A two-stage seal bumper fishable completion device for horizontal wells

A technology for horizontal wells and salvage devices, which is used in wellbore/well valve devices, sealing/packing, wellbore/well components, etc. Pressure bearing capacity, improve diameter expansion rate, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

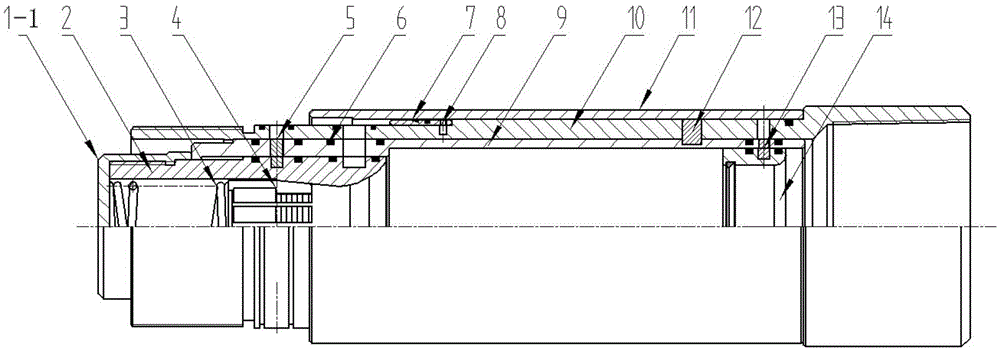

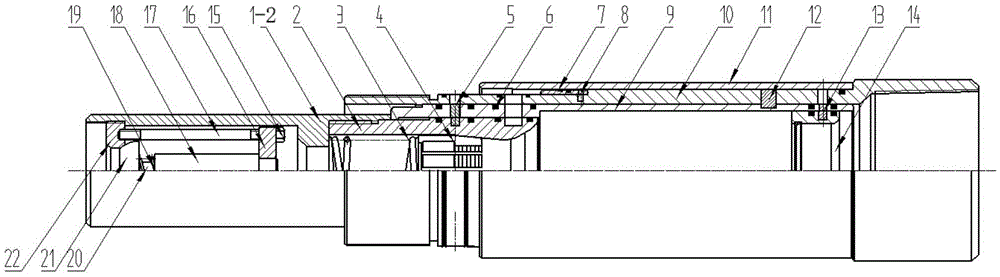

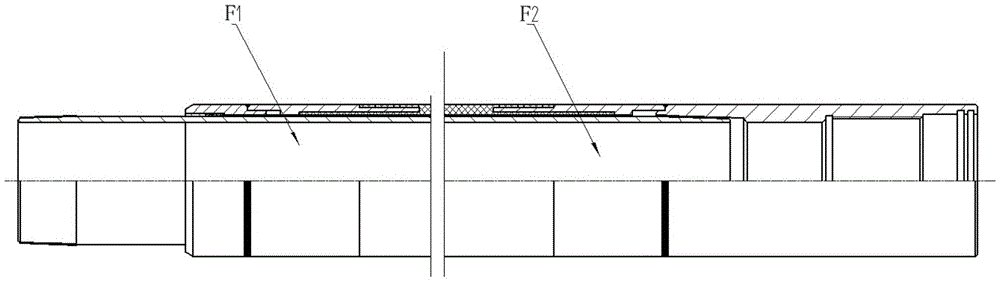

[0065] The present invention will be further described below in conjunction with the accompanying drawings.

[0066] Horizontal well double-stage seal bumper fishable completion device, including no-drilling plug device, bumper rubber plug and fishing device, said no-drill plug device includes a cementing switch and a packer; the upper end of the cementing switch It is connected with the casing, the lower end of the cement injection switch is connected with the upper end of the packer, and the lower end of the packer is connected with the screen pipe.

[0067] The cement injection switch is a single-flow valve type cement injection switch. The check valve type cementing switch includes a check valve 1-2, a bump seat 14, a spring 3, a slip 4 and a cylinder between them, and the cylinder is an inner cylinder from inside to outside. 9. The upper joint 10 and the outer cylinder 11, the end of the upper joint 10 close to the one-way valve seat 1-2 is provided with a closing sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com