Binder used for lithium ion battery anode, lithium ion battery anode using the same and preparation method thereof

A lithium-ion battery and binder technology, which is applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of pole piece structure changes, shedding of pole piece active materials, weak adhesion, etc. The effect of prolonging the service life, stable electrochemical performance and reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

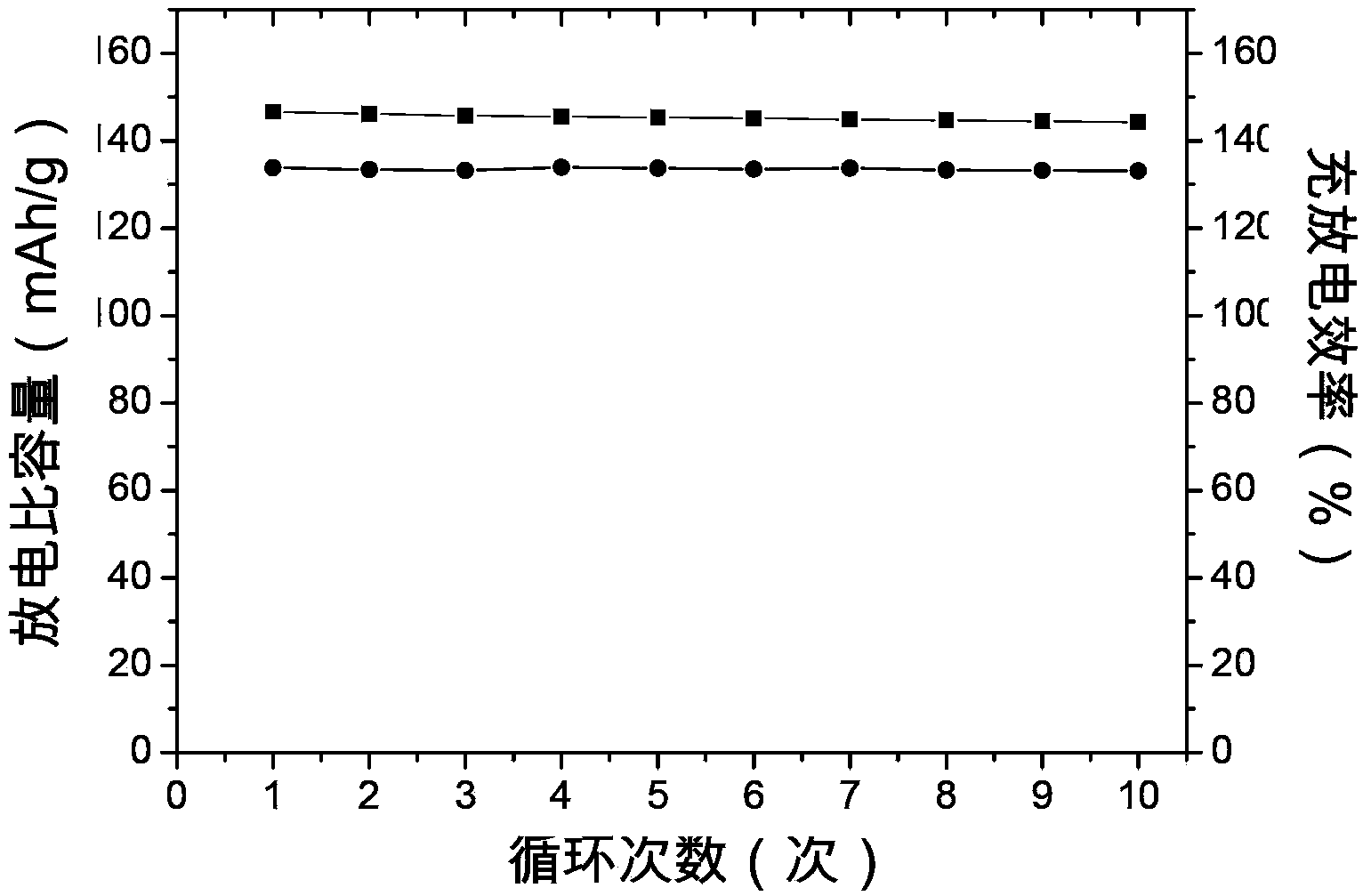

Examples

Embodiment 1

[0033] In this embodiment, the binder for the positive electrode of a lithium ion battery is a fluorine-containing lithium sulfonate side group CF 2 CF 2 O(CF 2 ) 2 SO 3 Li's polyether ether ketone has the following structural formula:

[0034]

[0035] The preparation method of the binder is: fluorine-containing sulfonic acid CF 2 CF 2 O(CF 2 ) 2 SO 3 The polyether ether ketone powder with H side group was immersed in 1M LiOH aqueous solution, stirred and lithiated for 12 hours, filtered and washed with deionized water to neutrality, and dried thoroughly in a vacuum drying oven at 80°C to obtain the powder The material is CF 2 CF 2 O(CF 2 ) 2 SO 3 Li's polyetheretherketone binder, put it in the desiccator for later use.

[0036] The positive electrode of a lithium ion battery using the above-mentioned binder includes a current collector aluminum foil and an active material layer coated on the surface of the current collector aluminum foil. The active material layer includes lithium...

Embodiment 2

[0045] In this embodiment, the binder for the positive electrode of a lithium ion battery is a fluorine-containing lithium sulfonate side group CF 2 CF 2 O(CF 2 ) 2 SO 3 Li's polysulfone, its structural formula is as follows:

[0046]

[0047] The preparation method of the binder is: fluorine-containing sulfonic acid side group CF 2 CF 2 O(CF 2 ) 2 SO 3 The polysulfone powder of H was immersed in 1M LiOH aqueous solution, stirred for 12h, and then filtered and washed with deionized water to neutrality. The powder was thoroughly dried in a vacuum drying oven at 80°C. The obtained powder was Pendant Lithium Fluorosulfonate CF 2 CF 2 O(CF 2 ) 2 SO 3 Li's polysulfone binder, put it in the desiccator for later use.

[0048] The positive electrode of a lithium ion battery using the above-mentioned binder includes a current collector aluminum foil and an active material layer coated on the surface of the current collector aluminum foil, and the active material layer includes LiCoO 2 The po...

Embodiment 3

[0052] In this embodiment, the binder for the positive electrode of the lithium ion battery is the same as the binder used for the positive electrode of the lithium ion battery in Example 1, and is a fluorine-containing lithium sulfonate side group CF 2 CF 2 O(CF 2 ) 2 SO 3 Li's polyether ether ketone, its structural formula is also:

[0053]

[0054] The preparation method of the binder is the same as the preparation method of the binder in Example 1.

[0055] The positive electrode of a lithium ion battery using the above-mentioned binder includes a current collector aluminum foil and an active material layer coated on the surface of the current collector aluminum foil, and the active material layer includes LiMn 2 O 4 The powder is used as a positive electrode active material, acetylene black is used as a conductive agent, and the above-mentioned fluorine-containing lithium sulfonate side group CF 2 CF 2 O(CF 2 ) 2 SO 3 Li polyether ether ketone is used as the binder, and the prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com