Lithium accumulator

A lithium battery and electrode technology, applied in the direction of lithium battery, battery, battery electrode, etc., can solve the problems of increasing the volume and capacity of battery cells, unable to realize the separator, etc., to reduce the charge and discharge cycle, high volume capacity, low resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

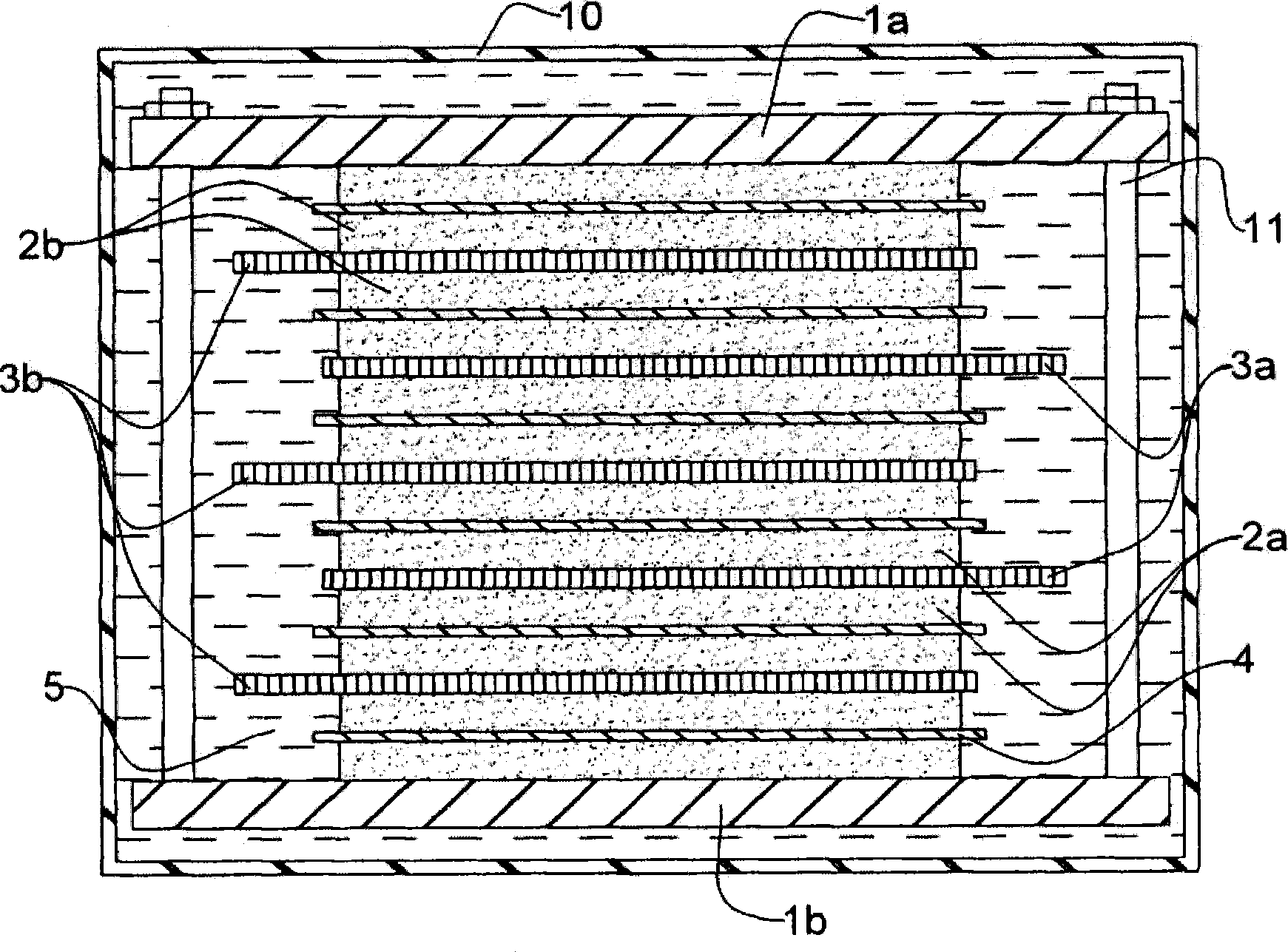

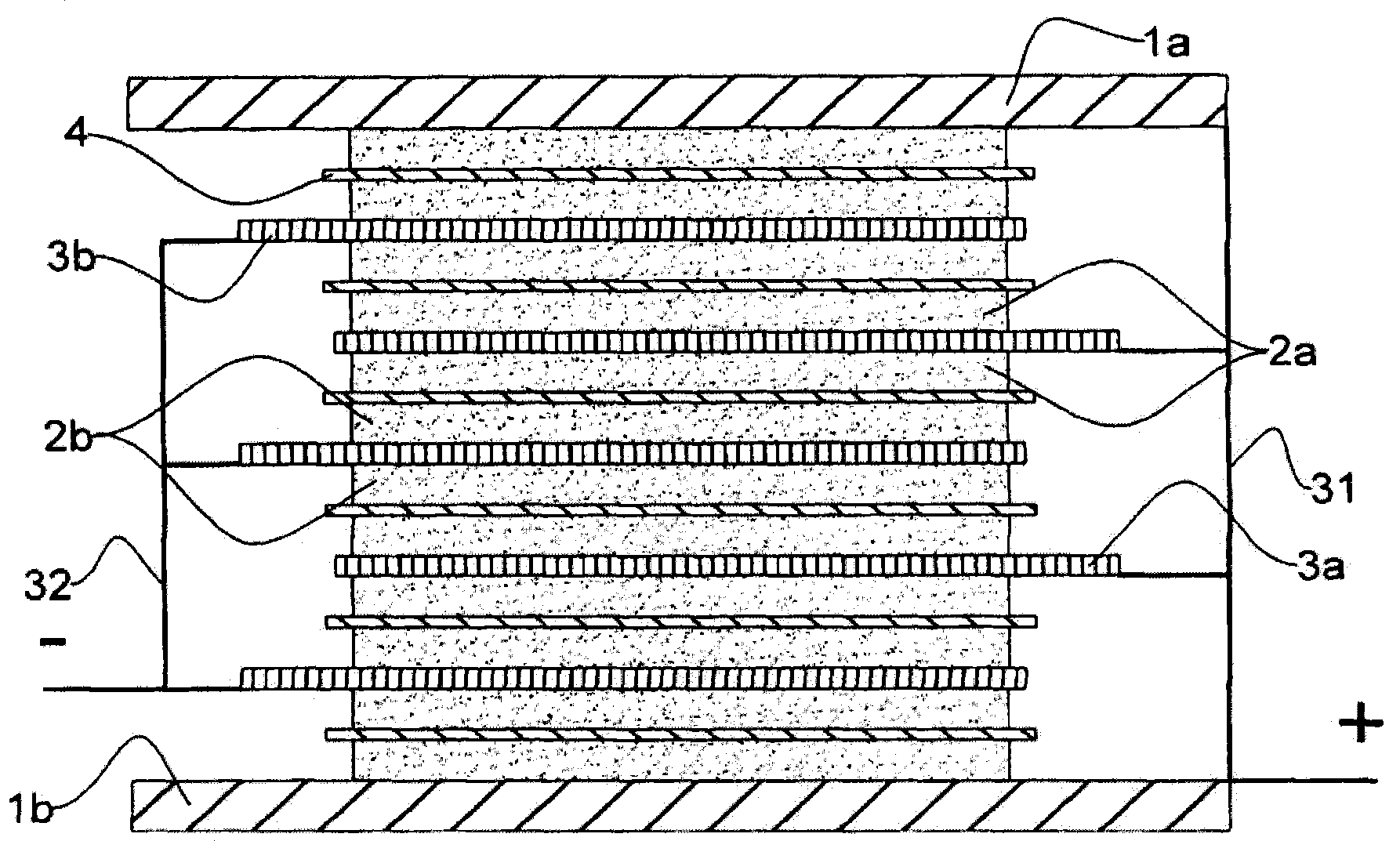

[0034] Depend on figure 1 The accumulator shown in a schematic sectional view comprises a housing 10 in which the individual accumulator cells are arranged in a superposition above one another between edge covers 1a, 1b. The battery cells are fastened together by bolts 11 . Each cell consists of a positive electrode 2a, a negative electrode 2b and a separator 4 between the electrodes. Each positive electrode 2a is pressed into a current collector 3a and each negative electrode 2b is pressed into a current collector 3b. The material of each electrode, free of organic binders, is pressed into the current collector without any frame, but with certain protrusions so that the electrodes extend above and below the surface of the current collector so that there is a gap between the opposing outer electrode surfaces. The minimum distance between them is equal to at least 3 times the thickness of the current collectors 3a, 3b.

[0035] The inner space of the battery case 10 and the ...

example 2

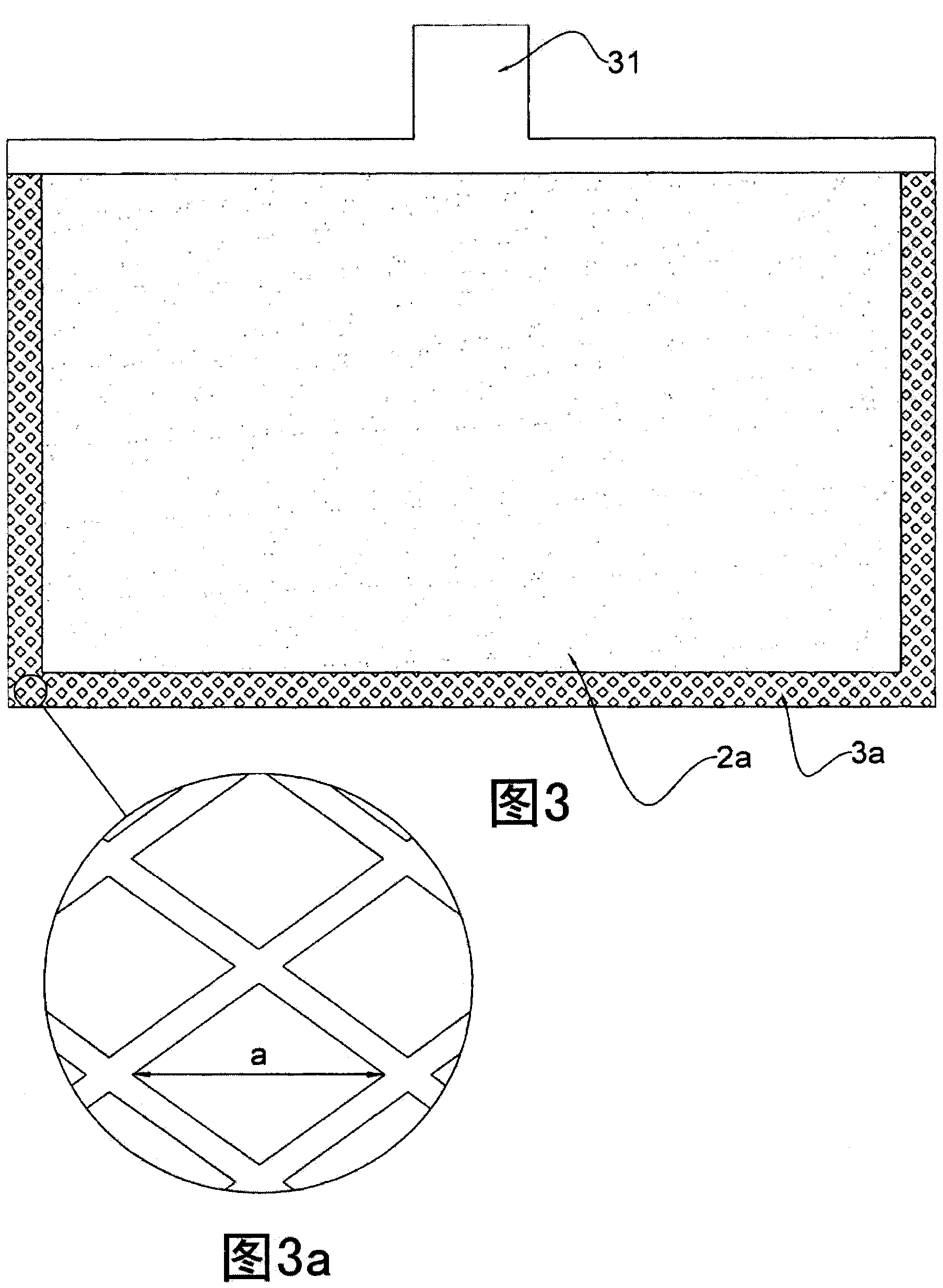

[0038] The lithium storage battery consists of 13 negative electrodes 2 b and 14 positive electrodes 2 a separated from each other by separators 4 . Each electrode has an area of 2 x 25 mm and a thickness of 0.3 to 0.35 mm. The positive electrode is made of 80% LiFePO by weight 4 (Life -P2(LFP)), further 10wt% electronically conductive carbon and 10wt% electrically conductive compressible carbon with bonding properties when compressed, the LiFePO 4Small aggregate morphology with typical size below 2 μm with LFP particles of about 200 nm is present. This type of carbon, sold separately under the trade name Ketjen Black EC-300J, has a specific surface area of 800 m 2 / g, the specific pore volume is 310-345ml / 100g, the aggregate size is mainly above 150nm and the density is 125-145kg / m 3 . In addition, carbons sold separately under the trade names EC-600JD and EC-330JMA can be used. Carbon at about 25kN / cm 2 Pressed tightly on the meshed aluminum metal current collect...

example 3

[0045] The lithium secondary battery consists of 12 negative electrodes 2 b and 13 positive electrodes 2 a separated from each other by separators 4 . The separator is made of ceramic powder Al 2 o 3 and glass fiber mixture, with a thickness of 80 μm. The active material of the positive electrode is LiCo 1 / 3 mn 1 / 3 Ni 1 / 3 o 2 (NMC) and the active material of the negative electrode is Li in the form of nanoparticles 4 Ti 5 o 12 (LTS). The area of each electrode is 2×25mm, and its thickness is 0.3-0.35mm. The volume of the battery module is 3.25cm 3 And its specific capacity is 162Wh / liter.

[0046] The positive electrode consisted of 80 wt% NMC with a hollow spherical morphology with a size below 40 μm, with a typical wall thickness below 5 μm and an average NMC particle size of 250 nm, and another 20 wt% electronically conductive carbon. The mixture was compacted as in Example 2 on a 0.05 mm thick current collector-mesh aluminum metal with a maximum pore size 'a'...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com