Process for achieving puncture resistance security upgrade of car wheel

A technology of safety upgrade and process method, applied in the field of automobile wheel puncture resistance safety upgrade, can solve the problems of inconvenience, lack of automobile wheel tire explosion-proof performance, softness, poor ride comfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

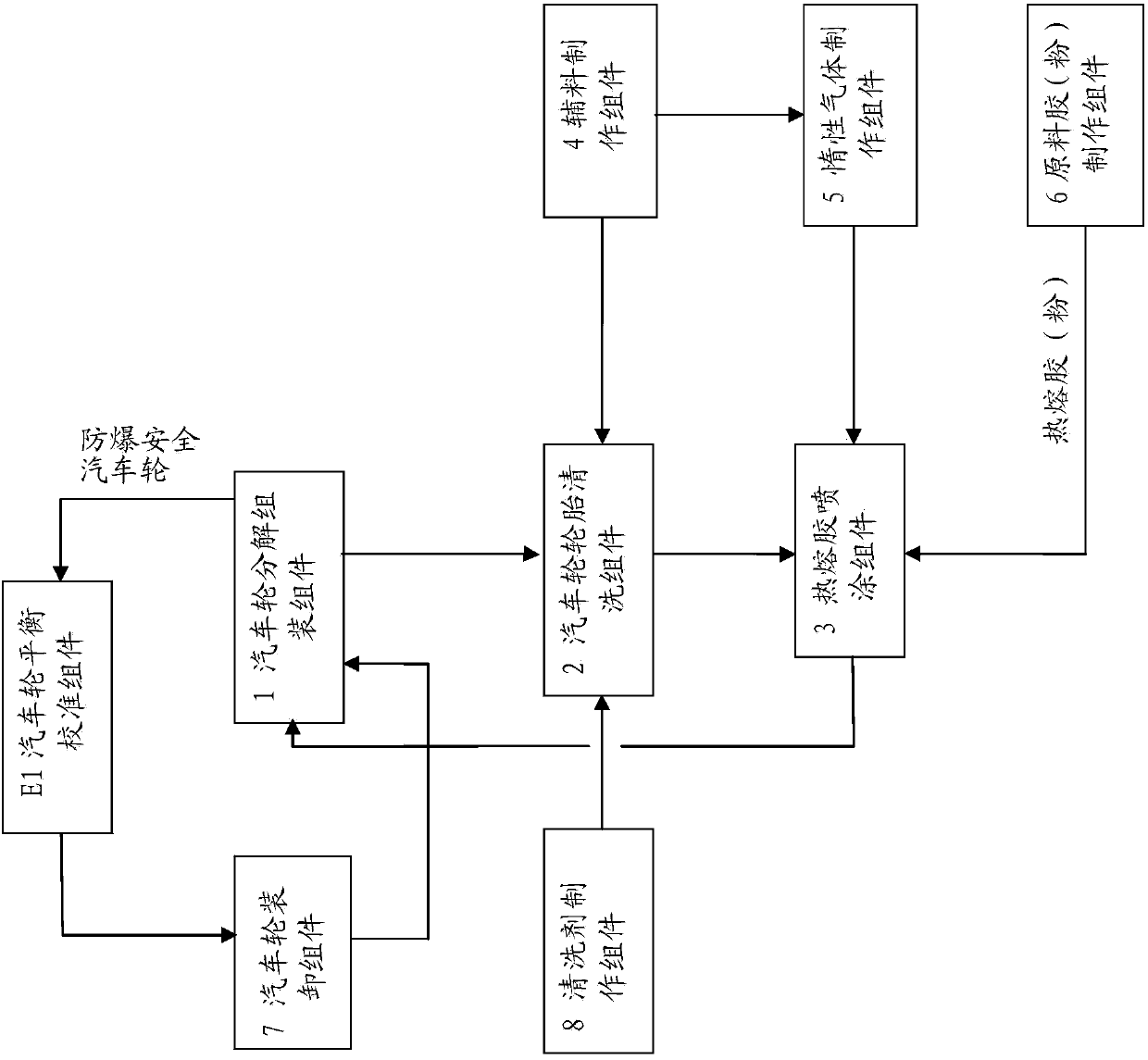

Image

Examples

Embodiment 1

[0049] The composition and weight ratio of the polymer hot-melt self-sealing sealant memory glue used in the process method for safety upgrading of automobile wheel resistance are as follows:

[0050] (1) Thermoplastic elastomer: 45%;

[0051] (2) Tackifier: 41%;

[0052] (3) Softener: 8%;

[0053] (4) Antioxidant: 1%;

[0054] (5) Filler: 5%

[0055] Among them, the thermoplastic elastomer is selected from SIS and SEBS mixture; the tackifier is selected from the mixture of petroleum resin and aromatic hydrocarbon modified terpene resin with the number of carbons being 5 and 9; the antioxidant is selected from the mixture of 2246 and 300; The softener is a mixture of diisobutyl phthalate and dioctyl phthalate.

[0056] The process and steps of safety upgrade of automobile wheel resistance are as follows:

[0057] First, use the air compression component (4), the inert medium production component (5), the raw material production component (6), and the auxiliary material pr...

Embodiment 2

[0069] The composition and weight ratio of the polymer hot-melt self-sealing sealant memory glue used in the process method for safety upgrading of automobile wheel resistance are as follows:

[0070] (1) Thermoplastic elastomer: 50%;

[0071] (2) Tackifier: 42%;

[0072] (3) Softener: 5%;

[0073] (4) Antioxidant: 1%;

[0074] (5) Filler: 2%.

[0075] Among them, the thermoplastic elastomer is selected from SIS; the tackifier is selected from hydrogenated petroleum resin; the antioxidant is selected from the mixture of 1010 and 300; the softener is selected from a mixture of diisobutyl phthalate and dioctyl phthalate.

[0076] The process and steps of safety upgrade of automobile wheel resistance are as follows:

[0077] First, use the air compression component (4), the inert medium production component (5), the raw material production component (6), and the auxiliary material production component (8) to respectively produce compressed air, nitrogen, and raw material powd...

Embodiment 3

[0089] The composition and weight ratio of the polymer hot-melt self-sealing sealant memory glue used in the process method for safety upgrading of automobile wheel resistance are as follows:

[0090] (1) Thermoplastic elastomer: 48%;

[0091] (2) Tackifier: 43.5%;

[0092] (3) Softener: 5%;

[0093] (4) Antiaging agent: 0.5%;

[0094] (5) Filler: 3%

[0095] Among them, the thermoplastic elastomer is selected from SIS and SEBS mixture; the tackifier is selected from hydrogenated petroleum resin; the anti-aging agent is selected from the mixture of RD and 4010; the softener is selected from dioctyl phthalate.

[0096] The process and steps of safety upgrade of automobile wheel resistance are as follows:

[0097] First, use the air compression component (4), the inert medium production component (5), the raw material rubber production component (6), and the auxiliary material production component (8) to make compressed air, nitrogen, and raw material rubber—polymer hot-melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spray thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com