Bi-crosslinked gel foam based on polyphenol hydroxyl structure and preparation method thereof

A technology of polyphenol hydroxyl and gel foam, which is applied in the direction of fire prevention equipment, etc., can solve the problems of poor stability, achieve the effects of overcoming poor stability, excellent inhibition of coal oxidation and fire extinguishing effect, and excellent fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 0.8g of sodium alginate and fully dissolve it in 98.35g of water, then add 0.1g of tea saponin and 0.2g of alkyl glycoside in proportion, after mixing evenly, add 0.15g of L-calcium lactate and 0.4g of Tannic acid, by mechanical agitation, forms a double cross-linked gel foam based on the structure of polyphenolic hydroxyl groups.

[0023] The prepared double-crosslinked gel foam was poured into a beaker, and the gelation time of the gel foam was measured by the inversion method. The results showed that the gelation time of the double-crosslinked gel foam was 1 min. Put 50g of coal samples treated with 21.4g of double cross-linked gel foam in a vacuum oven, and treat them under vacuum conditions at 30°C for 24 hours, and then conduct temperature-programmed oxidation tests and gas chromatograph analysis to record the process of coal sample temperature programming CO production in . The results show that the CO release rate of the treated coal sample is low before ...

Embodiment 2

[0027] Weigh 0.6g of sodium alginate and fully dissolve it in 98.2g of water, then add 0.1g of tea saponin and 0.2g of alkyl glycoside in proportion, after mixing evenly, add 0.1g of L-calcium lactate and 0.8g of Tannic acid, by mechanical agitation, forms a double cross-linked gel foam based on the structure of polyphenolic hydroxyl groups.

[0028] The gelation time was measured by the same method as in Example 1, and the results showed that the gelation time of the double cross-linked gel foam was 10min. The temperature-programmed oxidation test combined with gas chromatograph analysis shows that the CO release rate of the treated coal sample is low before 170°C, and the coal is in the slow oxidation stage at this temperature; after 170°C, the CO release rate is significantly accelerated, and the coal enters the rapid oxidation stage. stage, and finally at 200°C, the amount of CO released reached 5407.08ppm.

Embodiment 3

[0030] Weigh 0.4g of sodium alginate and fully dissolve it in 98.05g of water, then add 0.1g of tea saponin and 0.2g of alkyl glycoside in proportion, after mixing evenly, add 0.05g of L-calcium lactate and 1.2g of Tannic acid, by mechanical agitation, forms a double cross-linked gel foam based on the structure of polyphenolic hydroxyl groups.

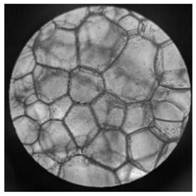

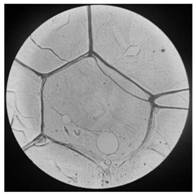

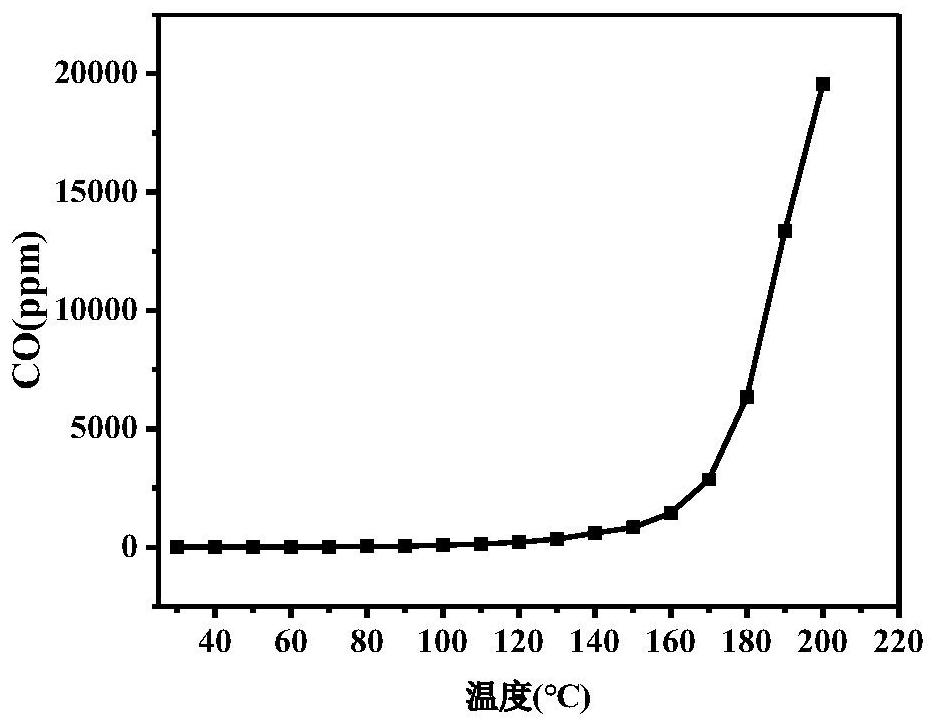

[0031] Using the same method as in Example 1, the gelling time shows that the gelling time of this double-crosslinked gel foam is 15min; the double-crosslinked gel foam is analyzed for microstructure, and the results are as follows figure 2 As shown in the microstructure diagram of the double-crosslinked gel foam, it can be seen from the figure that the formed gel foam structure is relatively uniform and regular; the half-life of the gel foam measured by the standing method is 26 days; the double-crosslinked The CO release curve of the coal sample treated with gel foam during the temperature-programmed oxidation test is as follows i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com