42 CrMo steel cold-rolled sheet and its production method

A production method and technology for cold-rolled sheets, which are applied in the field of steel manufacturing, can solve problems such as cracking and affect formability, and achieve the effects of good toughness, excellent cutting performance, and prevention of cold-rolled cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below by way of examples.

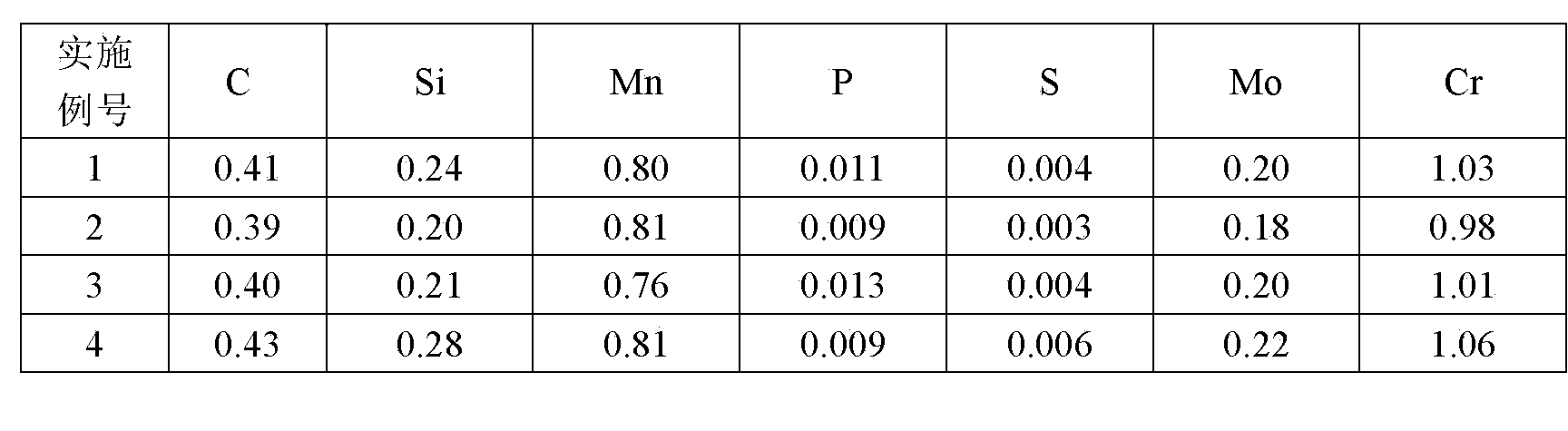

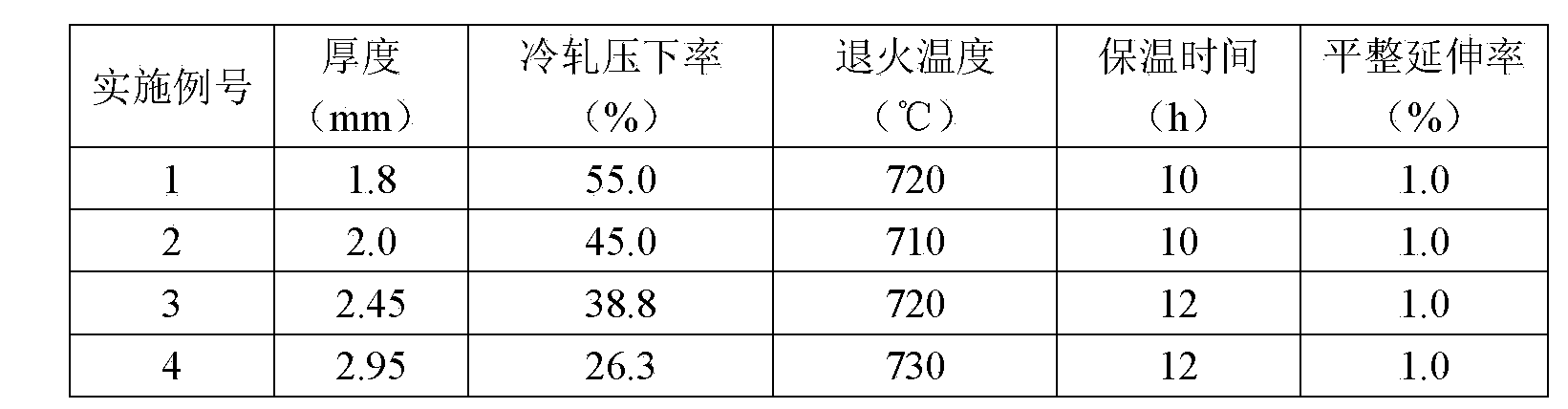

[0026] The composition of the present invention is C: 0.38~0.45, Si: 0.17~0.37, Mn: 0.50~0.90, P: <0.035, S: <0.035, Cr: 1.02~1.14, Mo: 0.15~0.25, and the rest is Fe and not The impurity that avoids, table 1 adopts several optimal embodiments of its composition for the present invention, and carries out hot rolling, cold rolling production under the condition shown in table 2, table 3 by the inventive method, and according to table 3 The conditions shown are spheroidizing annealing by bell annealing method, followed by air cooling after keeping warm at 400°C with a cover. The 42CrMo cold-rolled and annealed sheets with thicknesses of 1.8, 2.0, 2.45, and 2.95 mm are produced by the above-mentioned process, and their mechanical properties are shown in Table 4. The typical metallographic structure of the examples is shown in the accompanying drawings, and the spheroidization grade is the highest. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com