Decompression device and vacuum drying device

A technology of a vacuum drying device and a decompression device, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., and can solve problems such as the inability to completely prevent gas liquefaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

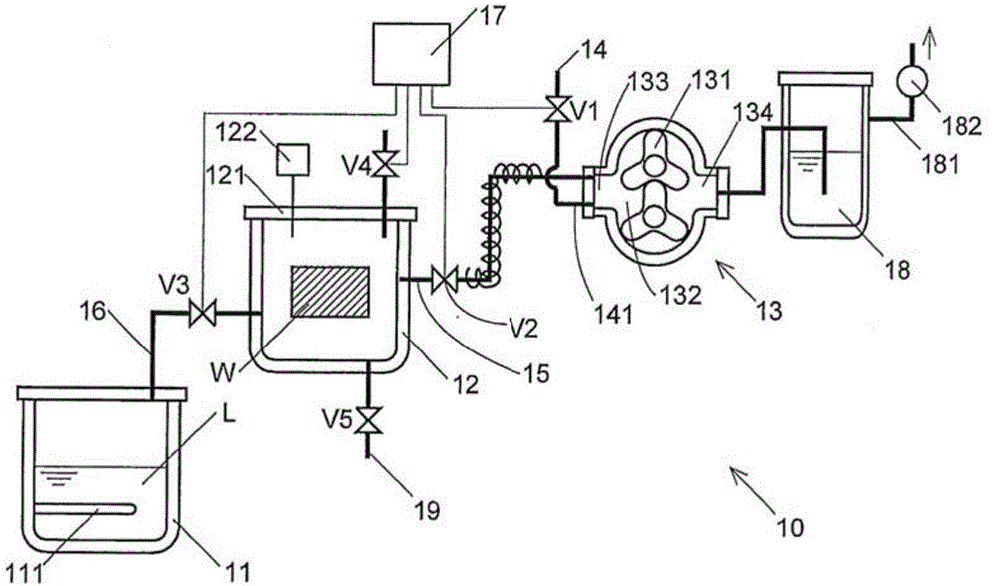

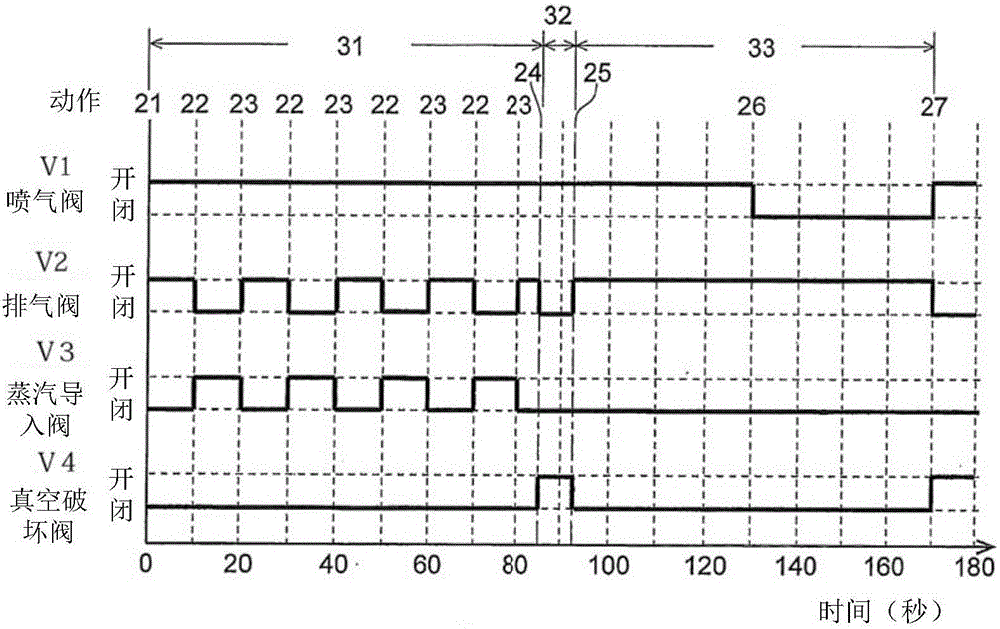

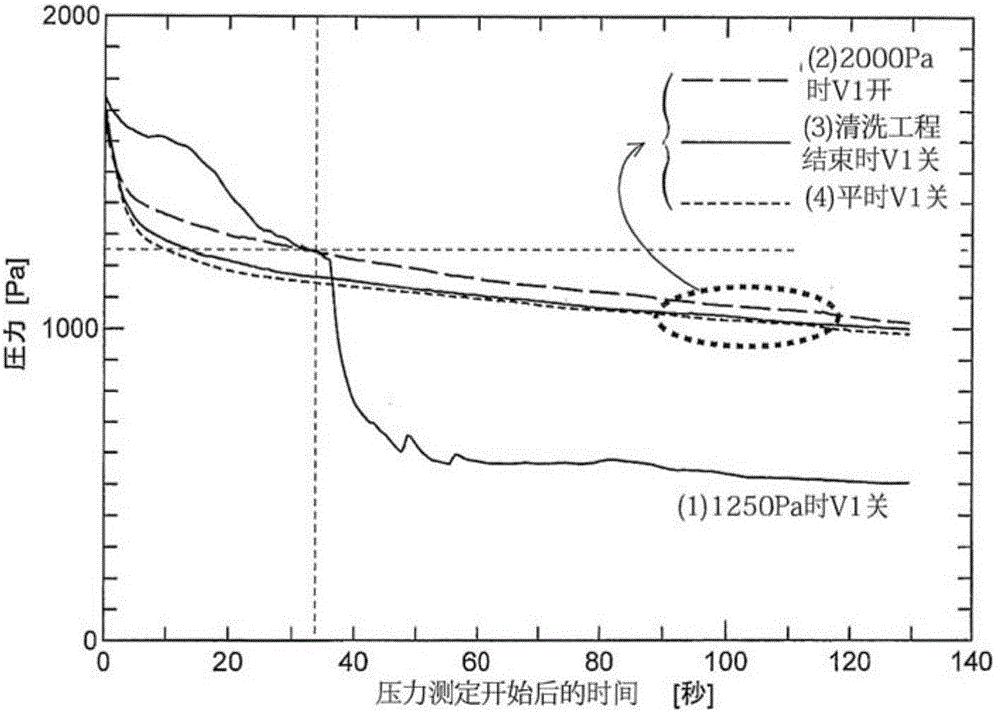

[0034] As a first example, refer to the attached figure 1 ~ attached image 3 , the cleaning and vacuum drying apparatus for vacuum drying the workpiece W after cleaning will be described.

[0035] (1) Configuration of the embodiment.

[0036] Such as figure 1 As shown, a cleaning and vacuum drying device 10 includes a liquid storage tank 11 , a sealing tank 12 , a vacuum pump 13 , and an external air inlet 14 .

[0037] The liquid storage tank 11 is a tank body for storing the cleaning liquid used for cleaning the workpiece W. A heater 111 for heating the cleaning liquid is arranged in the liquid storage tank. The heater 111 heats the cleaning liquid in the liquid storage tank. Until the cleaning solution reaches above the vaporization temperature.

[0038] The sealing tank 12 serves as a tank body for accommodating the workpiece W, and has a capacity of 100L. An open cover 121 is provided in the sealed groove for storing and loading and unloading the workpiece W. In or...

Embodiment 2

[0079] Here, the modification of the cleaning and vacuum drying apparatus in the first embodiment will be described.

[0080] In the first embodiment, although the external air introduction pipe 141 is directly connected to the suction port 133 of the vacuum pump 13, like the attached Figure 4 As shown, the external air introduction pipe 141 may be connected to the exhaust pipe 15 (branched from the exhaust pipe 15 ).

[0081] In addition, in the first embodiment, the embodiment of the cleaning and vacuum drying device for cleaning and vacuum drying the workpiece W in the sealing groove 12 has been described. As a modification of the embodiment, it can be configured that only the workpiece W in the sealing groove 12 W carries out the vacuum drying apparatus 10A of vacuum drying (attached Figure 5 ). The vacuum drying device 10A is composed of the cleaning and vacuum drying device except the liquid storage tank 11, the cleaning liquid heater 111, the steam delivery pipeline...

Embodiment 3

[0084] As the pressure reducing device in the present invention, a degassing device for removing gas dissolved in a liquid can be used. use attached Figure 6 The degasser will be described. The structure of the degassing device 10B is the same as that of the above-mentioned vacuum drying device 10A; in use, the difference from the vacuum device 10A is that the degassed liquid L' is injected into the sealing groove 12 instead of the workpiece W. In addition, the operation of the degassing device 10B is the same as that of the vacuum drying device 10A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com