Desulfurization refining slag for steelmaking process and addition method thereof

A technology of refining slag and desulfurization slag, which is applied in the direction of improving process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

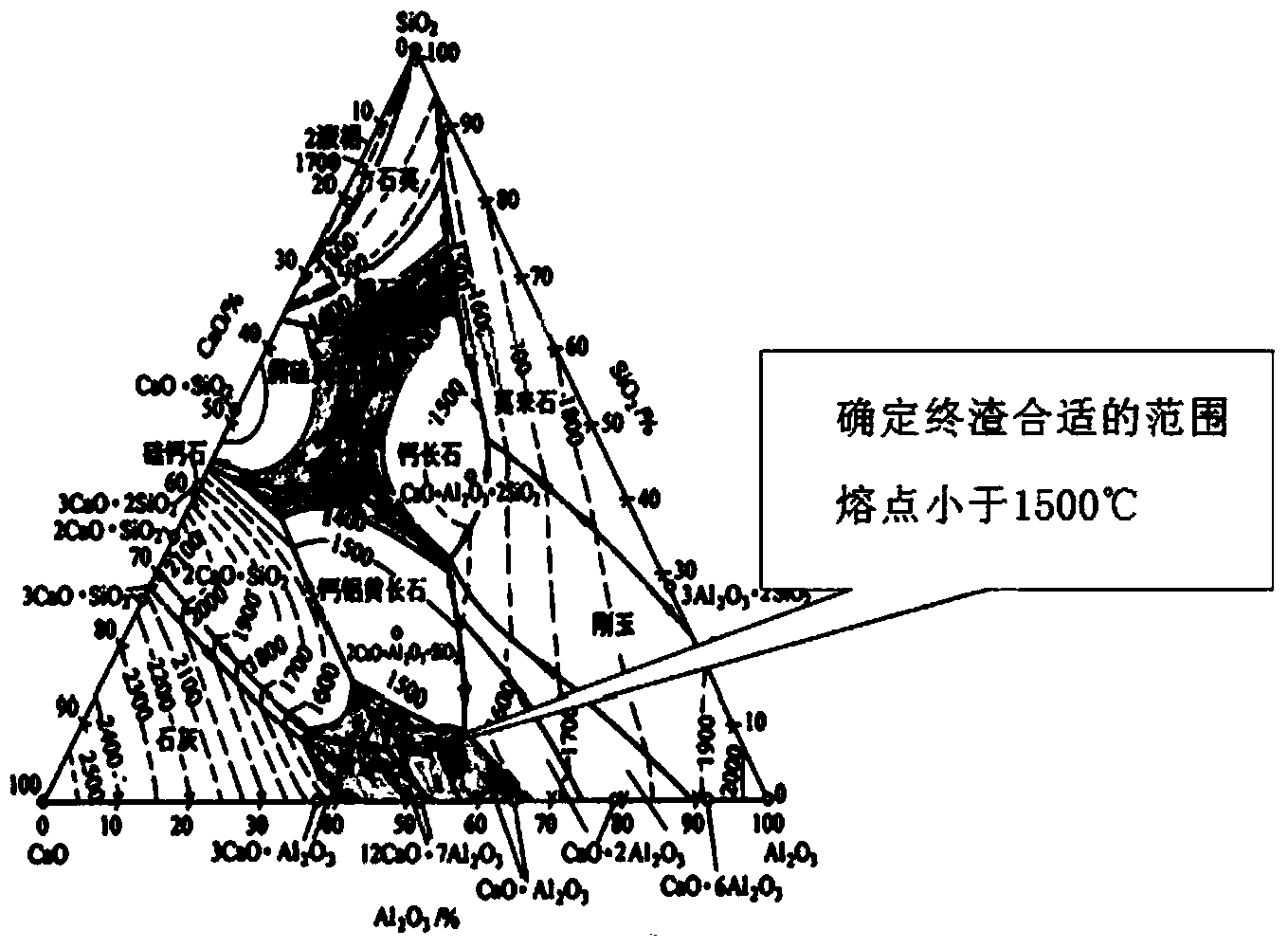

[0025] Such as figure 1 figure 2 As shown, the technical solution provided by the present invention is a desulfurization refining slag used in the steelmaking process, the refining slag components include CaO, SiO 2 、Al 2 o 3 , MgO, the proportion of each component is CaO=50%~60%, SiO 2 =7%~12%, Al 2 o3 =28%~33%, MgO=4%~8%. The amount of slag is set at 12-15kg / ton of steel. The CaO and Al 2 o 3 The ratio of CaO% / Al 2 o 3 %=1.8, according to the above CaO and Al 2 o 3 The ratio corresponds to the amount of lime added.

[0026] A method for adding desulfurization refining slag in the steelmaking process provided by the present invention is as follows:

[0027] (1) Add slag:

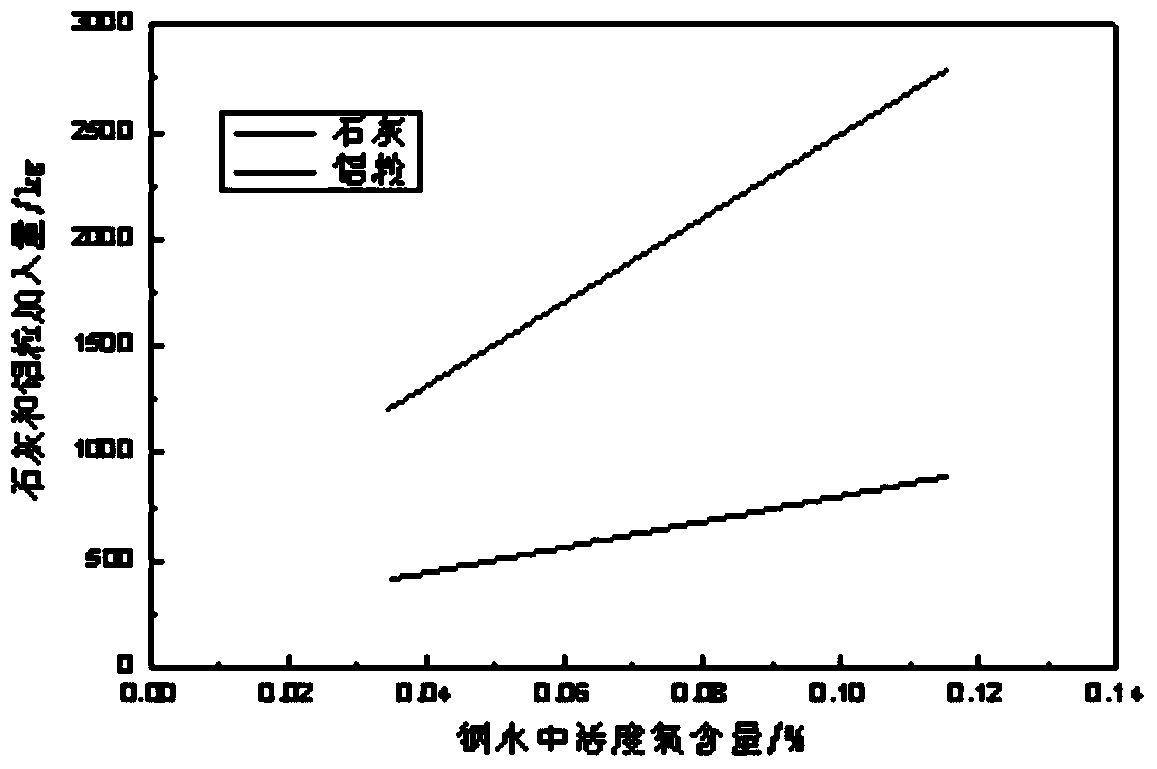

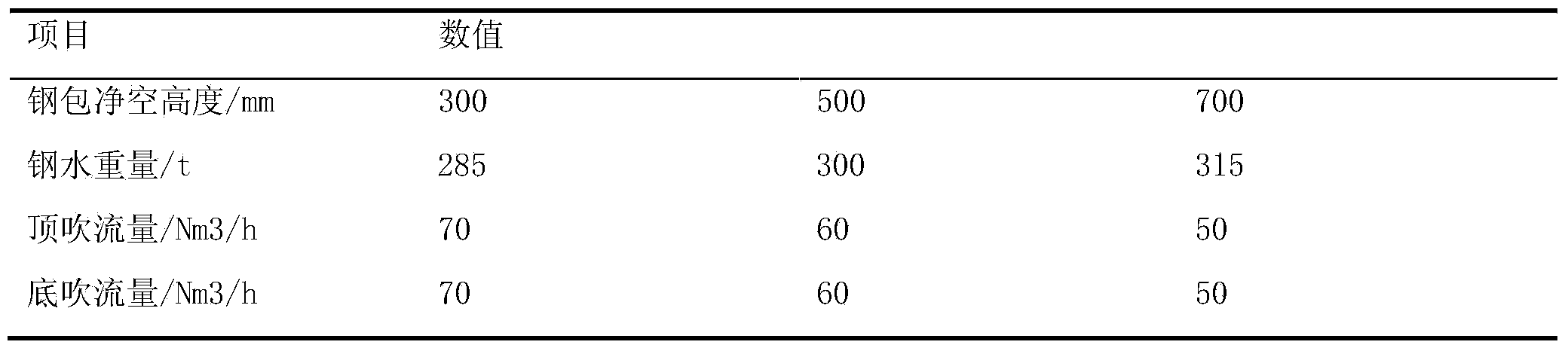

[0028] The slag is mainly added during the tapping process, and the Al 2 o 3 For slagging, the total slag amount is controlled according to 12-15kg / ton of steel. In the case of controlling the total slag amount, it is generally based on the content of active oxygen at the end of the conver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com