CPE pattern isolating membrane of glass interlayer PVB membrane and production method thereof

A technology of isolation film and interlayer, which is applied in the field of CPE isolation film, to achieve the effect of good surface smoothness and smoothness, not easy to absorb dust, and high authenticity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

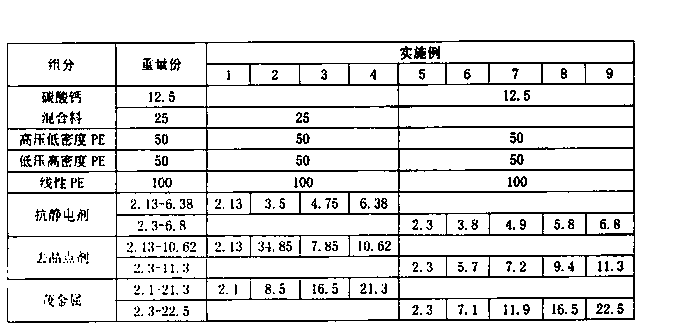

[0022] Embodiment 1 (composition of corresponding embodiment in the comparison table and the proportioning value thereof by weight):

[0023] First prepare the calcium carbonate mixture, mix well with 25 parts of this material, 50 parts of high-pressure low-density PE, 50 parts of low-pressure high-density PE, 100 parts of linear PE, 2.13 parts of antistatic agent, 2.13 parts of decrystallization agent, and 2.1 parts of metallocene Finally, bake at 80°C for 2 hours until the moisture content is ≤ 2%, put it into the screw extruder, and extrude it in hot melt until it becomes jelly. Pressed into a wide film, then drawn, coiled and slitting. After passing the inspection, it is packaged, put into storage and stacked or leaves the factory.

[0024] Among the nine embodiments, the products in the first 1-4 items are suitable for the needs of domestic consumers, and the products in the latter 5-9 items are suitable for export. Wherein preferred with embodiment 2,3,7.

[0025] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com