A 18o on-line labeled protein quantitative analysis platform and its operation method

A quantitative analysis and operation method technology, applied to the 18O online labeling protein quantitative analysis platform and its operation field, can solve the problems of low labeling efficiency, cumbersome operation and time-consuming, etc., and achieve high labeling time, improved analysis throughput, and pretreatment The effect of step reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

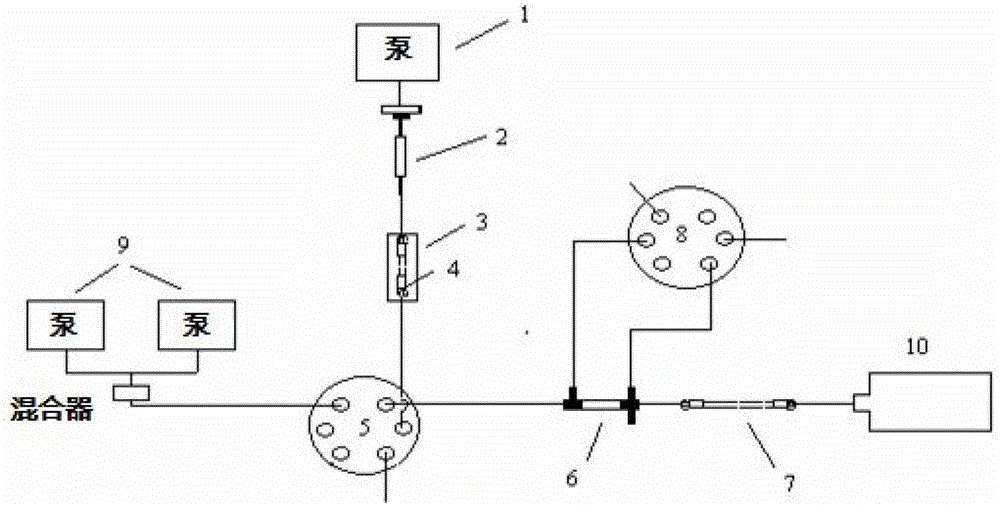

[0026] Such as figure 1 As shown, the analysis device consists of a syringe pump 1, a sampling needle 2, a column thermostat 3, an enzyme reactor 4, a first four-way or six-way valve 5, a peptide trapping column 6, a polypeptide separation column 7, a second It consists of a four-way or six-way valve 8, a liquid chromatography pump 9, and a mass spectrometer detector 10. The analysis device is characterized in that the protein is enzymatically hydrolyzed, 18 O mark, integration of peptide separation system. The operation is as follows: adjust the flow rate through the syringe pump 1, inject the protein sample in the injection needle 2 into the enzyme reactor 4 (the enzyme reactor 4 is placed in the column oven 3), and after incubation for 1 hour, the enzyme The peptide segment after enzymolysis in the reactor 4 is injected onto the trapping column 6 through the first four-way or six-way valve 5, and the first four-way or six-way valve 5 and the second four-way or six-way val...

Embodiment 2

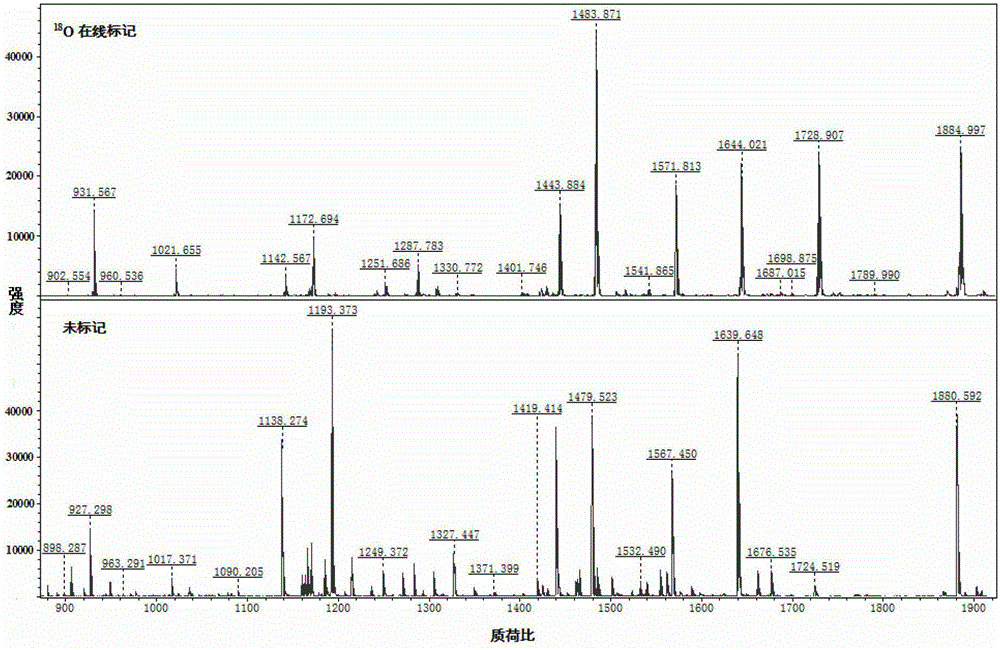

[0028] use 18 O online labeling method for analysis of bovine serum albumin. 0.1mg / mL bovine serum albumin solution (dissolved in H 2 16 O 50mM NH 4 HCO 3 Middle) Load the sample onto the enzyme column and incubate for one hour. After incubation, use H 2 16 O 50mM NH 4 HCO 3 Samples were eluted and analyzed using MALDI-TOF; similarly, 0.1 mg / mL bovine serum albumin solution (dissolved in H 2 18 O 50mM NH 4 HCO 3 Middle) Load the sample onto the enzyme column and incubate for one hour. After incubation, use H 2 18 O 50mM NH 4 HCO 3 Samples were eluted and analyzed using MALDI-TOF. The MALDI-TOF analysis results of the two samples are as follows figure 2 shown.

Embodiment 3

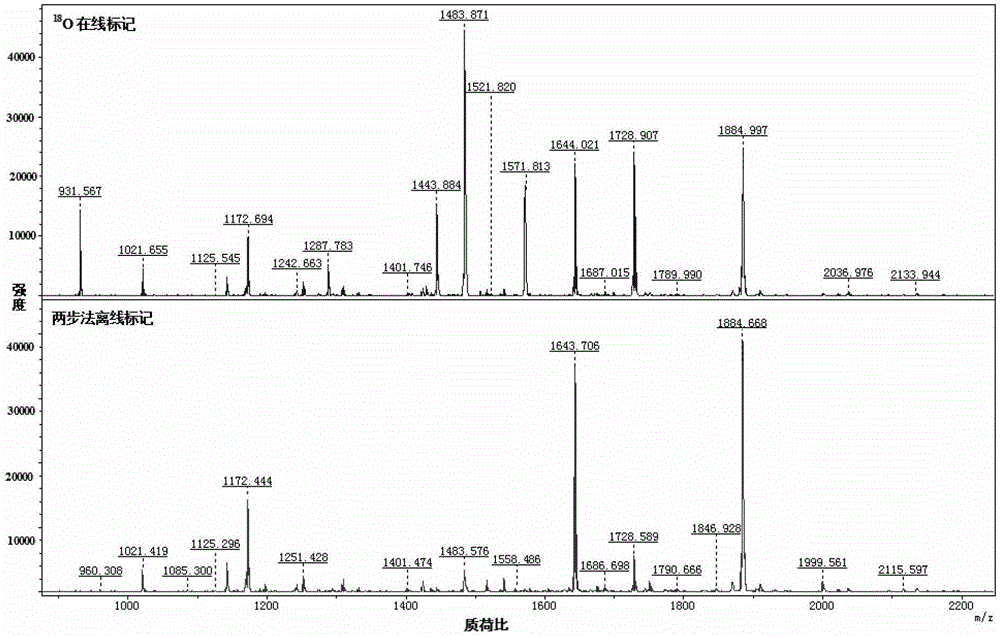

[0030] adopt respectively18 O online labeling and two-step method reported in the literature for the analysis of bovine serum albumin. 0.1mg / mL bovine serum albumin solution (dissolved in H 2 18 O 50mM NH 4 HCO 3 Middle) Load the sample onto the enzyme column and incubate for one hour. After incubation, use H 2 18 O 50mM NH 4 HCO 3 The samples were eluted and analyzed using MALDI-TOF 18 O labeling efficiency; to another 0.1mg / mL bovine serum albumin solution (dissolved in H 2 16 O 50mM NH 4 HCO 3 (Middle) was added trypsin (the ratio of trypsin to protein was 1:25) for enzymolysis overnight, and then the enzymolysis solution was desalted and evaporated to dryness, and the evaporated sample was redissolved in H 2 18 O 50mM NH 4 HCO 3 (containing 20% acetonitrile by volume), then add trypsin (the ratio of trypsin to protein is 1:25) and incubate for 24 hours, and finally use MALDI-TOF to 18 The labeling efficiency of O was analyzed. Two methods for bovine serum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com