A kind of conductive paint with self-cleaning function and its preparation method and application

A conductive coating, self-cleaning technology, applied in conductive coatings, epoxy resin coatings, antifouling/underwater coatings, etc., can solve the problems of low surface energy, high cost, pollution, etc., achieve excellent conductivity, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Preparation of a conductive coating with self-cleaning function

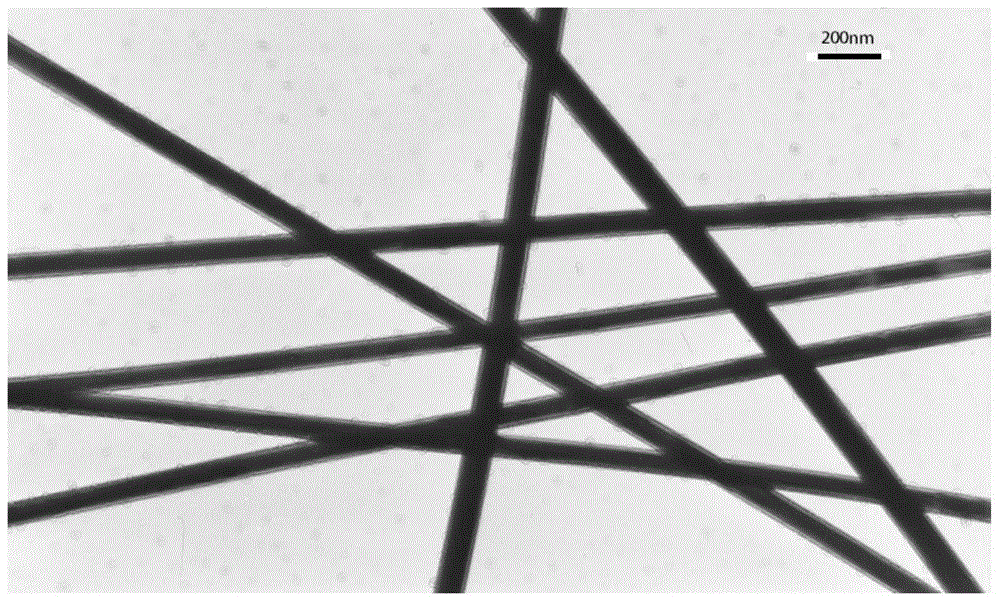

[0052] (1) Preparation of modified nano-silver wires: Add silver salt, guiding agent, metal salt, and solvent A into the reaction flask at a temperature of 20°C, stir and dissolve, and heat up the reaction system after the reactants are completely dissolved. to 180°C, constant temperature reaction for 1 hour, to obtain linear nano-silver, then add low surface energy substance B, continue to react for 2 hours, and then ultrasonic for 10 minutes, and finally wash and centrifuge with acetone for 3 times to obtain modified linear nano-silver, which was subjected to TEM Scan and observe, see the results figure 1 . Redissolve the modified silver nanowires with solvent C to obtain the desired modified silver nanowire solution.

[0053] Among them, the mass ratio of silver salt, guiding agent, metal salt, solvent, and low surface energy material B: 1:1.2:1.3×10 -3 :100:0.2;

[0054] Among them, ...

Embodiment 2

[0069] Embodiment 2: Preparation of a conductive coating with self-cleaning function

[0070] (1) Preparation of modified nano-silver wires: Add silver salt, guiding agent, metal salt, and solvent A into the reaction flask at a temperature of 20°C, stir and dissolve, and heat up the reaction system after the reactants are completely dissolved. To 180°C, constant temperature reaction for 1 hour to obtain linear nano-silver, then add low surface energy substance B, continue to react for 2 hours, then ultrasonic for 10 minutes, finally wash and centrifuge with acetone for 3 times to obtain modified linear nano-silver. Redissolve the modified silver nanowires with solvent C to obtain the desired modified silver nanowire solution.

[0071] Among them, the mass ratio of silver salt, guiding agent, metal salt, solvent, and low surface energy material B: 1:1.2:1.3×10 -3 :100:0.2;

[0072] Among them, the silver salt is: AgNO 3 ;

[0073] The guiding agent is: polyethylene glycol; ...

Embodiment 3

[0087] Embodiment 3: Preparation of a conductive coating with self-cleaning function

[0088] (1) Preparation of modified nano-silver wires: Add silver salt, guiding agent, metal salt, and solvent A into the reaction flask at a temperature of 20°C, stir and dissolve, and heat up the reaction system after the reactants are completely dissolved. To 180°C, constant temperature reaction for 1 hour to obtain linear nano-silver, then add low surface energy substance B, continue to react for 2 hours, then ultrasonic for 10 minutes, finally wash and centrifuge with acetone for 3 times to obtain modified linear nano-silver. Redissolve the modified silver nanowires with solvent C to obtain the desired modified silver nanowire solution.

[0089] Among them, the mass ratio of silver salt, guiding agent, metal salt, solvent, and low surface energy material B: 1:1.2:1.3×10 -3 :100:0.2;

[0090] Among them, the silver salt is: AgNO 3 ;

[0091] The guiding agent is: polyethylene glycol; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com