Straw micro-stage additive and preparation method thereof

An additive and straw technology, applied in the field of microorganisms, can solve problems such as traffic accidents that affect air quality, affect crop growth, reduce soil fertility, etc., achieve the effects of improving the internal and external environment of animals, solving the imbalance of organism flora, and having a wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] 1. Materials:

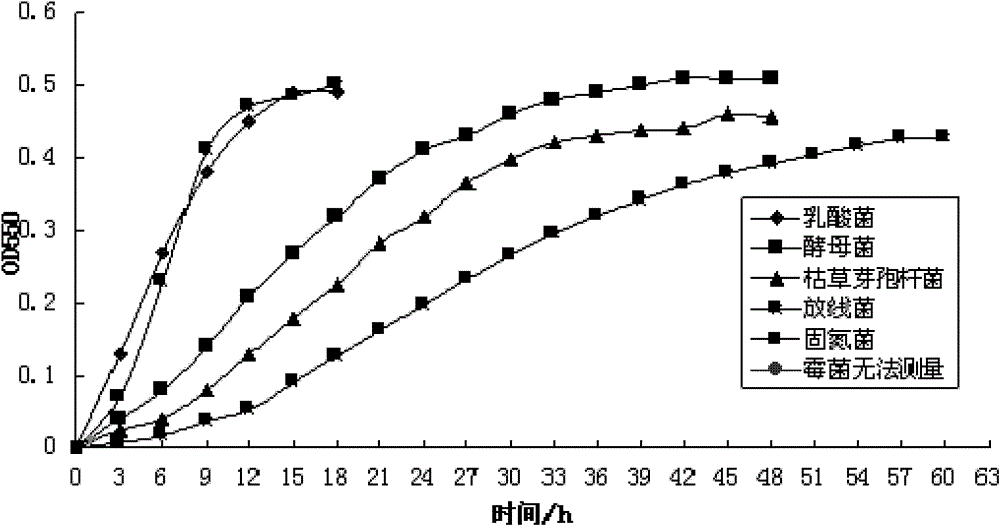

[0047]SW-CJ-1CU ultra-clean workbench, domestic; YXQ-LS-50SI vertical pressure steam sterilizer, domestic; FD-1A-50 freeze dryer, domestic; BIOF-6050A50L mechanical stirring stainless steel intelligent fermentation tank , domestic; TGL low-temperature refrigerated centrifuge, domestic; L2800 microscope, domestic; UVD-3500 ultraviolet spectrophotometer, American Labomed; 3000B electronic balance, American; strains: Saccharomyces cerevisiae, Bacillus subtilis, lactic acid bacteria, Cytobacteria, nitrogen-fixing bacteria, and molds are preserved in the Pharmaceutical Laboratory of the School of Pharmacy and Bioengineering, Chongqing University of Technology.

[0048] 2. Method:

[0049] 2.1 Strain activation:

[0050] Put the preserved brewer's yeast, lactic acid bacteria, Bacillus subtilis, actinomycetes, nitrogen-fixing bacteria, and mold strains into sterilized 1% sugar water to activate for 2 hours, and then transfer them into sterilized bean sprouts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com