chain drive

A technology of chain transmission and chain, which is applied in the direction of transmission device, transmission chain, belt/chain/gear, etc. It can solve the problems of increased power loss, increased friction of guide block, unstable chain, etc., and achieves the effect of reducing sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

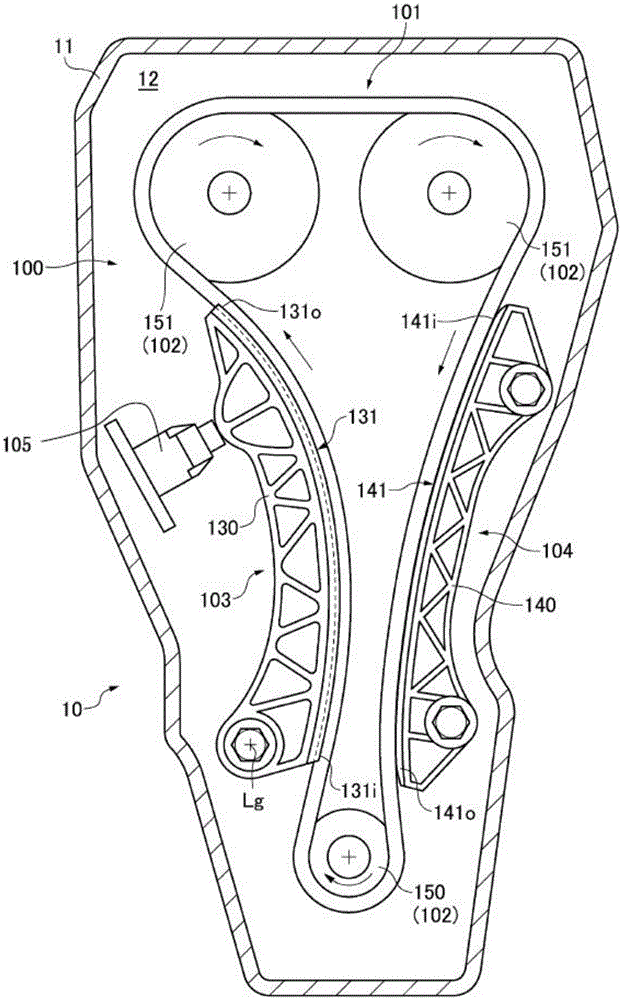

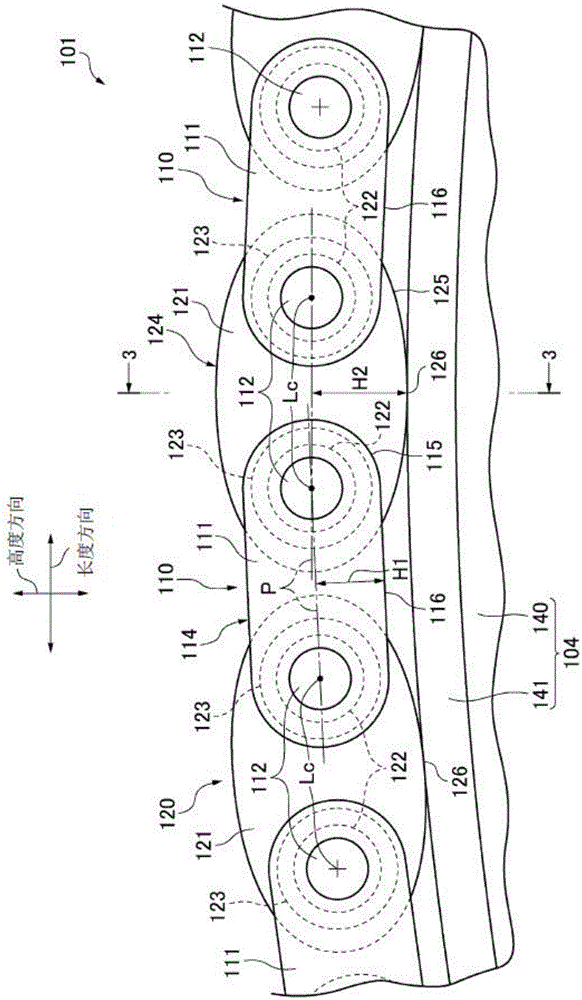

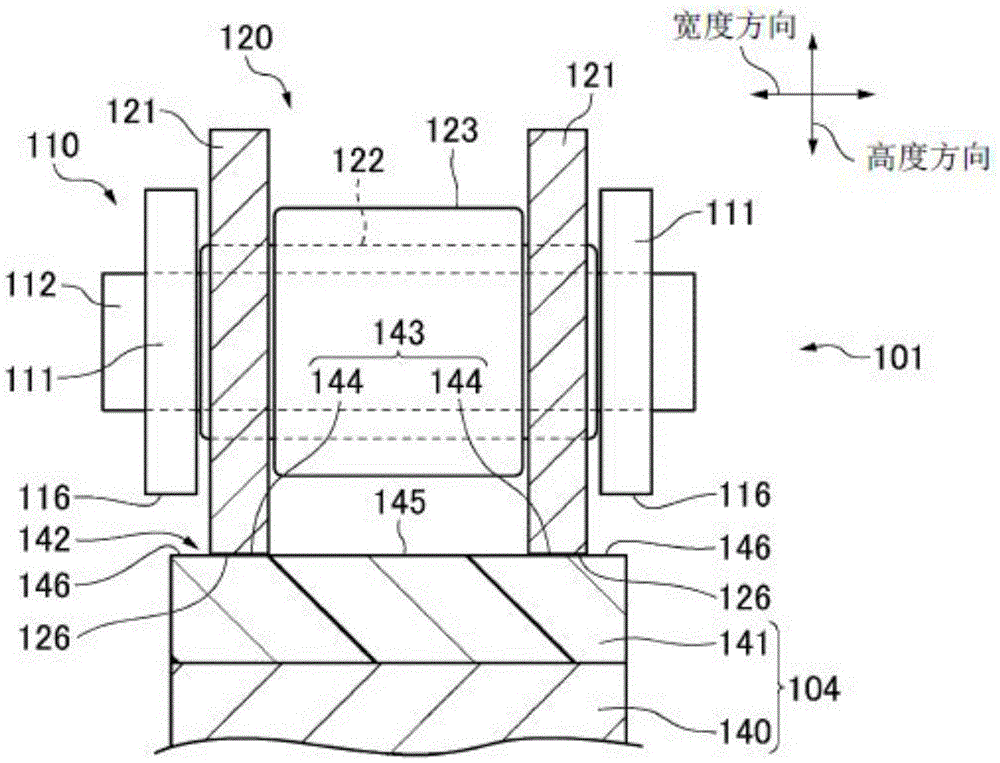

[0045] Below, refer to Figure 1 to Figure 8 Examples of the present invention will be described.

[0046] Figure 1 ~ Figure 4 It is a figure for explaining the 1st Example of this invention.

[0047] when referring to figure 1 In the first embodiment, the chain transmission device 100 is included in the motor vehicle engine 10 as a machine. Furthermore, the chain transmission 100 is a timing chain transmission for driving a valve train of the engine 10 .

[0048] The chain transmission device 100 has: a chain 101, which is a roller chain; a sprocket group 102, which is formed by a plurality of sprockets 150, 151 passed by the chain 101; a movable guide 103, a fixed guide 104, which are in sliding contact The chain 101 in the moving state is used to guide the moving chain 101 driven by the sprocket group 102 ; and the tensioning device 105 is used to apply tension to the chain 101 through the movable guide 103 .

[0049] The chain transmission device 100 is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com