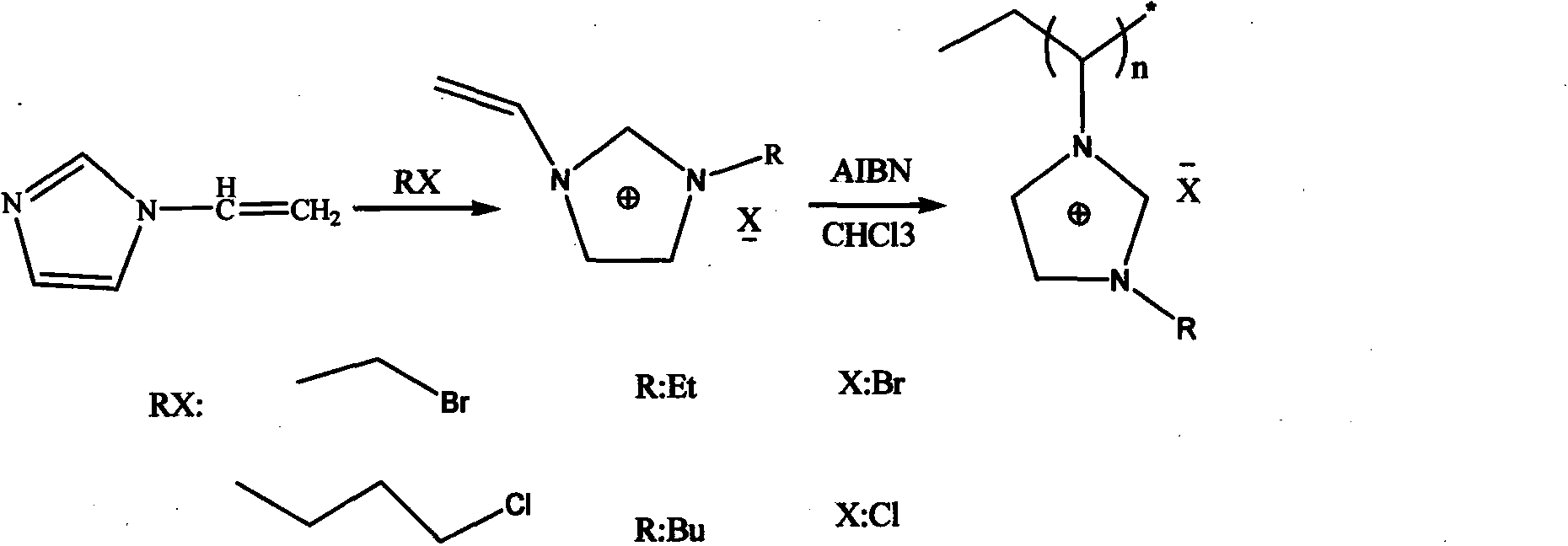

[0050] Chlorine (bromo) vinyl butyl imidazole polyionic liquid preparation method is as follows:

[0051]

[0052] The preparation steps of the ionic liquid polymer of bromo...

Embodiment 3

[0062] The invention is a carbon dioxide solid absorber, which comprises a composite carrier composed of activated carbon and zirconium dioxide. The surface of the composite carrier is loaded with ionic liquid polymer (polyionic liquid), and the surface of the activated carbon is loaded with zirconium dioxide. The ionic liquid polymer is chlorovinylbutylimidazolium ionic liquid polymer. The composite carrier is prepared by adding activated carbon during the reaction process of preparing zirconium dioxide sol with zirconium oxychloride as the precursor and H2O2 as the hydrolysis agent. The composite carrier prepared by the method has a good pore structure, is more suitable as an absorbent carrier, and the cost of the zirconium oxychloride is relatively low, which is beneficial to reducing the use cost.

[0063] Chlorine (bromo) vinyl butyl imidazole polyionic liquid preparation method is as follows:

[0064]

[0065] The preparation steps of the ionic liquid polymer of chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com