A method of adding ammonium citrate to prepare nanoscale yttrium aluminum garnet powder

A technology of yttrium aluminum garnet and ammonium citrate, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of uneven grain size distribution of YAG powder, hinder the application of sol-gel method, and cause china Uneven density and other problems, to achieve the effect of uniform grain size distribution, uniform density, and easy uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the preparation method of nanoscale yttrium aluminum garnet powder is as follows:

[0032] (1) Preparation of raw material mixture

[0033] Weigh 0.015mol Y(NO 3 ) 3 ·6H 2 O, 0.025mol Al(NO 3 ) 3 9H 2 O, 0.04mol anhydrous citric acid (C 6 h 8 o 7 ) and 0.04mol ammonium citrate (C 6 h 17 N 3 o 7 ), they were added to 200mL of absolute ethanol and mixed evenly to form a raw material mixture.

[0034] (2) Preparation of sols and gels

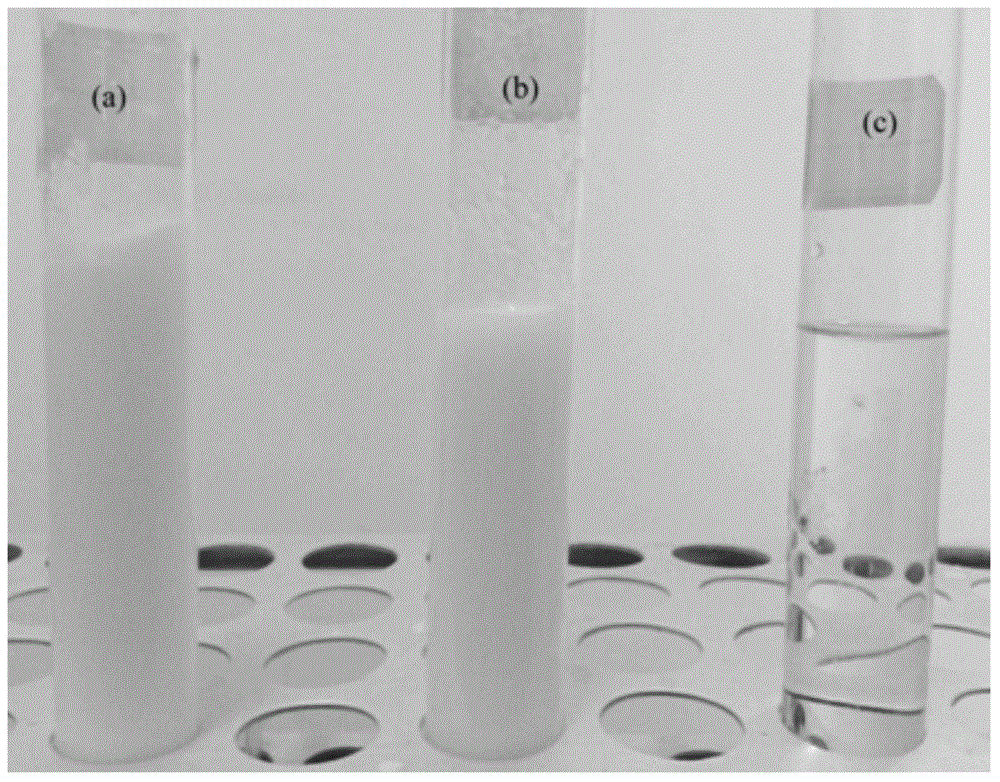

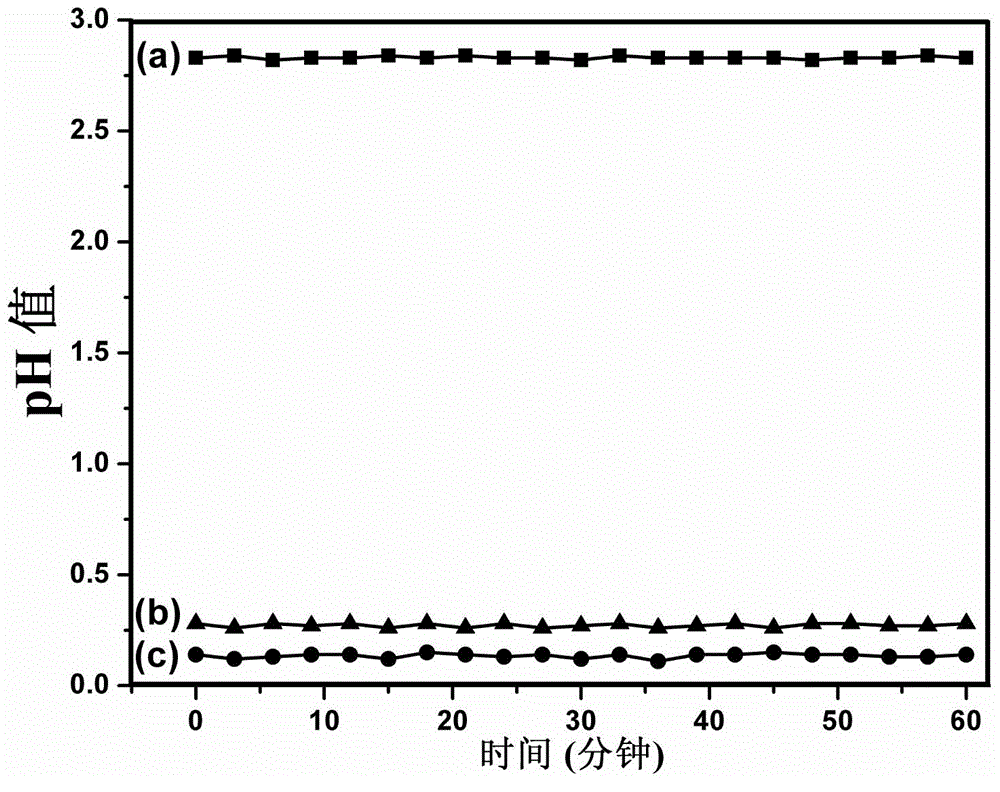

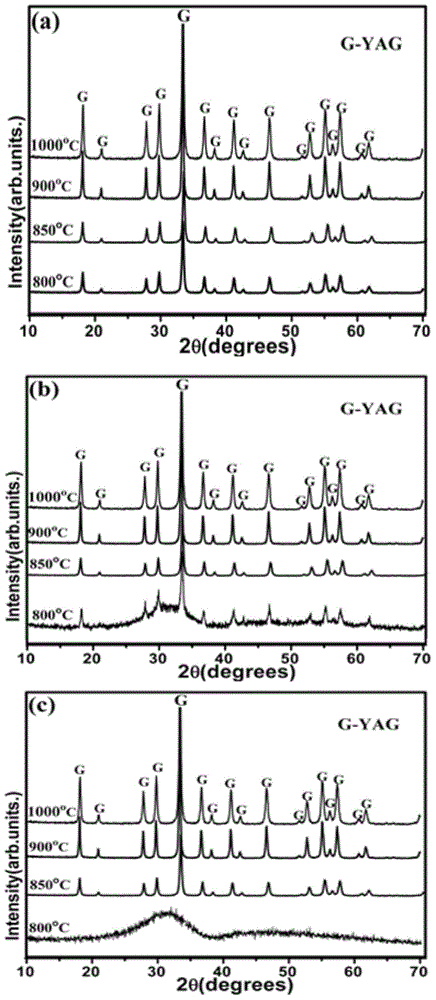

[0035] Heat the raw material mixture to 60°C at a stirring speed of 100rpm and keep stirring at this temperature, so that the raw material mixture turns into a white slurry, see figure 1 (a), the probe of the pH meter is placed in the white slurry to test the change of pH value of the white slurry for 1h thereafter (read the pH value once every 3min), and the test results are as follows figure 2 As shown in (a), the white slurry finally turned into a sol under stirring conditions, and then the resulting sol ...

Embodiment 2

[0061] In this embodiment, the preparation method of nanoscale yttrium aluminum garnet powder is as follows:

[0062] (1) Preparation of raw material mixture

[0063] Weigh 0.03mol YCl 3 ·6H 2 O, 0.05mol AlCl 3 ·6H 2 O, 0.08mol anhydrous citric acid (C 6 h 8 o 7 ) and 0.12mol ammonium citrate (C 6 h 17 N 3 o 7 ), they were added to 320mL of absolute ethanol and mixed evenly to form a raw material mixture.

[0064] (2) Preparation of sols and gels

[0065] The raw material mixture was heated to 60°C at a stirring speed of 90rpm and kept at this temperature to continue stirring, so that the raw material mixture was transformed into a white slurry, and continued stirring was used to transform the white slurry into a sol. Heating to 100°C under stirring speed and maintaining the temperature to continue stirring to transform the sol into a transparent gel.

[0066] (3) Roasting

[0067] The transparent gel was heated to 160°C and kept at this temperature until no smok...

Embodiment 3

[0069] In this embodiment, the preparation method of nanoscale yttrium aluminum garnet powder is as follows:

[0070] (1) Preparation of raw material mixture

[0071] Weigh 0.045mol Y(NO 3 ) 3 ·6H 2 O, 0.075mol Al(NO 3 ) 3 9H 2 O, 0.12mol anhydrous citric acid (C 6 h 8 o 7 ) and 0.216mol ammonium citrate (C 6 h 17 N 3 o 7 ), they were added to 720mL of absolute ethanol and mixed evenly to form a raw material mixture.

[0072] (2) Preparation of sols and gels

[0073] The raw material mixture was heated to 70°C at a stirring speed of 110rpm and kept at this temperature to continue stirring, so that the raw material mixture was transformed into a white slurry, and continued stirring was used to transform the white slurry into a sol, and then the resulting sol was mixed at 110rpm Heat to 110° C. under stirring speed and keep stirring at this temperature to transform the sol into a transparent gel.

[0074] (3) Roasting

[0075] The transparent gel was heated to 18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com