Aluminium bronze continuously-cast tube with both high strength and high ductility, and production method thereof

A production method and high ductility technology, which are applied in the field of aluminum bronze continuous casting pipes with both high strength and high ductility and their production fields. The effect of market competitive advantage, excellent comprehensive performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

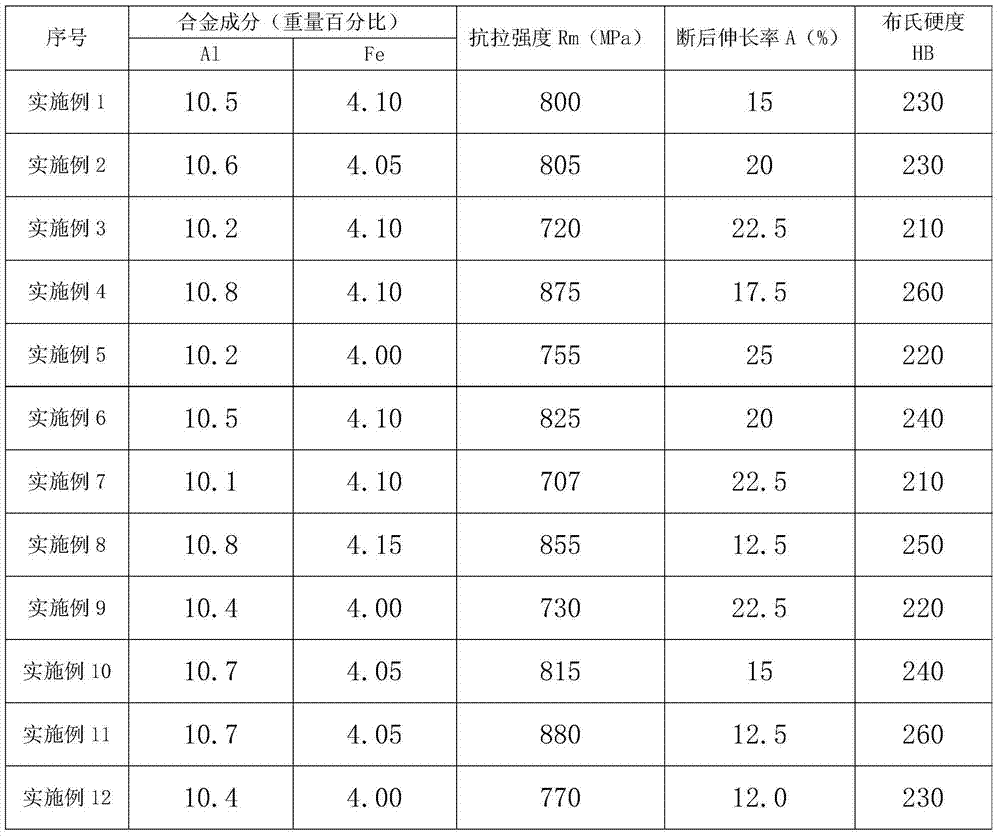

Examples

Embodiment Construction

[0040] According to the feeding plan of 10-11.5% (weight) of aluminum, 4-5% (weight) of iron, and the balance of copper, a cored power frequency induction furnace is used to batch ingredients according to the furnace body capacity. First add 2 / 3 copper + 1 / 3 aluminum + iron in the furnace, cover with 0.1% cryolite according to the feeding amount, raise the furnace temperature to 1300°C after the copper is melted, add 1 / 3 copper to cool down and add 2 / 3 aluminum, add cryolite to remove slag after melting again, heat up to 1100-1200 ℃ for drawing and casting. During the drawing-casting process, add aluminum at 0.5% of the total weight of the feed every hour to make up for the loss of aluminum during the drawing-casting process (of course, this loss can also be ignored without adding aluminum). The drawing temperature is 1100-1200°C, the drawing length is 8-15mm, the drawing frequency is 6-15 times / min, and the rest time is 3-8 seconds. The cooling adopts the combination of pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com