Preparation method of high-performance waterborne epoxy curing agent

A water-based epoxy and curing agent technology, applied in the direction of epoxy resin coatings, coatings, etc., to achieve high hardness, high cross-linking density, and good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

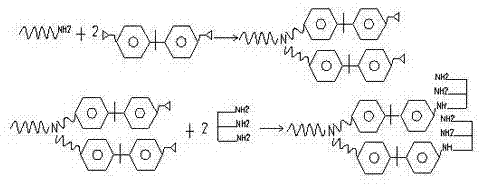

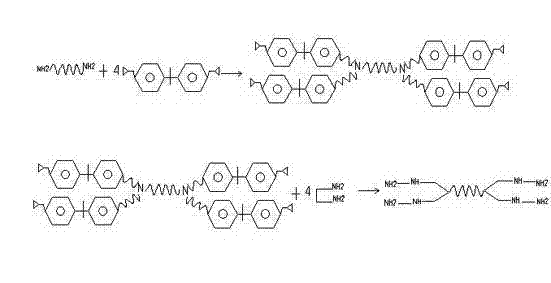

Method used

Image

Examples

Embodiment 1

[0028] Take 1mol of M2070 and add it to a beaker with a constant temperature water bath, and add 2mol of liquid epoxy resin DER331, start the stirrer, set the speed at 600-1000 rpm, heat up to 70 degrees Celsius while stirring, and keep it for 3 hours to get a viscous 1mol of intermediate A, continue to stir, quickly add 2mol of polyetheramine T403 at one time, for exothermic reaction, turn on the cold water cooling water bath, control the temperature of the reactant below 80 degrees Celsius, mix for 120 minutes, and the reaction product is clear, transparent and viscous Liquid, add 10% nonylphenol, 8% benzyl alcohol, 4% AEP, and finally add 50% deionized water according to the weight ratio of the reactants, and mix well to obtain the final product water-based epoxy curing agent. Take 60-70 After mixing 100 parts of this product with 100 parts of standard liquid epoxy resin DER331, the liquid epoxy resin can be directly emulsified into a white emulsion, and the cured coating fi...

Embodiment 2

[0030] Take 0.5 mol of ED2003 and add it into a beaker with a constant temperature water bath to melt, and add 2 mol of liquid epoxy resin DER331, start the stirrer, set the speed at 600-1000 rpm, heat up to 70 degrees Celsius while stirring, and keep it for 3 hours to obtain a viscous Thick 1mol intermediate B, continue to stir, quickly add 1mol polyetheramine T403 and 1mol polyetheramine D230 at one time, for exothermic reaction, turn on the cold water cooling water bath, control the temperature of the reactant below 80 degrees Celsius, mix for 120 minutes, and get The reaction product is a clear, transparent and viscous liquid. According to the weight ratio of the reactants, 10% nonylphenol, 8% benzyl alcohol, 4% AEP, and finally 50% deionized water are added, and the final product is obtained. Oxygen curing agent, after mixing 60-70 parts of this product with 100 parts of standard liquid epoxy resin DER331, the liquid epoxy resin can be directly emulsified into a white emul...

Embodiment 3

[0032] Take 0.5 mol of ED900 and add it to a beaker with a constant temperature water bath to melt, and add 2 mol of liquid epoxy resin DER331, start the stirrer, set the speed at 600-1000 rpm, heat up to 70 degrees Celsius while stirring, and keep it for 3 hours to obtain a viscous Thick 1mol intermediate B, continue to stir, quickly add 2mol vinylamine DETA at one time, for exothermic reaction, turn on the cold water cooling water bath, control the temperature of the reactant below 80 degrees Celsius, mix for 120 minutes, and the reaction product is clear, transparent and viscous The liquid of adding 10% nonylphenol, 8% salicylic acid by reactant weight ratio, 4% AEP, finally adding 50% deionized water, mix uniformly, obtain final product water-based epoxy curing agent, take 60% - After mixing 70 parts of this product with 100 parts of standard liquid epoxy resin DER331, the liquid epoxy resin can be directly emulsified into a white emulsion, and the cured coating film is har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com