Independent pitch system and pitch method based on electric effective damping

A technology of independent pitch change and electric damping, applied in the field of pitch control system, can solve problems such as inability to effectively maintain electric power and multi-objective control of wind rotors, inability to effectively reduce electric power fluctuations, and reduce the overall operation reliability of wind turbines, so as to improve wind energy Utilization rate, reduction of dynamic balance load, reduction of stress shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

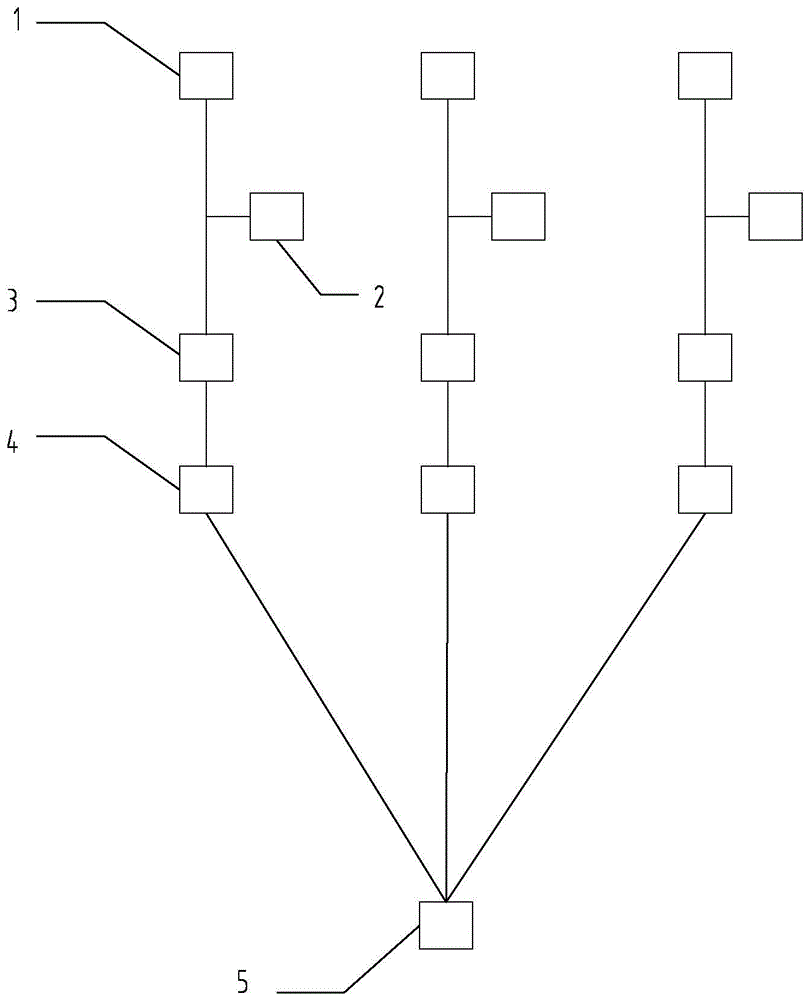

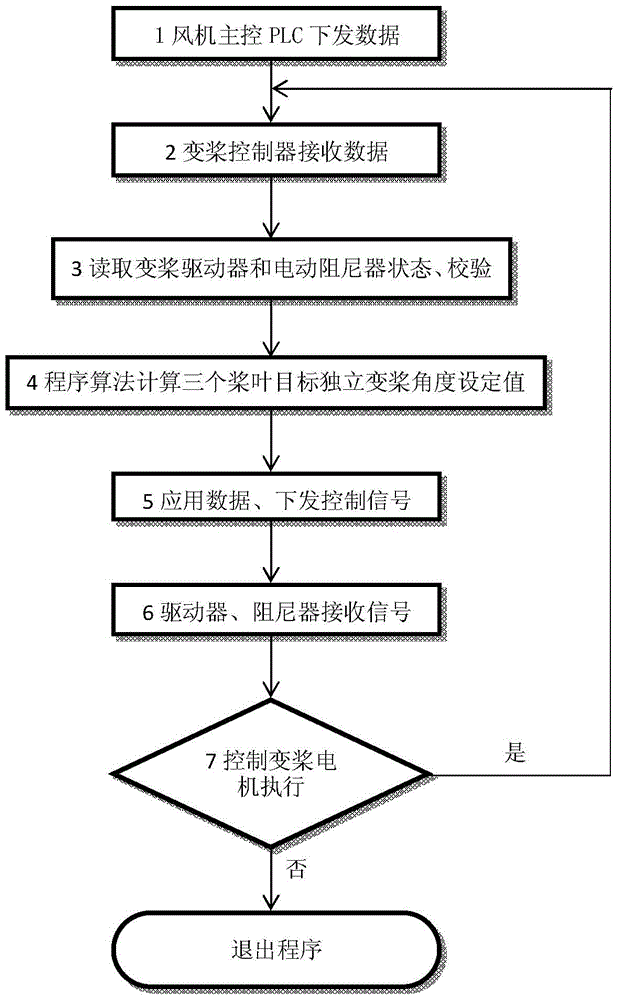

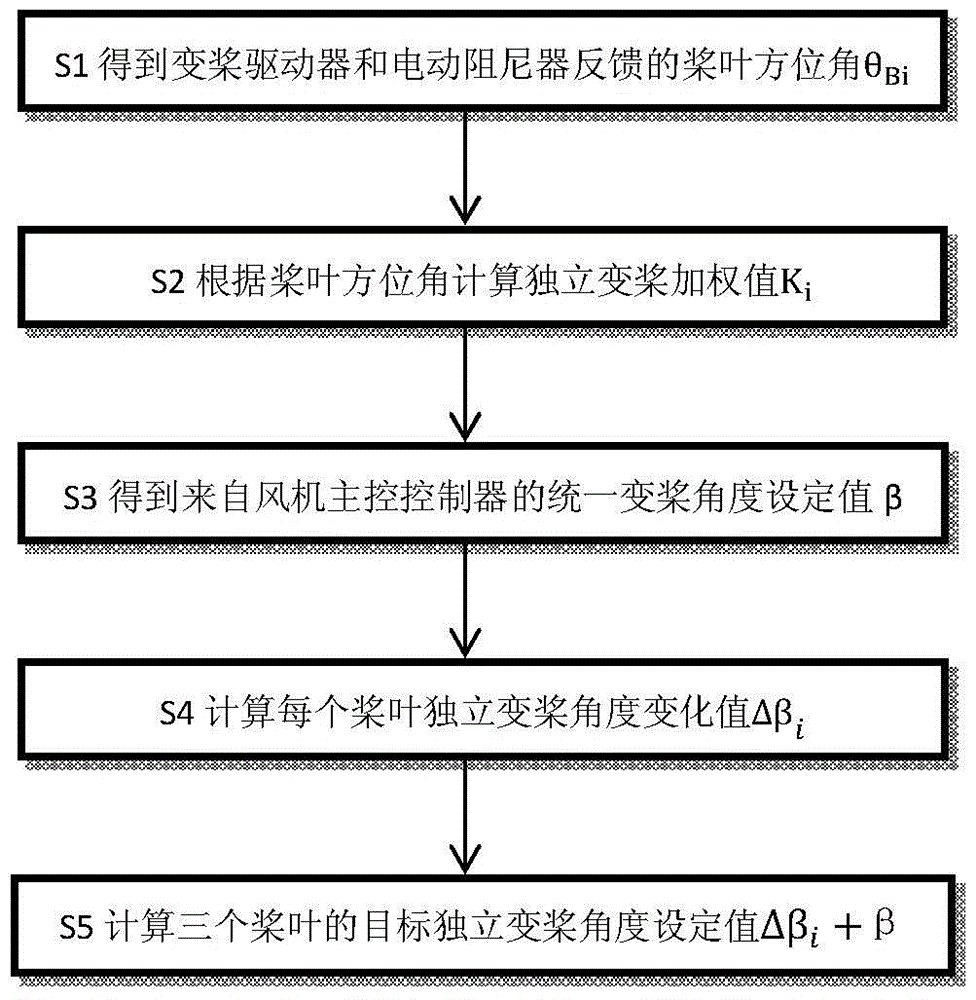

[0043] Example: such as figure 1 As shown, each of the blades has an independent pitch device, the pitch device includes a pitch controller 4, a pitch driver 3, an electric damper 2 and a pitch motor 1, and the pitch driver 3 is respectively The pitch motor 1 and the electric damper 2 are connected, the pitch controller 4 is connected to the pitch driver 3, and the three pitch drivers 3 are respectively connected to the fan master controller 5.

[0044] Among them, the pitch motor 1 is used as an actuator, which can actually drive the blades of the fan to rotate, and its power is provided by the pitch driver 3. The electric damper 2 is connected between the pitch motor 1 and the pitch driver 3, and the electric damper 2 Provide electric effective damping when the pitch motor 1 operates, and the electric damper 2 also detects the running state of the pitch motor 1 in real time, and receives feedback signals by controlling the pitch driver 3 and the electric damper 2, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com