UV curing anti-cracking oil composition

An oil composition, ultraviolet light technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as the difficulty of high-density boards, can not meet the requirements of mechanical properties of high-density boards, etc., to improve the adhesion level, mechanical properties, etc. Excellent performance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

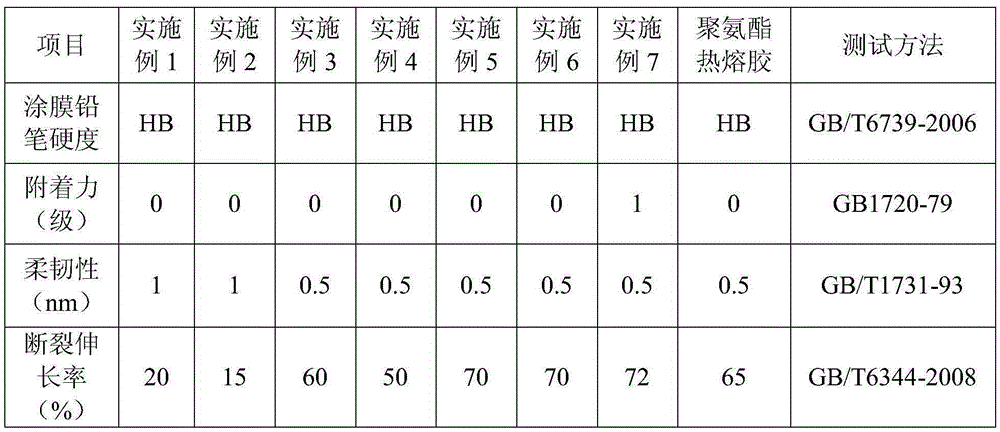

Examples

Embodiment 1

[0028] Get 55 grams of polyurethane acrylate (product of Sartomer, USA, No. CN965), 25 grams of propoxylated neopentyl glycol diacrylate, 10 grams of hydroxypropyl acrylate, 2 grams of 1-hydroxycyclohexyl phenyl ketone, 2 grams of 2, 4. 6-trimethylbenzoyl phosphine oxide, 3 grams of pentaerythritol tetrakis (3-mercaptopropionate) ester, 3 grams of acrylate phosphate, stirred and mixed evenly.

Embodiment 2

[0030] Take 55 grams of polyurethane acrylate (product of Taiwan Changxing Company, No. EM6112), 25 grams of propoxylated neopentyl glycol diacrylate, 10 grams of hydroxypropyl acrylate, 2 grams of 1-hydroxycyclohexyl phenyl ketone, 2 grams of 2, 4. 6-trimethylbenzoyl phosphine oxide, 3 grams of pentaerythritol tetrakis (3-mercaptopropionate) ester, 3 grams of acrylate phosphate, stirred and mixed evenly.

Embodiment 3

[0032] Take 55 grams of polyurethane acrylate (product of Hunan Xinlitai New Material Co., Ltd., No. TY-115, prepared from tetrahydrofuran homopolyether, toluene diisocyanate and hydroxyethyl acrylate), 25 grams of propoxylated neopentyl diacrylate Alcohol diacrylate, 10 g hydroxyethyl acrylate, 2 g 1-hydroxycyclohexyl phenyl ketone, 2 g 2,4,6-trimethylbenzoylphosphine oxide, 3 g pentaerythritol tetrakis(3-mercaptopropionic acid ) ester, 3 grams of acrylate phosphate, stir and mix well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com