Microorganism water purification agent and preparation method thereof

A preparation process and microbial technology, applied in the field of microorganisms, can solve problems such as eutrophication and easy destruction of water quality, and achieve the effects of maintaining quality, better purification effect, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

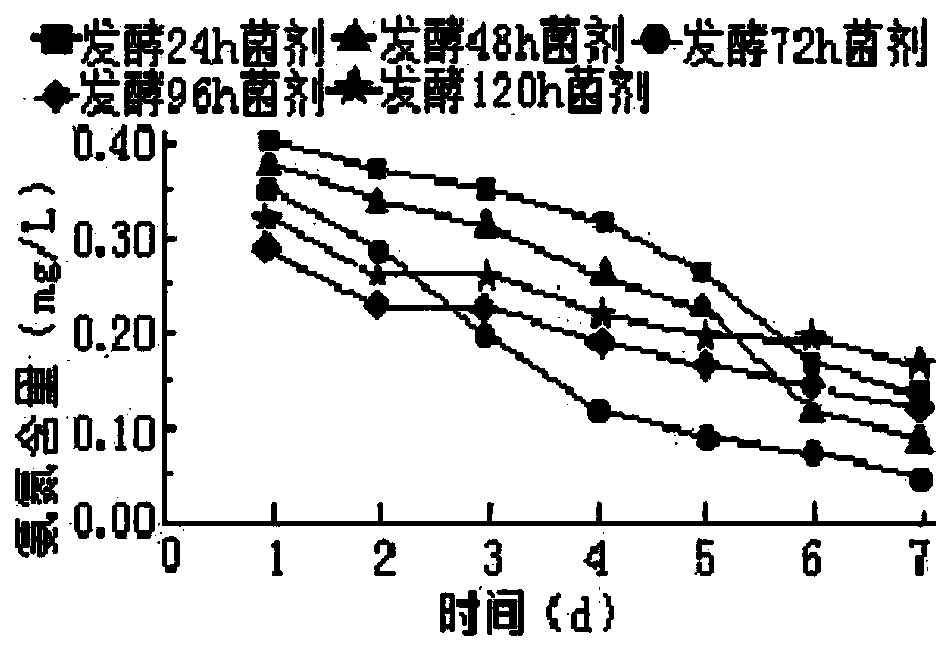

[0031] Select 1500ml of No. 1, 2, 3, 4, and 5 mediums in Table 1, respectively, and put each medium into a 25L fermenter, sterilize at 120°C for 20min, and inoculate after the medium cools down. The agent is a liquid bacterial agent containing 18.75ml of Bifidobacteria, 22.5ml of Candida tropicalis and 33.75ml of Bacillus subtilis, and the inoculum is 75ml. Initially, the pH in the fermenter was 6.8, the fermentation temperature was 30°C, anaerobic fermentation was carried out under the condition of no ventilation and the stirring speed was 250r / min, and 100ml samples were taken every 24 hours for the fermenter, and a total of 5 samples were taken, that is, each fermentation Tank fermentation stops after 120h.

Embodiment 2

[0033] Sugar cane molasses: 38.7ml sucrose, 10.8ml glucose, 13.5ml fructose, 3.6ml carbohydrates, 23.4ml water. Preparation of sugarcane molasses medium: sugarcane molasses 90ml, NH with a mass concentration of 1.0% 4 Cl7.5ml, KH with a mass concentration of 0.5% 2 PO 4 22.5ml, 1# trace element 7.5ml, purified water 1372.5ml. Measure 1500ml, put it into a 25L fermenter, sterilize at 100°C for 25min, inoculate after cooling the culture medium, the bacterial agent is 9ml of Bifidobacterium, 15.75ml of Candida tropicalis and 20.25ml of subtilis The liquid inoculum of Bacillus, the inoculum size is 45ml. Initially, the pH in the fermenter is 6.8, the fermentation temperature is 30°C, anaerobic fermentation is carried out for 72 hours under the condition of no ventilation and the stirring speed is 200r / min, and the microbial agent for purifying aquaculture water quality of the present invention is obtained.

Embodiment 3

[0035] Sugarcane molasses: 28.2ml sucrose, 4.8ml glucose, 11.4ml fructose, 1.2ml carbohydrate, 14.4ml water. Preparation of sugarcane molasses medium: take 60ml of sugarcane molasses and NH with a mass concentration of 2.0% by volume percentage 4 Cl37.5ml, KH with a mass concentration of 1.2% 2 PO 44.5ml, 1.5ml of 2# trace elements, 1396.5ml of distilled water. Measure 1500ml, put it into a 25L fermenter, sterilize at 130°C for 15min, inoculate after cooling the culture medium, the bacterial agent is 36ml of Bifidobacterium, 36ml of Candida tropicalis and 48ml of Bacillus subtilis The liquid bacterial agent, the inoculation volume is 120ml. Initially, the pH in the fermenter was 6.8. During the fermentation process, the fermentation temperature was 30° C., and the anaerobic fermentation was carried out for 72 hours without ventilation and the stirring speed was 300 r / min, and the bacterial agent for purifying aquaculture water quality of the present invention was obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com