Electrochemical power supply diaphragm, preparation method thereof and electrochemical power supply

An electrochemical and power supply technology, applied in the field of electrochemical power supply, can solve the problems of excessive pores, self-discharge, uneven distribution, etc., and achieve the effects of low equipment requirements, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

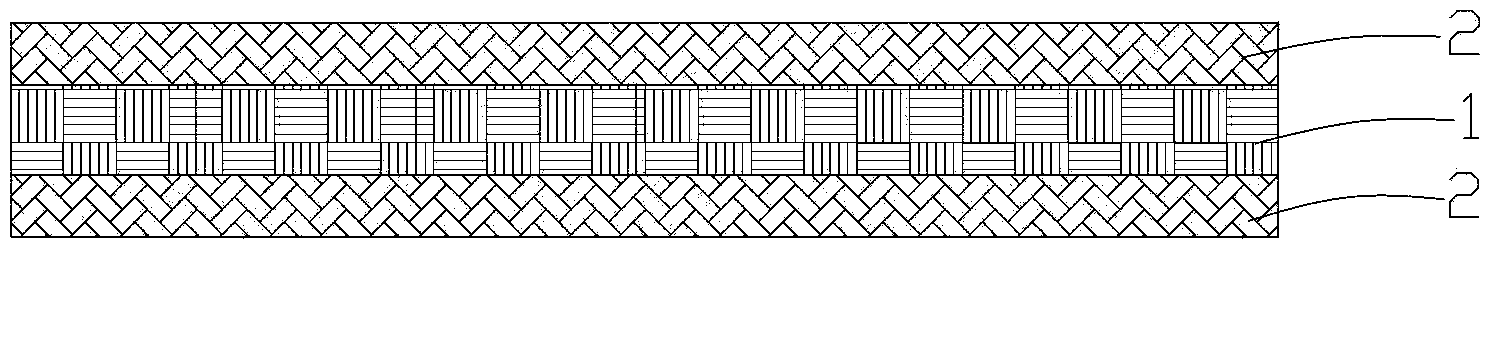

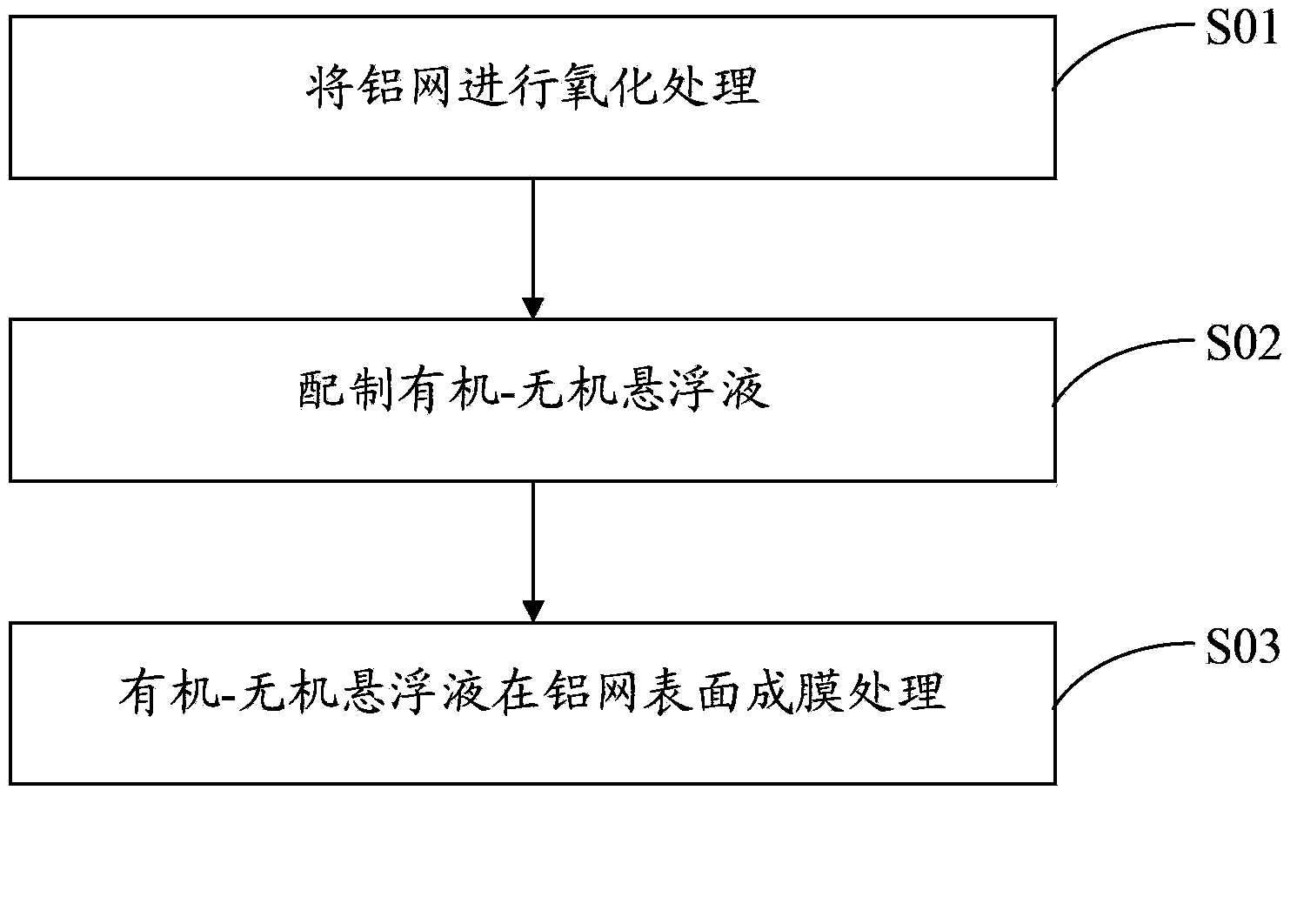

[0028] Correspondingly, the embodiment of the present invention also provides a method for preparing the above-mentioned electrochemical power separator, the process flow chart of the method is as follows figure 2 shown, see also figure 1 . This preparation method comprises the steps:

[0029] Step S01. Oxidizing the aluminum mesh;

[0030] Step S02. Prepare an organic-inorganic suspension: dissolve the organic binder in an organic solvent and add inorganic powder to prepare a suspension;

[0031] Step S03. Film-forming treatment of the organic-inorganic suspension on the surface of the aluminum mesh: coating the suspension prepared in step S02 on the surface of the aluminum mesh and drying to obtain the electrochemical power separator.

[0032] Specifically, in the above-mentioned step S01, the oxidation treatment of the aluminum mesh is preferably performed as follows: the aluminum mesh is placed in an oxidizing atmosphere and oxidized at 200-650° C. for 0.5-24 hours.

...

Embodiment 1

[0044] A battery diaphragm, a preparation method thereof and a lithium ion battery, the preparation method of the battery diaphragm comprises the following steps:

[0045] S11: placing an aluminum mesh with a thickness of 20 microns and a pore size of 20 microns in a muffle furnace at 500° C. for 6 hours, and taking out the oxidized aluminum mesh after cooling;

[0046] S12: Add 40 parts by weight of polytetrafluoroethylene to the container containing acetone, and keep stirring until it is completely dissolved to form an organic solution, and then add 10 parts by weight of hollow oxide polytetrafluoroethylene with an average particle diameter of 500 nanometers to the organic solution. aluminum powder, and stir evenly to obtain an organic-inorganic suspension, wherein the mass percent concentration of the hollow alumina powder in the organic-inorganic suspension is 10%;

[0047] S13: Immerse the oxidized aluminum mesh into the organic-inorganic suspension prepared in step S12, ...

Embodiment 2

[0051] A battery diaphragm, a preparation method thereof and a lithium ion battery, the preparation method of the battery diaphragm comprises the following steps:

[0052] S21: placing an aluminum mesh with a thickness of 25 microns and a pore size of 10 microns in a muffle furnace at 400° C. for 12 hours, and taking out the oxidized aluminum mesh after cooling;

[0053] S22: Add 50 parts by weight of polytetrafluoroethylene into a container containing 2 parts of acetone, and keep stirring until it is completely dissolved to form an organic solution, and then add 25 parts by weight of hollow polytetrafluoroethylene with an average particle diameter of 200 nanometers to the organic solution. Silica powder, and stir evenly, obtain organic-inorganic suspension; Wherein, the mass percent concentration of hollow silica powder in organic-inorganic suspension is 25%;

[0054] S23: Immerse the oxidized aluminum mesh into the organic-inorganic suspension prepared in step S22, and keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com