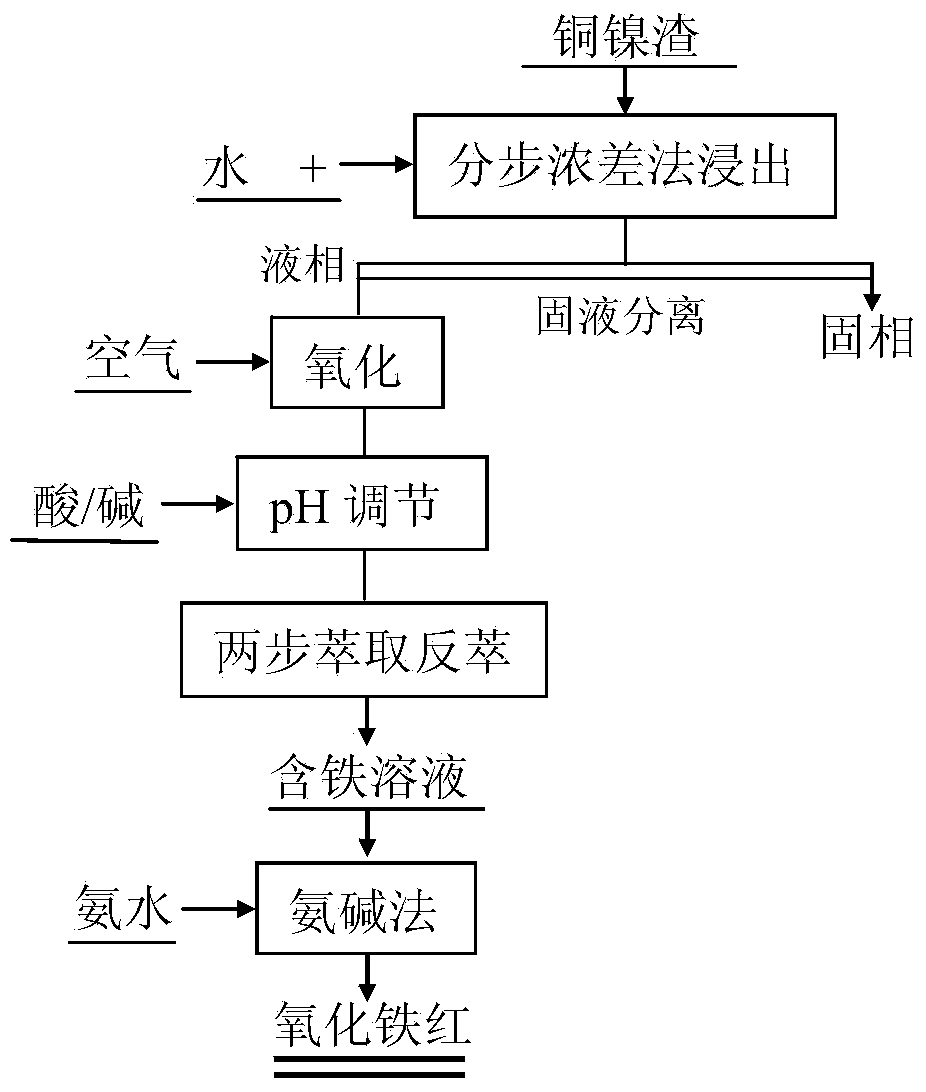

Method for preparing iron oxide red by using copper nickel slag

A technology for red iron oxide and copper-nickel slag is applied in the field of mineral resource recycling, which can solve the problems of non-recycling of pickling waste liquid, high roasting temperature and complicated process, and achieve fast and effective solid-liquid separation and high product purity. , the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

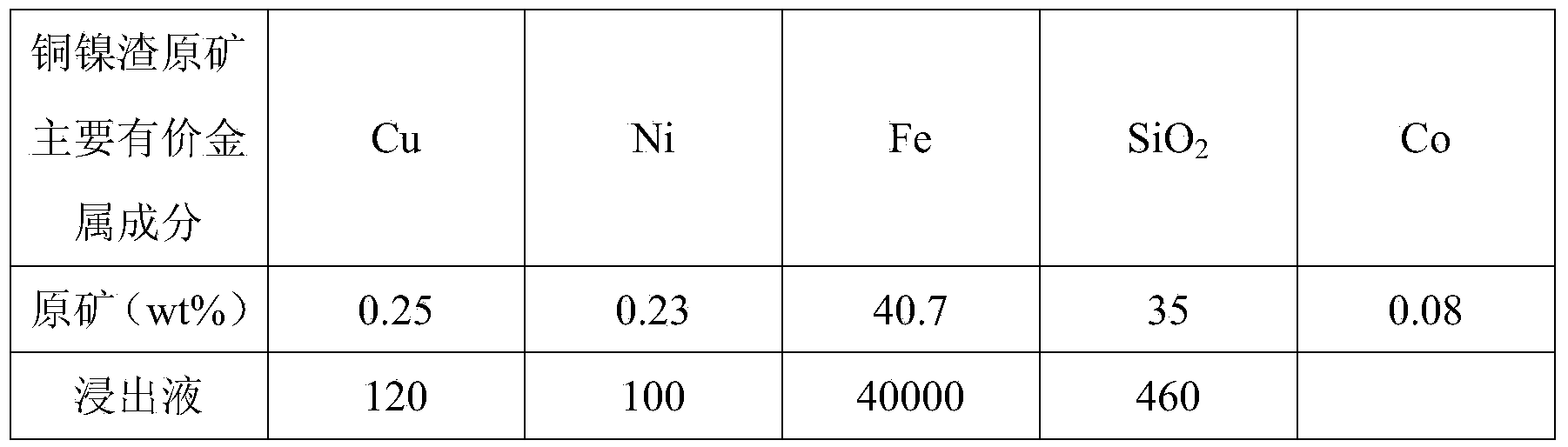

[0051] Step 1: adopt the closed-circuit grinding scheme, feed the copper-nickel slag through the vibrating feeder, and send it into the mill by the belt conveyor; after reaching the particle size requirement of 70-75%-80 mesh, it is lifted by the screw conveyor and bucket The machine is lifted to the powder silo for standby; the main component content of the copper-nickel slag is shown in Table 1; the copper waste slag that has been ground in the powder silo is weighed and then added to the first-stage leaching tank, and water is added in proportion. and sulfuric acid, the amount of sulfuric acid added is 1.1 times the theoretical molar amount of iron in the copper-nickel slag, the mass percentage concentration of sulfuric acid in the pulp is maintained at 80% during leaching, and the temperature is 50°C for 30 minutes; the pulp that has been leached in the first stage Quickly pour into the second-stage stirring leaching tank, and at the same time add water in proportion to kee...

Embodiment 2

[0060] Step 1: adopt the closed-circuit grinding scheme, feed the copper-nickel slag through the vibrating feeder, and send it into the mill by the belt conveyor; after reaching the particle size requirement of 70-75%-200 mesh, it is lifted by the screw conveyor and bucket The machine is lifted to the powder silo for standby. The main component content of copper-nickel slag is shown in Table 2; weigh 100kg of the copper waste slag that has been ground in the powder silo and add it to the first-stage leaching tank, and add water and hydrochloric acid in proportion at the same time. The amount of hydrochloric acid added is The theoretical molar amount of iron in copper-nickel slag is 0.9 times, and the mass percentage concentration of hydrochloric acid in the pulp is kept at 35% during leaching, and the temperature is 70°C for 30 minutes; the pulp that has been leached in the first stage is quickly poured into the second stage for stirring At the same time, water is added in pro...

Embodiment 3

[0068] Step 1: adopt the closed-circuit grinding scheme, feed the copper-nickel slag through the vibrating feeder, and send it into the mill by the belt conveyor; after reaching the particle size requirement of 80-85%-325 mesh, it is lifted by the screw conveyor and bucket The machine is lifted to the powder silo for standby use; the main component content of the copper-nickel slag is shown in Table 3; 100 kg of copper waste slag that has been ground in the powder silo is weighed and then added to the first-stage leaching tank, and simultaneously added in proportion Water and nitric acid, the amount of nitric acid added is 1.4 times the theoretical molar amount of iron in the copper-nickel slag, the mass percentage concentration of nitric acid in the pulp is maintained at 50% during leaching, and the temperature is 70 °C for 90 minutes; the first-stage leached The ore pulp is quickly poured into the second-stage stirring leaching tank, and water is added in proportion at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com