Wear-resistant halogen-free flame-retardant elastic material for high-speed elevator flat cable and preparation method thereof

An elastic material and elastomer technology, applied in circuits, electrical components, rubber insulators, etc., can solve the problems of human health hazards, harmful substances, environmental hazards, etc., and achieve the effects of simple process, low cost, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

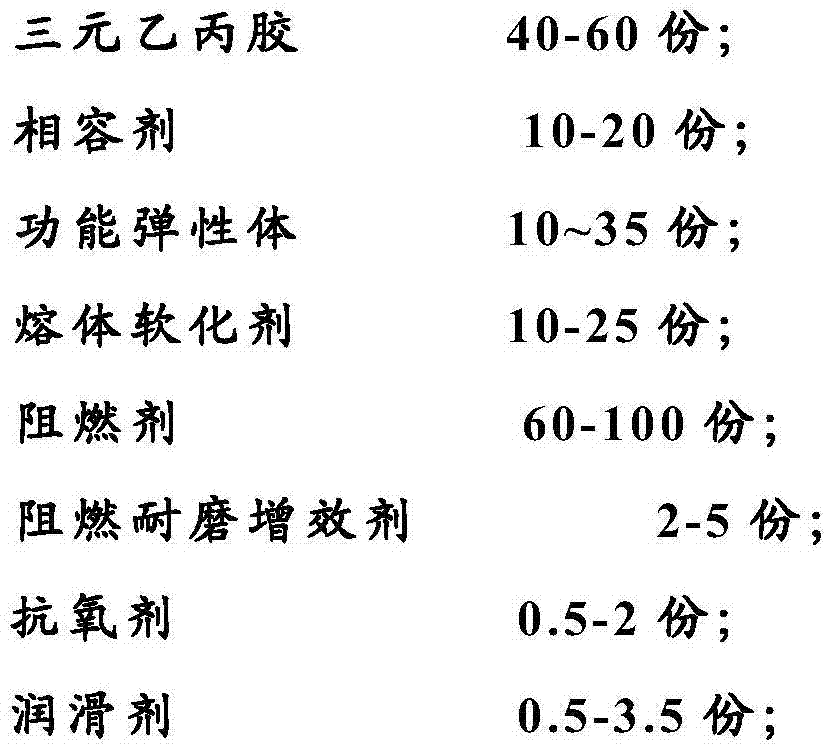

Method used

Image

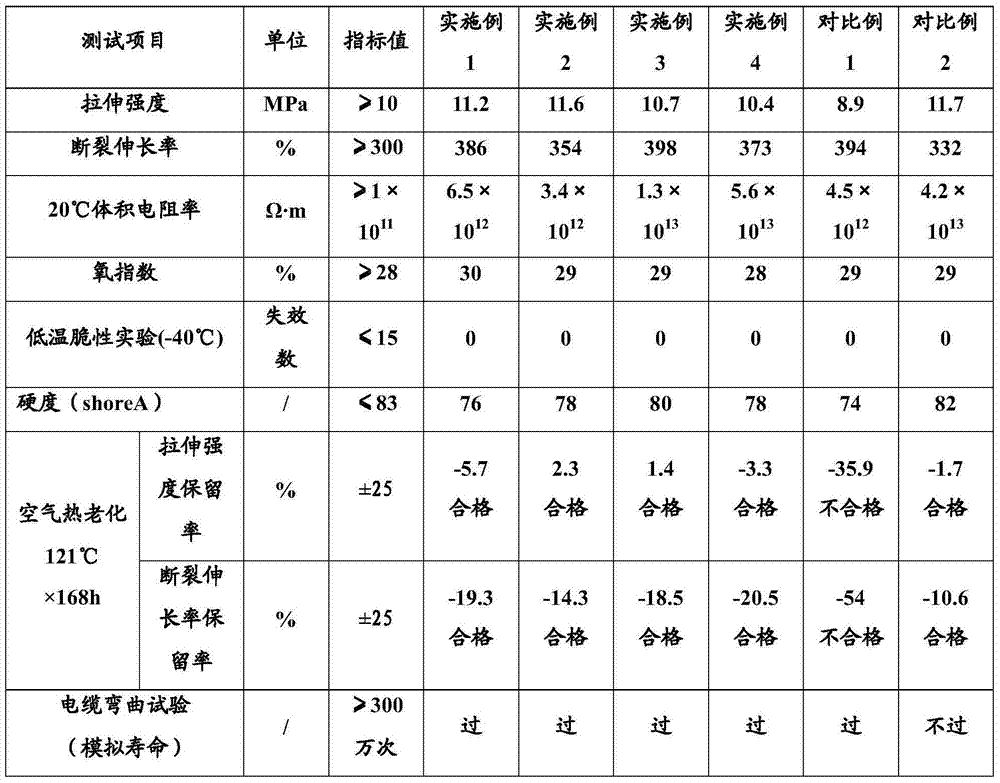

Examples

Embodiment 1

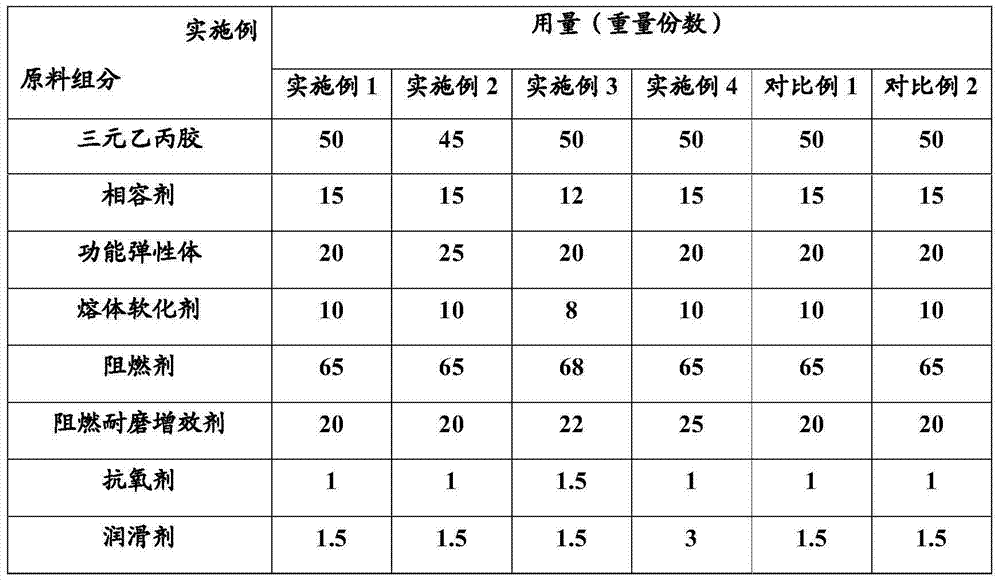

[0027] This example provides a method for preparing a wear-resistant halogen-free flame-retardant elastic material. The raw materials and dosages used are shown in Table 1, wherein:

[0028] EPDM rubber: The mass content of ethylene is 70%, the mass content of the third monomer is 4.9%, and the Mooney viscosity of EPDM is 25. Among them, EPDM comes from Dow Chemical;

[0029] Compatibilizer: Maleic anhydride grafted EPDM copolymer with Shore A hardness of 72;

[0030] Functional elastomer: composed of TPU and SEBS at a mass ratio of 1:0.6, among which, TPU comes from BASF, and SEBS comes from Yueyang Petrochemical;

[0031] Melt softener: choose ethylene-vinyl acetate copolymer with a melt index of 20g / 10min, and the melt index is obtained by testing at 190°C and 21.6KG pressure;

[0032] Flame retardant: It is composed of surface-treated aluminum hydroxide and surface-treated magnesium hydroxide in a mass ratio of 1:2. Among them, the surface-treated aluminum hydroxide come...

Embodiment 2

[0039] This example provides a preparation method of a wear-resistant halogen-free flame-retardant elastic material. The raw materials and dosage used are shown in Table 1. The raw materials other than EPDM rubber and functional elastomer are the same as those in Example 1.

[0040] In this example, the EPDM rubber has a mass content of 67% of ethylene, a mass content of the third monomer of 4.9%, and the Mooney viscosity of the EPDM rubber is 60.

[0041] In this example, the functional elastomer is composed of TPU and SEBS at a mass ratio of 1:1.

[0042] The preparation process of the wear-resistant halogen-free flame-retardant elastic material is the same as that in Example 1.

Embodiment 3

[0044] This example provides a preparation method of a wear-resistant halogen-free flame-retardant elastic material. The raw materials and dosages used are shown in Table 1. The raw materials other than the compatibilizer, melt softener and antioxidant are the same as in Example 1.

[0045] In this example, the compatibilizer is a maleic anhydride grafted ethylene-vinyl acetate copolymer with a Shore A hardness of 85.

[0046] In this example, the melt softener is an ethylene-octene copolymer with a melt index of 20g / 10min, and the melt index is obtained by testing at 190°C and a pressure of 21.6KG.

[0047] In this example, the antioxidant is composed of antioxidant DLTP and antioxidant 1010 in a mass ratio of 1:0.5.

[0048] The preparation process of the wear-resistant halogen-free flame-retardant elastic material is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com