Hot rolling equipment

A technology for equipment and rolling mills, applied in the field of hot rolling equipment, can solve problems such as poor shape, lowering of intermediate billet temperature, and quality damage, and achieve the effect of ensuring stability, uniform temperature difference, and preventing damage to quality or productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

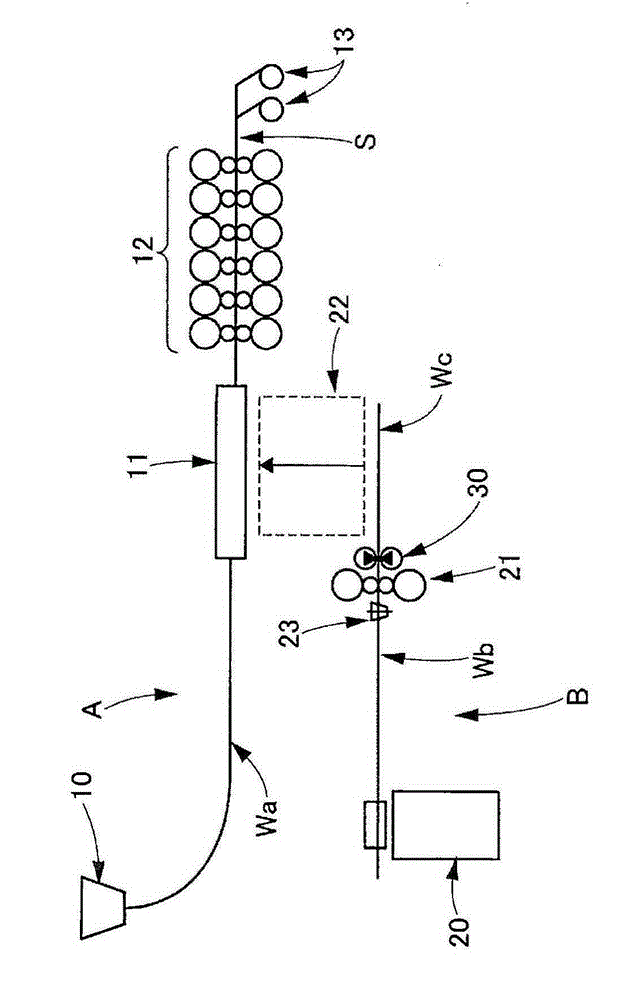

[0022] figure 1 It is a side view showing the schematic structure of the hot rolling facility according to Example 1 of the present invention.

[0023] like figure 1 As shown, molten steel is injected into a tundish from a ladle not shown, and is injected into the continuous casting machine 10 from the tundish. In this continuous casting machine 10, molten steel solidifies to become a high-temperature thin slab Wa (for example, about 70 to 100 mm). The thin slab Wa advances to the soaking furnace (continuous casting machine output side furnace) 11, and the temperature drop of the thin slab Wa is suppressed in the soaking furnace 11, and the temperature distribution in the thin slab Wa is uniformized. In addition, a cutting machine (not shown) that cuts the slab when it reaches a desired length is provided on the output side of the continuous casting machine 10 .

[0024] The thin slab Wa coming out of the soaking furnace 11 is finished rolled by a plurality of (in the illus...

Embodiment 2

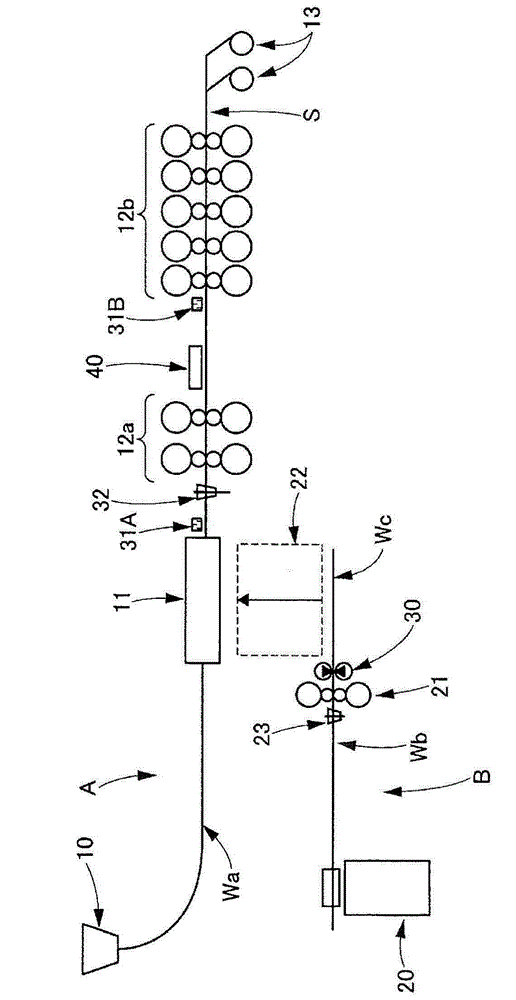

[0032] figure 2 It is a side view showing a schematic structure of a hot rolling facility according to Example 2 of the present invention.

[0033] like figure 2 As shown, this embodiment is an example in which the plurality of rolling mills (columns) 12 of the first rolling line A in Embodiment 1 are divided into one or more stands (in the illustrated example, two stands) The upstream side rolling mill 12a consisting of one stand) and the downstream side rolling mill 12b consisting of more than one stand (five stands in the illustrated example) are located on the intermediate table between the above-mentioned upstream side rolling mill 12a and the downstream side rolling mill 12b. A material temperature adjusting device 40 is provided which adjusts the temperature of the slab (thin slab Wa or intermediate slab Wc) rolled by the upstream side rolling mill 12a by cooling water or a heating device or the like.

[0034]In other configurations, on the input side of the upstrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com