Preparation method of high capacitance polyaniline and nickel oxide composite electrode material

A composite electrode, polyaniline technology, used in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of inability to achieve mass production, expensive raw materials, low specific capacitance of capacitors, etc., and achieve good cyclic voltammetry performance, high purity, device simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

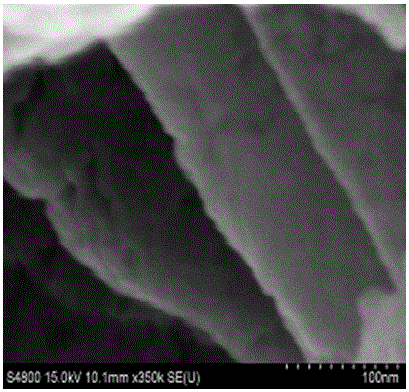

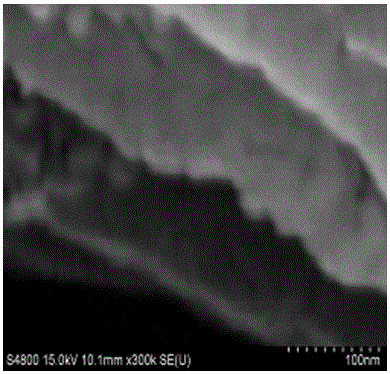

Image

Examples

Embodiment Construction

[0015] 1. Preparation process:

[0016] According to a certain mass ratio of substances, after mixing anionic and cationic surfactants with C6-C8 alcohols to form lyotropic liquid crystals, sulfuric acid-doped aniline and a certain concentration of nickel sulfate solution are respectively dissolved in the lyotropic liquid crystals. The nickel sheet is used as an electrode, and a potential of 0.75-0.90V is applied to electrodeposit a composite material of polyaniline and metal nickel with a certain structure and morphology. The obtained composite material was oxidized in high-purity oxygen to obtain a composite electrode material.

[0017] Electrode materials with the same effect can also be obtained by using the following five different proportioning schemes.

[0018] Scheme 1: Total 51.9% of dodecyltrimethylammonium sulfide and sodium dodecylsulfonate (feeding mass ratio is 1:1), 34.6% of n-hexanol, 1.1% of sulfuric acid, 0.62% of aniline, and 0.6% of nickel sulfate %, deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com