Perovskite solar battery and preparing method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of high production costs, low energy conversion efficiency, and bottlenecks in the development of solar cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

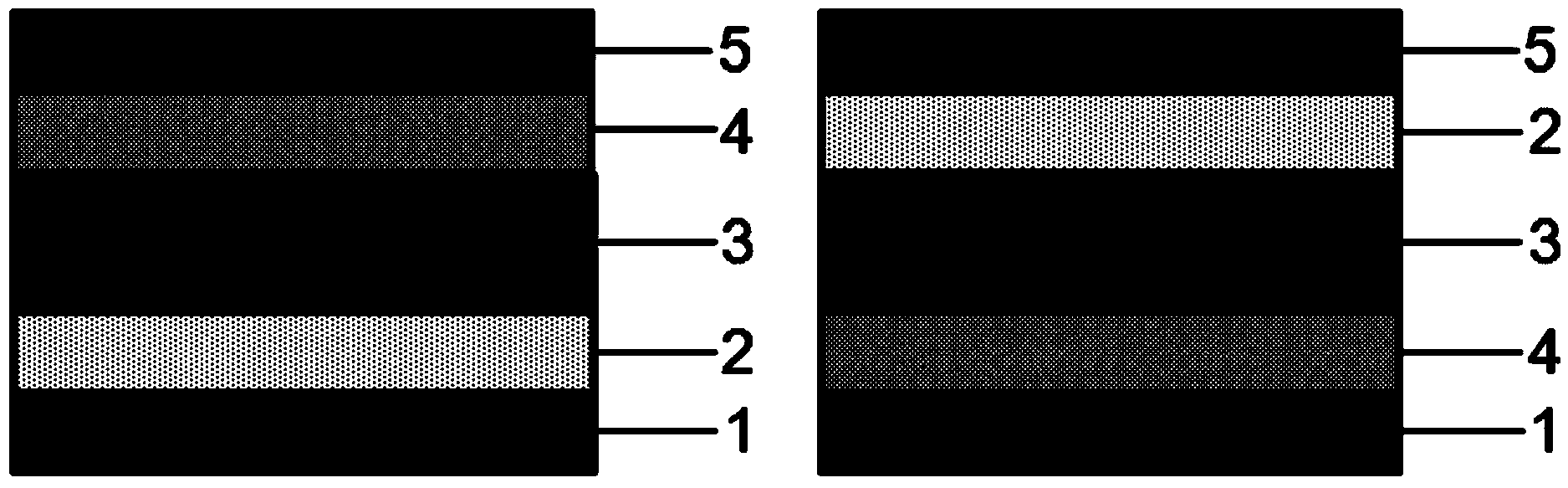

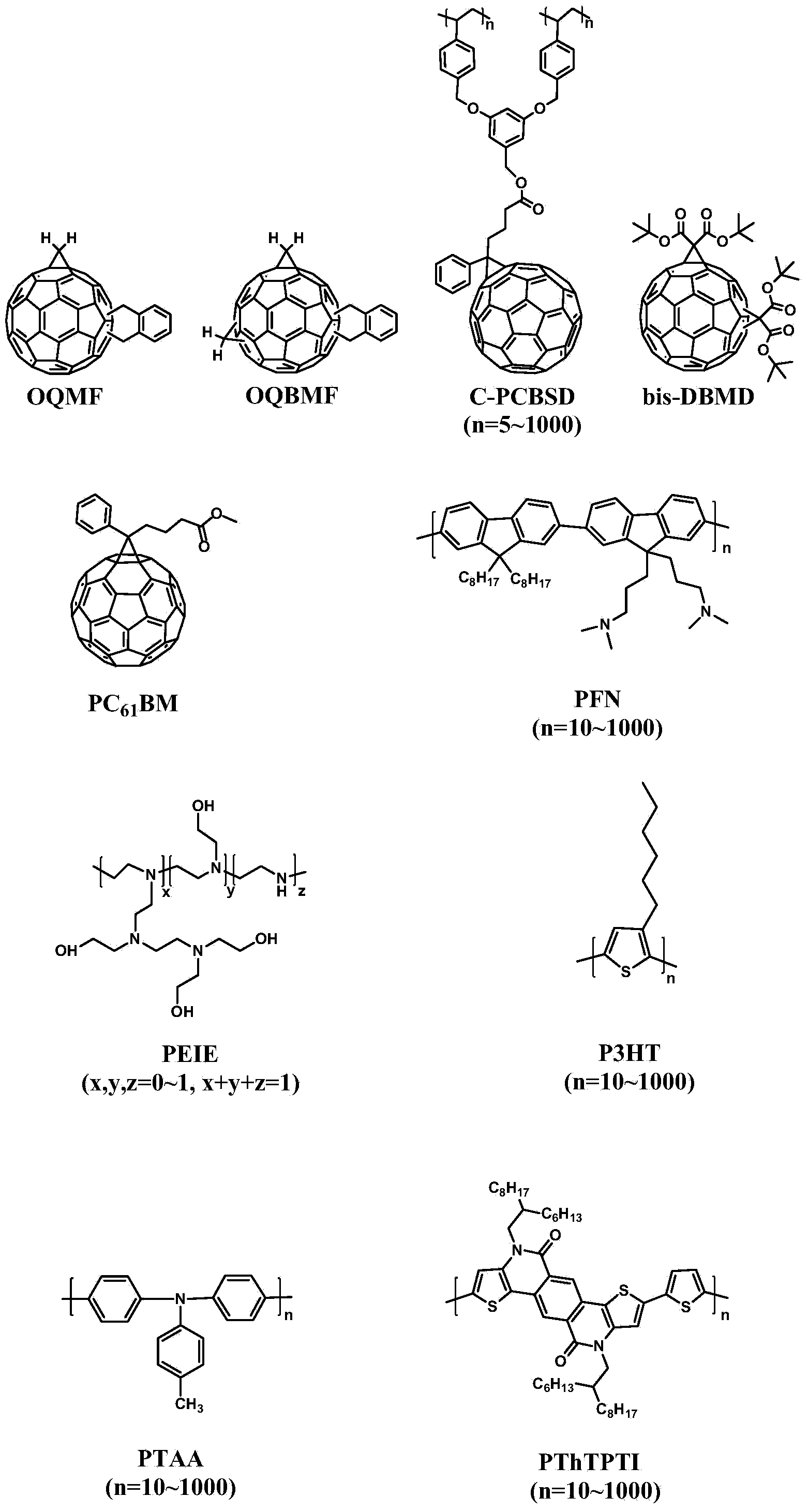

[0045] Preparation of ITO / PEDOT:PSS / CH 3 NH 3 PB 3-x Cl x / OQBMF / Al perovskite solar cell

[0046] First PEDOT:PSS (Clevios TM P VP AI4083) was spin-coated on the pretreated ITO glass surface at a speed of 2500rpm, and heated at 100°C in air for 50min to obtain a 50nm thick PEDOT:PSS film; a molar ratio of 3:1 CH 3 NH 3 I and PbCl 2 Mix and dissolve in DMF to obtain a solution with a concentration of 51wt%, spin-coat it on the PEDOT:PSS film at a speed of 4500rpm in a glove box, heat at 140°C for 30min, and obtain a 230nm brown-black CH 3 NH 3 PB 3-x Cl x Thin film; OQBMF was dissolved in chlorobenzene or other solvents to obtain a solution with a concentration of 30mg / mL, which was spin-coated on CH at 4000rpm 3 NH 3 PB 3-x Cl x On the film, a 57nm OQBMF film was obtained; in high vacuum (-4 Pa), vapor-deposit 100nm aluminum electrode to complete the battery preparation. After testing, the battery efficiency is 12.5%.

Embodiment 2

[0048] Preparation of ITO / PEDOT:PSS / CH 3 NH 3 PB 3-x Cl x / PC 61 BM / Al perovskite solar cells

[0049] First PEDOT:PSS (Clevios TM P VP AI4083) was spin-coated on the pretreated ITO glass surface at 2000rpm, and heated at 120°C in air for 30min to obtain a 57nm thick PEDOT:PSS film; the molar ratio was 3.2:1 CH 3 NH 3 I and PbCl 2 Mix and dissolve in DMF to obtain a solution with a concentration of 40wt%, spin-coat it on the PEDOT:PSS film at a speed of 1000rpm in a glove box, heat at 120°C for 45min, and obtain a 460nm brown-black CH 3 NH 3 PB 3-x Cl x film; the PC 61 BM was dissolved in chlorobenzene or other solvents to obtain a solution with a concentration of 20mg / mL, which was spin-coated on CH at 1500rpm 3 NH 3 PB 3-x Cl x thin film, resulting in 40nm PC 61 BM film; in high vacuum (-4 Pa), vapor-deposit 100nm aluminum electrode to complete the battery preparation. After testing, the battery efficiency is 10.8%.

Embodiment 3

[0051] Preparation of ITO / PEDOT:PSS / CH 3 NH 3 PB 3-x Cl x / PC 61 BM / Al perovskite solar cells

[0052] First PEDOT:PSS (Clevios TM P VP AI4083) was spin-coated on the pretreated ITO glass surface at a speed of 3000rpm, and heated at 160°C in the air for 25min to obtain a 41nm thick PEDOT:PSS film; the molar ratio of CH was 3.1:1 3 NH 3 I and PbCl 2 Mix and dissolve in DMF to obtain a solution with a concentration of 45wt%, spin-coat it on the PEDOT:PSS film at 2000rpm in a glove box, heat at 115°C for 80min, and obtain a 360nm brown-black CH 3 NH 3 PB 3-x Cl x film; the PC 61 BM was dissolved in chlorobenzene or other solvents to obtain a solution with a concentration of 10mg / mL, which was spin-coated on CH at 800rpm 3 NH 3 PB 3-x Cl x thin film, to obtain 45nm PC 61 BM film; in high vacuum (-4 Pa), vapor-deposit a 150nm aluminum electrode to complete the battery preparation. After testing, the battery efficiency is 11.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com