Water-based transparent colored paint for wooden ware and preparation method of paint

A transparent color and wood technology, applied in the field of coatings, can solve problems such as low VOC content and high pollution, achieve the effect of reducing defects, reducing VOC content, and ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

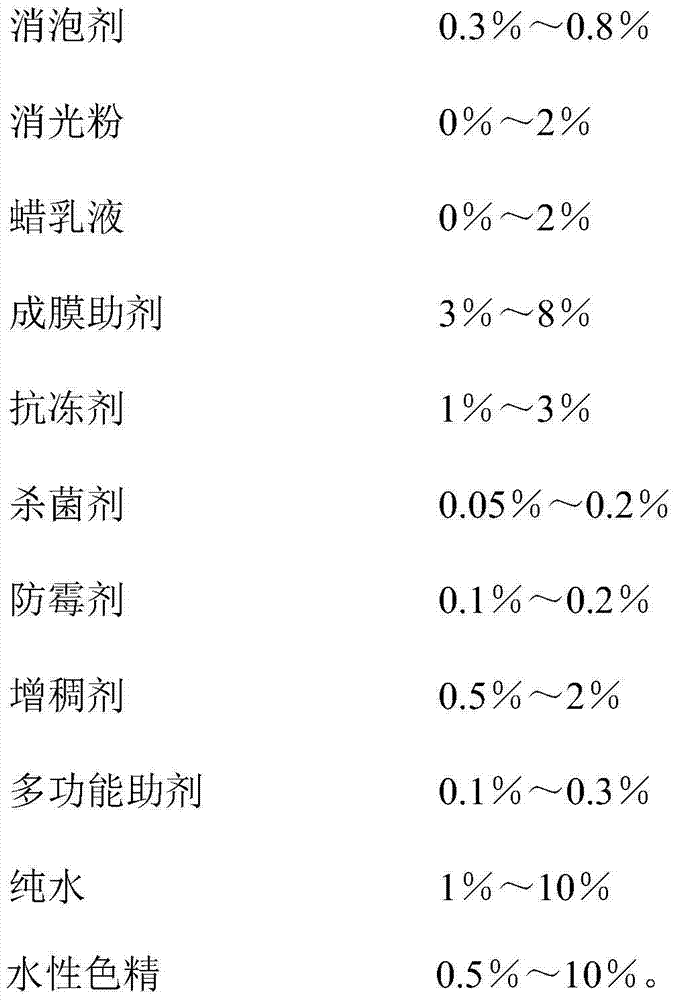

[0035] Preparation of a kind of water-based wood transparent paint step of the present embodiment is as follows (both percentages by weight):

[0036] (1) At room temperature, add 86.5% water-based acrylic emulsion to the reaction kettle, and add 0.3% polycarboxylic acid wetting and dispersing agent, 0.2% polyether-modified polysiloxane fluid under low-speed (~500rpm) stirring Leveling agent, 0.3% defoamer, stirring (~500rpm) for 5 minutes;

[0037] (2) Add 1% matting powder, 0.5% synthetic wax wax emulsion, disperse at high speed (~1500rpm) for 15 minutes, until the fineness is ≤30 microns;

[0038] (3) Add 0.3% defoamer, 5% film-forming agent CS-12, 1.5% propylene glycol, 0.1% fungicide, 0.2% anti-fungal agent, 1.2% thickener, 0.2% PH regulator, 1.5% pure water , stir at medium speed (~800rpm) for 15 minutes at room temperature;

[0039] (4) Add 1.2% water-based color essence, stir at low speed (~500rpm) for 10 minutes to get the finished product.

Embodiment 2

[0041] Preparation of a kind of water-based wood transparent paint step of the present embodiment is as follows (both percentages by weight):

[0042] (1) At room temperature, add 52% water-based acrylic acid emulsion and 28% water-based polyurethane dispersion to the reaction kettle, and add 0.3% polycarboxylic acid wetting and dispersing agent, 0.3% polyacrylic acid under low-speed (~500rpm) stirring state Leveling agent, 0.3% defoamer, stirring (~500rpm) for 5 minutes;

[0043] (2) Add 0.5% matting powder and 0.8% oxidized polyethylene wax emulsion, and disperse at high speed (~1500rpm) for 15 minutes until the fineness is ≤30 microns;

[0044] (3) Add 0.3% defoamer, 4% film-forming agent DPM, 2% film-forming agent DPnB, 2% propylene glycol, 0.1% fungicide, 0.2% anti-fungal agent, 1.6% thickener, 0.2% PH regulator , 5.6% pure water, stirring at medium speed (~800rpm) for 15 minutes at room temperature;

[0045] (4) Add 1.8% water-based color essence, stir at low speed (~5...

Embodiment 3

[0048] Preparation of a kind of water-based wood transparent paint step of the present embodiment is as follows (both percentages by weight):

[0049] (1) At room temperature, add 84% water-based polyurethane dispersion to the reaction kettle, and add 0.6% polysiloxane wetting and dispersing agent, 0.3% polyacrylic acid leveling agent, 0.3 % defoamer, stirring (~500rpm) for 5 minutes;

[0050] (2) Add 0.7% matting powder and 0.5% oxidized polyethylene wax emulsion, and disperse at high speed (~1500rpm) for 15 minutes until the fineness is ≤30 microns;

[0051] (3) Add 0.3% defoamer, 3.5% film-forming agent DPnB, 1.5% propylene glycol, 0.1% fungicide, 0.2% anti-fungal agent, 0.9% thickener, 0.2% multifunctional additive, 4.4% pure water, Stir at medium speed (~800rpm) for 15 minutes at room temperature;

[0052] (4) Add 2.5% water-based color essence, stir at low speed (~500rpm) for 10 minutes to get the finished product.

[0053] Make performance comparison with embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com