A method for reducing cigarette CO and tar release

A technology of emission and cigarettes, which is applied in the fields of e-liquid filter elements, tobacco, and processed tobacco, can solve problems affecting the health of smokers, achieve the effects of promoting combustion efficiency, improving comfort, and reducing CO emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

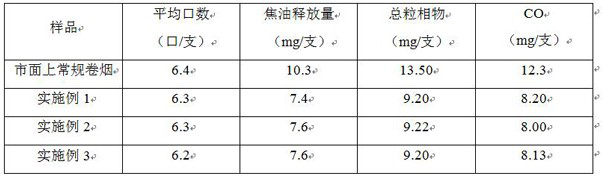

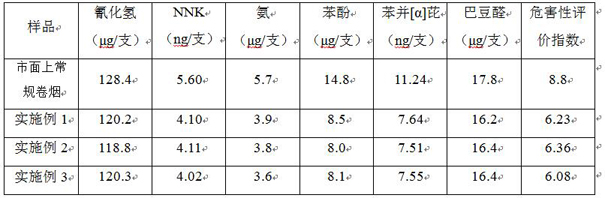

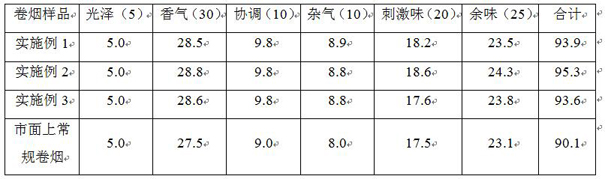

Examples

Embodiment 1

[0045] 1. Preparation of modified dolomite powder

[0046] (1) According to the ratio of parts by weight, weigh 10 parts of dolomite powder, according to NaNO 3 Soluble in NaNO with a mass ratio of 0.1:1 to dolomite powder 3 It was configured into a solution, stirred at 80°C for 15 minutes, and then dried at 120°C for 2 hours to obtain composite dolomite powder;

[0047] (2) Treat the composite dolomite powder in an argon discharge plasma system for 1 hour, a total of 6 times for 10 minutes each time, to obtain modified dolomite powder;

[0048] The argon gas discharge plasma system is pumped into argon gas after vacuuming to stabilize the pressure at 100 Pa, and then connected to a DC power supply. The breakdown voltage is 900V, the stable voltage is 600V, and the current is 9mA.

[0049] 2. Preparation of hyperbranched lactate

[0050] Mix 50 parts of sodium lactate, 10 parts of lactic acid, 1 part of glycerol, and 3 parts of gluconic acid according to the ratio of parts ...

Embodiment 2

[0064] 1. Preparation of modified dolomite powder

[0065] (1) According to the ratio of parts by weight, weigh 15 parts of dolomite powder, according to NaNO 3 Soluble in NaNO with a mass ratio of 0.2:1 to dolomite powder 3 It was prepared into a solution, stirred at 80°C for 15-20min, and then dried at 120°C for 2h to obtain composite dolomite powder;

[0066] (2) Treat the composite dolomite powder in an argon discharge plasma system for 1 hour, a total of 6 times for 10 minutes each time, to obtain modified dolomite powder;

[0067] The argon gas discharge plasma system is pumped into argon gas after being vacuumed to stabilize the pressure at 110 Pa, and then connected to a DC power supply. The breakdown voltage is 900V, the stable voltage is 600V, and the current is 11mA.

[0068] 2. Preparation of hyperbranched lactate

[0069] Mix 70 parts of potassium lactate, 20 parts of lactic acid, 5 parts of glycerol, and 5 parts of gluconic acid according to the ratio of parts...

Embodiment 3

[0079] 1. Preparation of modified dolomite powder

[0080] (1) According to the ratio of parts by weight, weigh 12 parts of dolomite powder, according to NaNO 3 The mass ratio of dolomite powder is 0.2:1; soluble in NaNO 3 It was configured into a solution, stirred at 80°C for 20 minutes, and then dried at 120°C for 2 hours to obtain composite dolomite powder;

[0081] (2) Treat the composite dolomite powder in an argon discharge plasma system for 1 hour, a total of 6 times for 10 minutes each time, to obtain modified dolomite powder;

[0082] The argon gas discharge plasma system is filled with argon gas after vacuuming to stabilize the pressure at 100 Pa, and then connected to a DC power supply with a breakdown voltage of 900V, a stable voltage of 600V, and a current of 10mA.

[0083] 2. Preparation of hyperbranched lactate

[0084] Mix 60 parts of lithium lactate, 15 parts of lactic acid, 3 parts of glycerol, and 4 parts of gluconic acid according to the ratio of parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com