Oxidation catalyst for diesel engine exhaust

An oxidation catalyst and diesel engine technology, applied in physical/chemical process catalysts, molecular sieve catalysts, catalyst activation/preparation, etc., can solve the problems of increasing the cost of diesel engine exhaust treatment, cumbersome catalyst devices, catalyst pressure drop, etc., and achieve post-treatment exhaust gas treatment. , The effect of improving sulfur resistance and reducing combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 prepares catalyst carrier

[0037] Put the cordierite honeycomb ceramics in an ultrasonic instrument for cleaning, add hydrofluoric acid during the cleaning process and adjust the pH to 2, the frequency is 50HZ, the power is 100W, and the ultrasonic cleaning time is 200min to obtain a catalyst carrier with a cleaner pore wall .

Embodiment 2

[0038] Embodiment 2 prepares catalyst carrier

[0039] Put the cordierite honeycomb ceramics in an ultrasonic instrument for cleaning, add hydrofluoric acid during the cleaning process and adjust the pH to 1, the frequency is 50HZ, the power is 100W, and the ultrasonic cleaning time is 400min to obtain a catalyst carrier with a cleaner pore wall .

Embodiment 3

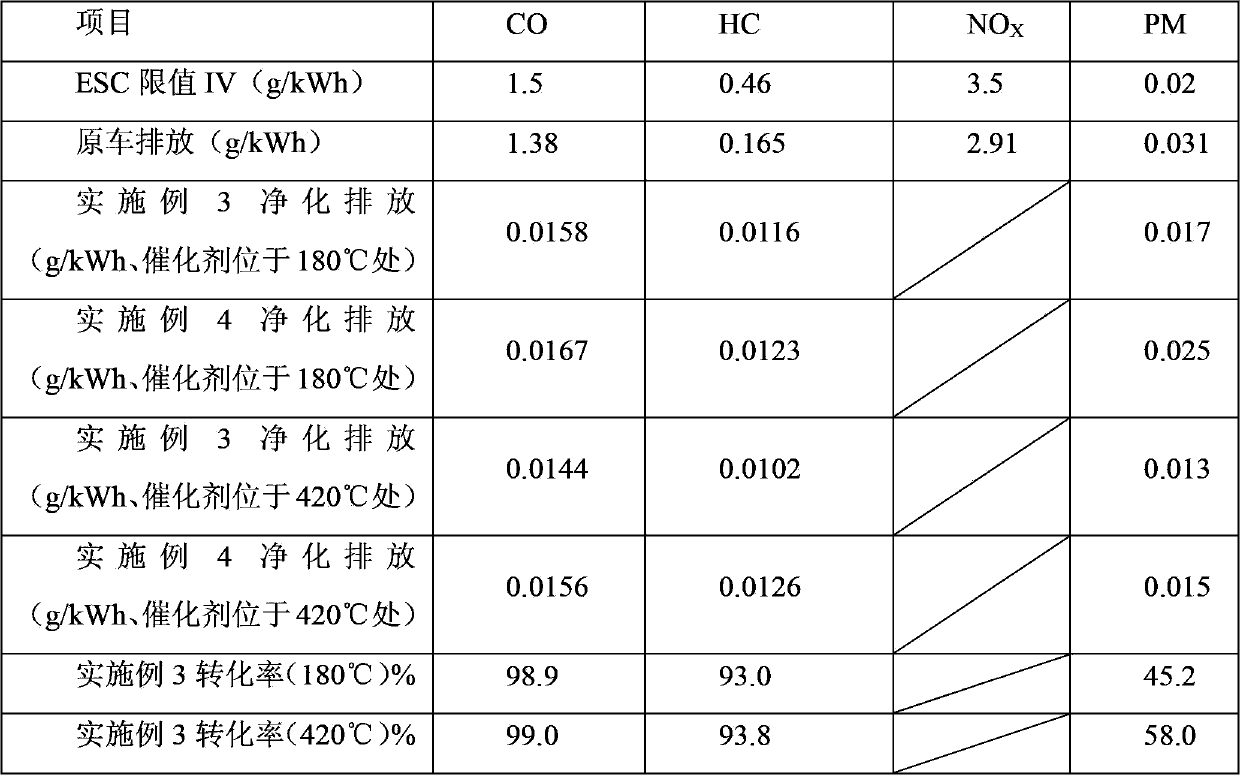

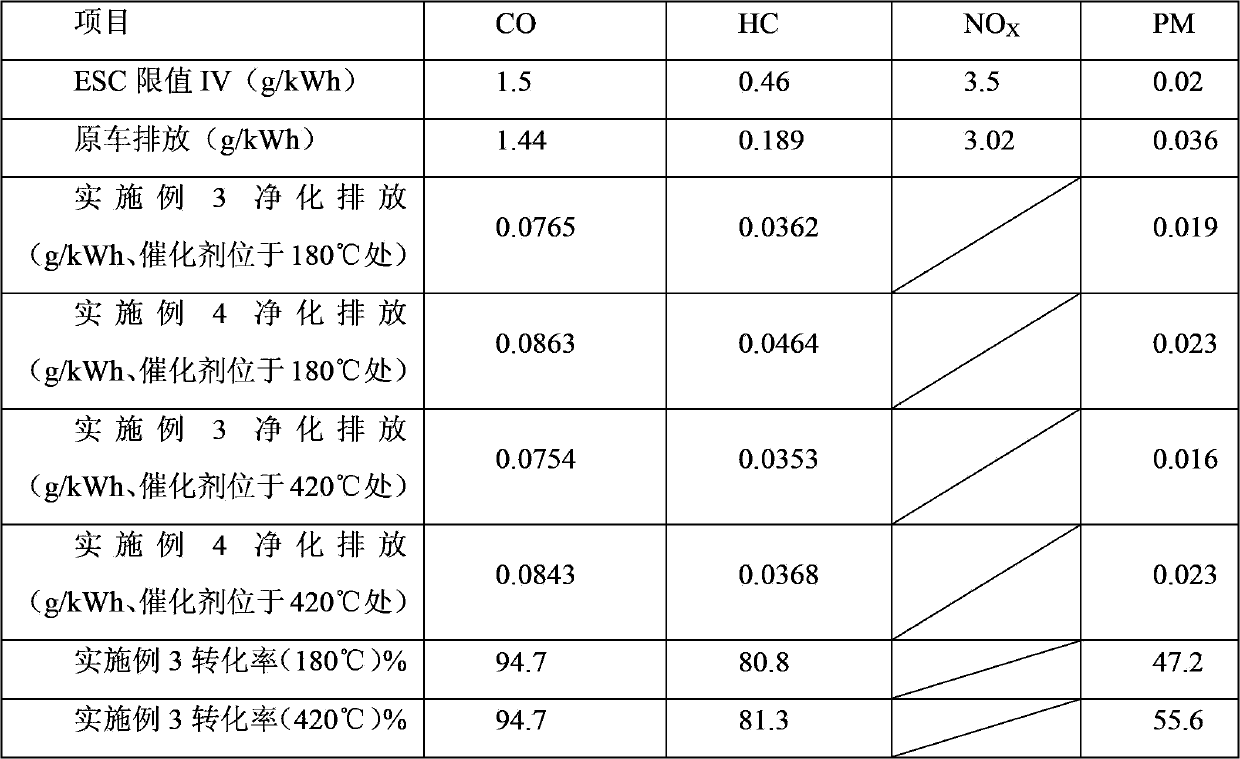

[0040] Embodiment 3 Preparation of Diesel Engine Exhaust Oxidation Catalyst

[0041] Preparation of modified powder: Simultaneously modify γ-alumina with silica, titania precursor silica sol, and n-butyl titanate at a temperature of 150°C and a pressure of 10 MPa, in which silica, titania and The mass ratio of γ-alumina is 28:26:46;

[0042] Preparation of modified molecular sieves: modifying molecular sieves with a platinum nitrate solution with a mass concentration of 10%; wherein the weight ratio of platinum simple substance to molecular sieves in the platinum nitrate solution is 1:30; the silicon-aluminum molar ratio of the molecular sieves is 150;

[0043] Mix the modified powder, modified molecular sieve, polyvinyl alcohol and water according to the mass ratio of 45:30:1:80, carry out high-speed shear emulsification, and the shear speed is 150r / min, so as to obtain the coating colloid;

[0044] The coating colloid is added in the ammonium humate to age, the addition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com