A neutral electric Fenton oxidation water treatment method coupled with molecular oxygen activation

A technology for oxidizing water and treatment methods, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as corroding equipment, increasing wastewater treatment costs, and being unfavorable for wastewater discharge, etc. Achieve the effects of not easy to decompose, simplify the subsequent treatment process, and improve the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

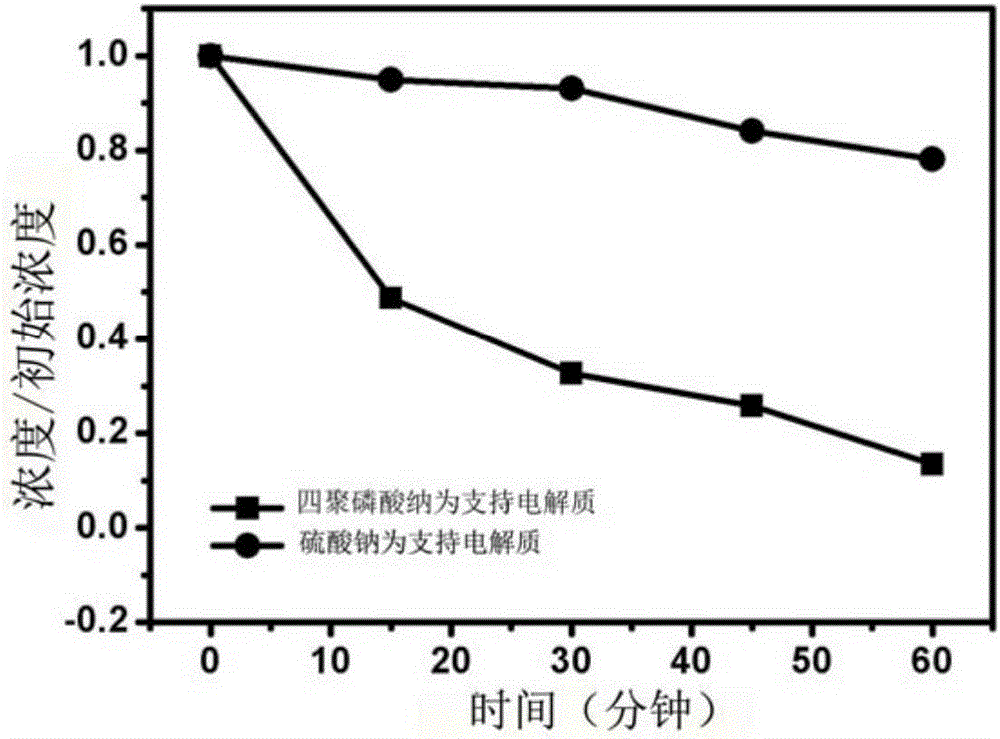

[0033] Embodiment 1 controls the sewage containing dye Rhodamine B

[0034] For the electro-Fenton restoration of dye-contaminated water sources, this example uses the self-prepared rhodamine B aqueous solution as the experimental object to carry out the high-efficiency neutral electro-Fenton treatment experiment coupled with the activation of molecular oxygen.

[0035] The rhodamine B aqueous solution with a concentration of 10mg / L was used as the simulated wastewater, and the pH value of the rhodamine B aqueous solution was 6.6 (no need to add acid and alkali to adjust the pH). Take 25mL of simulated wastewater, and add sodium tetrapolyphosphate to it to make the concentration 0.3mmol / L. Using iron wire as the anode and activated carbon fiber as the cathode, the constant current is 0.6mA, the anode current density is 6 amps / square meter, air is blown into the cathode through the aeration device, and the air flow rate is 40mL / min, and the simulated wastewater is subjected to ...

Embodiment 2

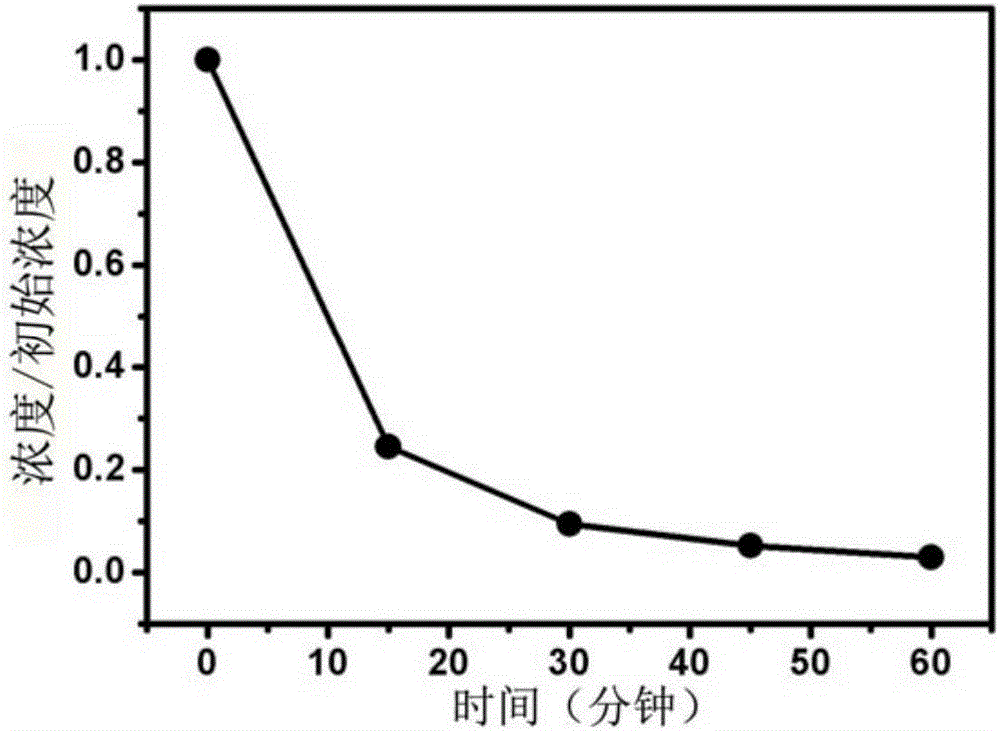

[0037] Embodiment 2 controls the sewage containing pesticide atrazine

[0038] For the electro-Fenton restoration of pesticide-contaminated water sources, this example uses the self-prepared atrazine aqueous solution as the experimental object to conduct an efficient neutral electro-Fenton treatment experiment coupled with molecular oxygen activation.

[0039]The atrazine aqueous solution with a concentration of 15mg / L was used as the simulated wastewater, and the pH value of the atrazine aqueous solution was 6.8 (no need to add acid and alkali to adjust the pH). Take 25mL of simulated wastewater, and add sodium tripolyphosphate to it to make the concentration 0.5mmol / L. Using iron wire as the anode and activated carbon fiber as the cathode, the constant current is 0.5mA, the anode current density is 5 amps / square meter, air is blown into the cathode through the aeration device, and the air flow rate is 60mL / min, and the simulated wastewater is subjected to electro-Fenton oxid...

Embodiment 3

[0040] Example 3 Treatment of sewage containing pesticide atrazine under different pH conditions

[0041] In this example, the self-prepared atrazine aqueous solution was used as the experimental object to carry out the high-efficiency neutral electric Fenton treatment experiment coupled with the activation of molecular oxygen.

[0042] Take the atrazine aqueous solution with a concentration of 15mg / L as the simulated wastewater, add sodium tetrapolyphosphate to it at a concentration of 0.5mmol / L, and adjust the initial pH of the solution with NaOH or HCl solution to be 5.3, 6.3, 7.3, 8.3 respectively , 9.3. Take 25mL of simulated wastewater with different initial pH, use iron wire as anode, activated carbon fiber as cathode, constant current 0.5mA, anode current density 5A / square meter, blow air into cathode through aeration device, air flow rate is 60mL / min, the simulated wastewater was subjected to electro-Fenton oxidation treatment. like image 3 As shown, after electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com