Method for operating spinning mill installation, and spinning mill installation operated using method

A technology of equipment and feeding equipment, applied in the field of spinning mill equipment, can solve the problems of reduced productivity, inability to use mixing belt adjustment, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

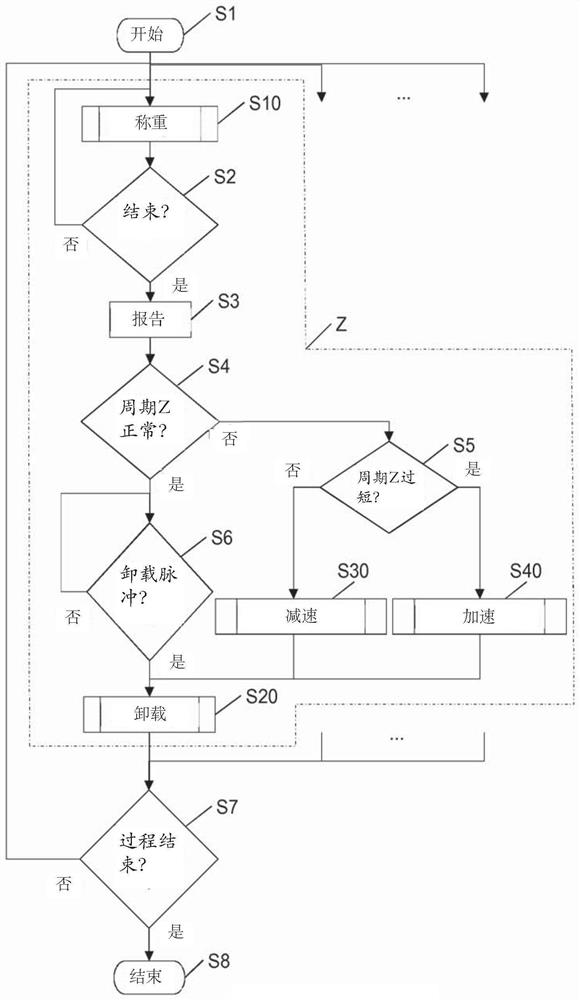

Method used

Image

Examples

Embodiment Construction

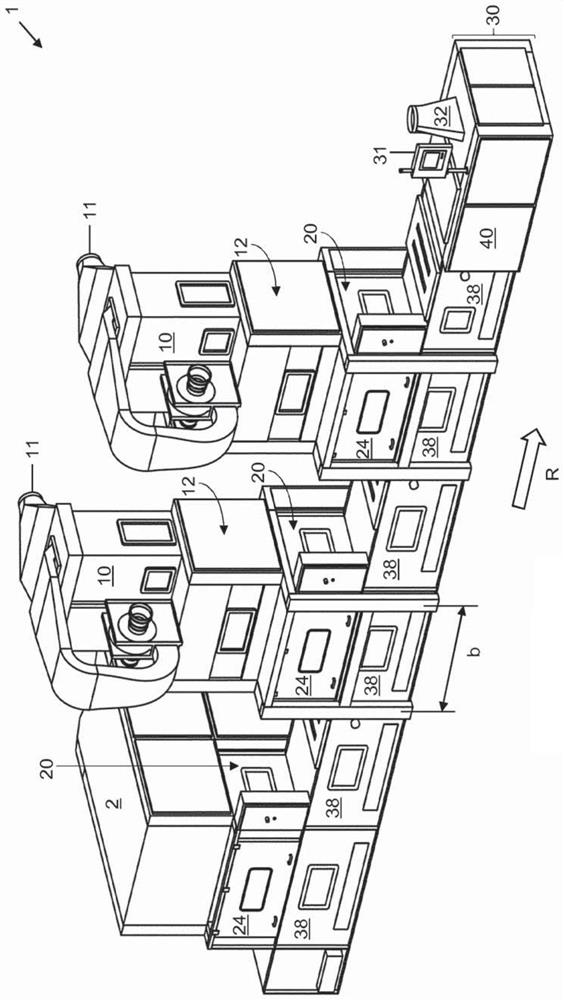

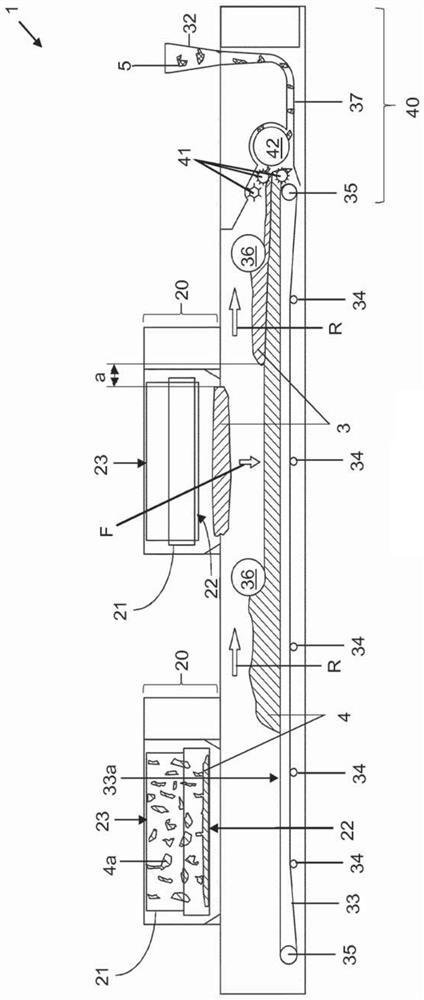

[0034] Figure 1 shows a bulk fiber mixing plant 1 as an example or part of a spinning mill plant.

[0035] according to Figure 1a In the perspective view in FIG. 1, the bulk fiber mixing device 1 includes two feeders 10 in the example shown. Each feeder 10 has an inlet 11 for the incoming fiber air flow. The fiber air stream is opened in the respective relevant section 12 in a known manner. The loose fibers thus opened are fed to the correspondingly relevant weighing section 20. The weighing section 20 is located behind a cover plate 24 which is correspondingly located in the front here.

[0036] An additional box feeder 2 is arranged on the left side of the feeder 10, which also opens the incoming fiber material and delivers it to the relevant weighing section 20.

[0037] There is a receiving section 30 below the three weighing sections 20, 20, 20 here. The containing section 30 is used to transport the fiber material unloaded from the weighing section 20 toward the outlet 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com