Self-reflection calibration method for space remote sensor on orbit infrared focal plane

A space remote sensor, self-reflection calibration technology, used in TV, color TV parts, electrical components, etc., can solve the problems of opto-mechanical structure deformation, many constraints, limited application scope, etc., to achieve temperature stability and Good uniformity, improved imaging quality, and small deformation of optomechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

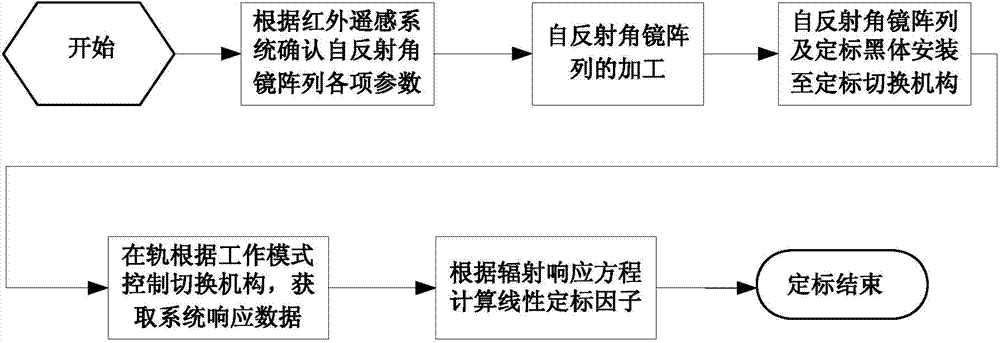

[0031] The space infrared remote sensor referred to in the present invention adopts the combination of refrigerator and radiation refrigeration to refrigerate the detector focal plane assembly, and the refrigeration temperature is 60K~80K, which becomes the cold focal plane; for the secondary imaging off-axis optical system, the calibration The switching mechanism is placed at the position of the primary image plane, and the working mode is switched through the control circuit when it is in orbit, so as to realize the radiation calibration of the imaging system, remove the influence of dark current noise and the background radiation of the local optical path, and realize the process as shown in the attached figure 1 As shown, the steps are as follows:

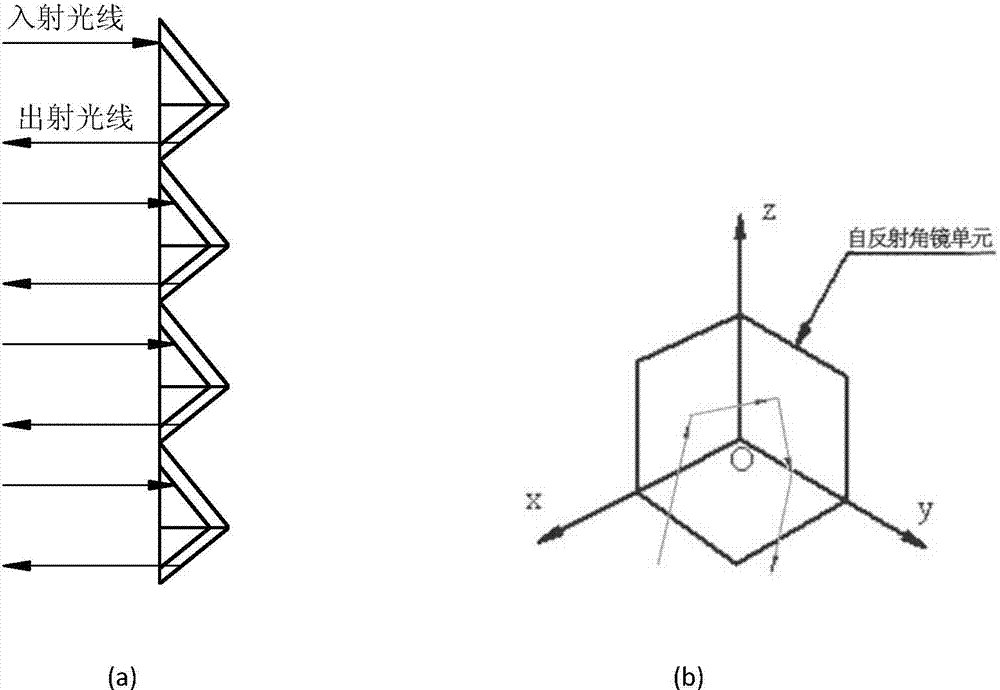

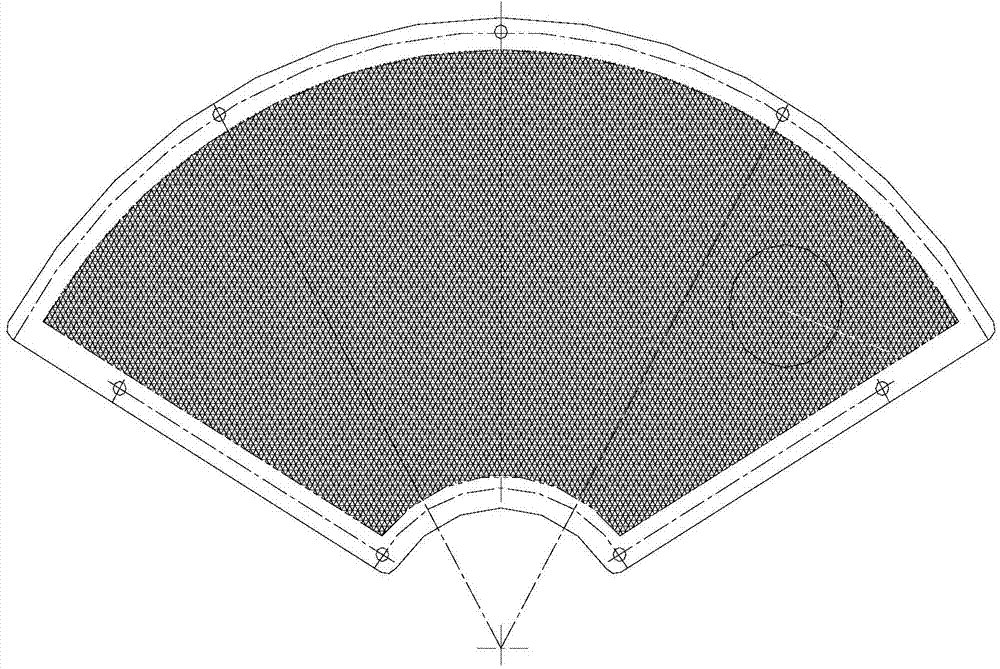

[0032] (1) Determine the parameters of the self-reflecting cube array according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com