A method for preparing a hole-inducing cigarette paper that can reduce the release of harmful substances such as CO in mainstream smoke of cigarettes

A technology for cigarette mainstream smoke and harmful substances, applied in special paper, paper, papermaking, etc., can solve problems that affect cigarette smoking and are not suitable for industrial production, and achieve the effect of improving quality and reducing CO emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

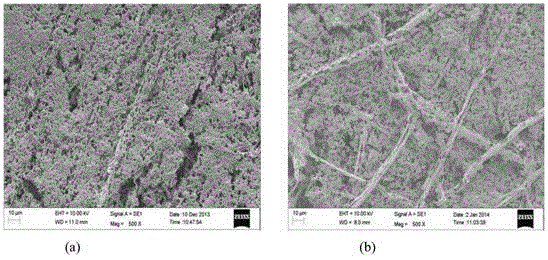

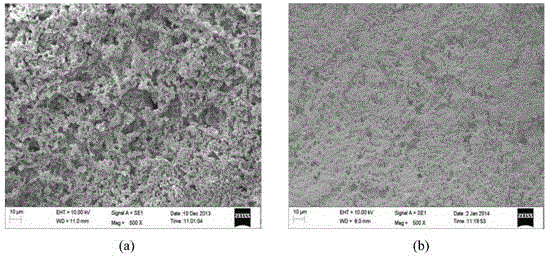

Image

Examples

Embodiment 2

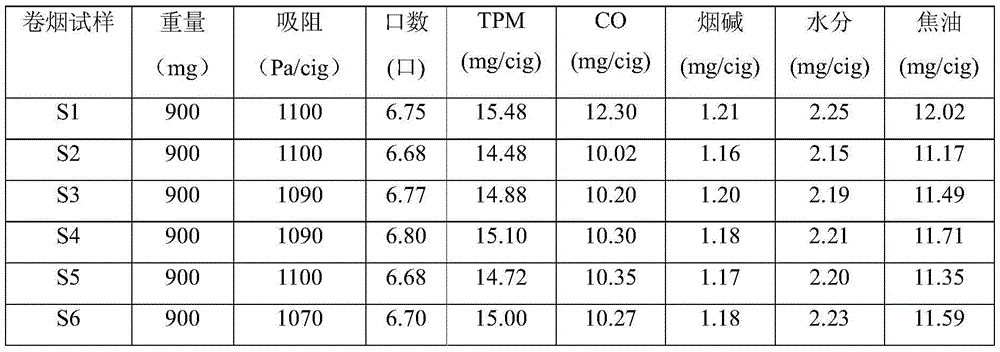

[0033] Take 150 kg of softwood pulp and 420 kg of birch hardwood pulp, add 500 kg of calcium carbonate for beating and papermaking, and prepare 10% potassium tartrate, 3% sodium tartrate, 3% zinc acetate and 8% bicarbonate Potassium mixed additive solution, the prepared additive solution is evenly added to the cigarette paper in the sizing section of the cigarette paper production through the metering rod film transfer sizing machine, and the cigarette paper is produced according to the conventional papermaking method, and the parameters of the cigarette paper are controlled on the equipment For: Quantitative 29g m -2 , the air permeability is 60CORESTA, the amount of additive added in the cigarette paper is 1.00g m -2 (No. S2). The prepared functional cigarette paper S2 and the reference cigarette paper S1 were used in the production of a certain brand of cigarettes of China Tobacco Hunan, and the conventional smoke data analysis of mainstream smoke CO, tar, and seven harmfu...

Embodiment 3

[0037] Get 150 kilograms of coniferous wood pulp, 420 kilograms of birch broad-leaved pulp, add 500 kilograms of calcium carbonate for beating and papermaking, prepare potassium fumarate with a mass percentage of 7%, sodium tartrate of 3%, cerium acetate of 2% and 5% of Sodium bicarbonate mixed additive solution, the prepared additive solution is evenly added to the cigarette paper in the sizing section of the cigarette paper production through the metering rod film transfer sizing machine, and the cigarette paper is produced according to the conventional papermaking method, and the cigarette paper is controlled on the equipment. Paper parameters are: Quantitative 29g m -2 , air permeability 60CORESTA, the amount of additives added in cigarette paper is 1.10g m -2 (No. S3). The prepared functional cigarette paper S3 and the reference cigarette paper S1 were used in the production of a certain brand of cigarettes of China Tobacco Hunan, and the conventional smoke data analysis...

Embodiment 4

[0039] Get 150 kilograms of coniferous wood pulp, 420 kilograms of birch broadleaf pulp, add 500 kilograms of calcium carbonate and carry out pulping and papermaking, the preparation mass percentage is 10% potassium tartrate, 2% sodium fumarate, 3% zinc acetate, 2% Cerium acetate and 10% potassium chlorate mixed additive solution, the prepared additive solution is evenly added to the cigarette paper in the sizing section of the cigarette paper production through the metering rod type film transfer sizing machine, and the cigarette paper is produced according to the conventional papermaking method. The cigarette paper parameters controlled on the device are: quantitative 29g m -2 , air permeability 60CORESTA, the amount of additives added in cigarette paper is 0.92g m -2 (No. S4). The prepared functional cigarette paper S4 and the reference cigarette paper S1 were used in the production of a certain brand of cigarettes of China Tobacco Hunan, and the conventional smoke data an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com